Clamp for bursting test of geosynthetic material and using method thereof

A geosynthetic material and testing technology, applied in analytical materials, measuring devices, instruments, etc., can solve the problems of high production cost, slippage of samples, poor controllability of pneumatic devices, etc., and achieve convenient operation, convenient loading and unloading, and controllable high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

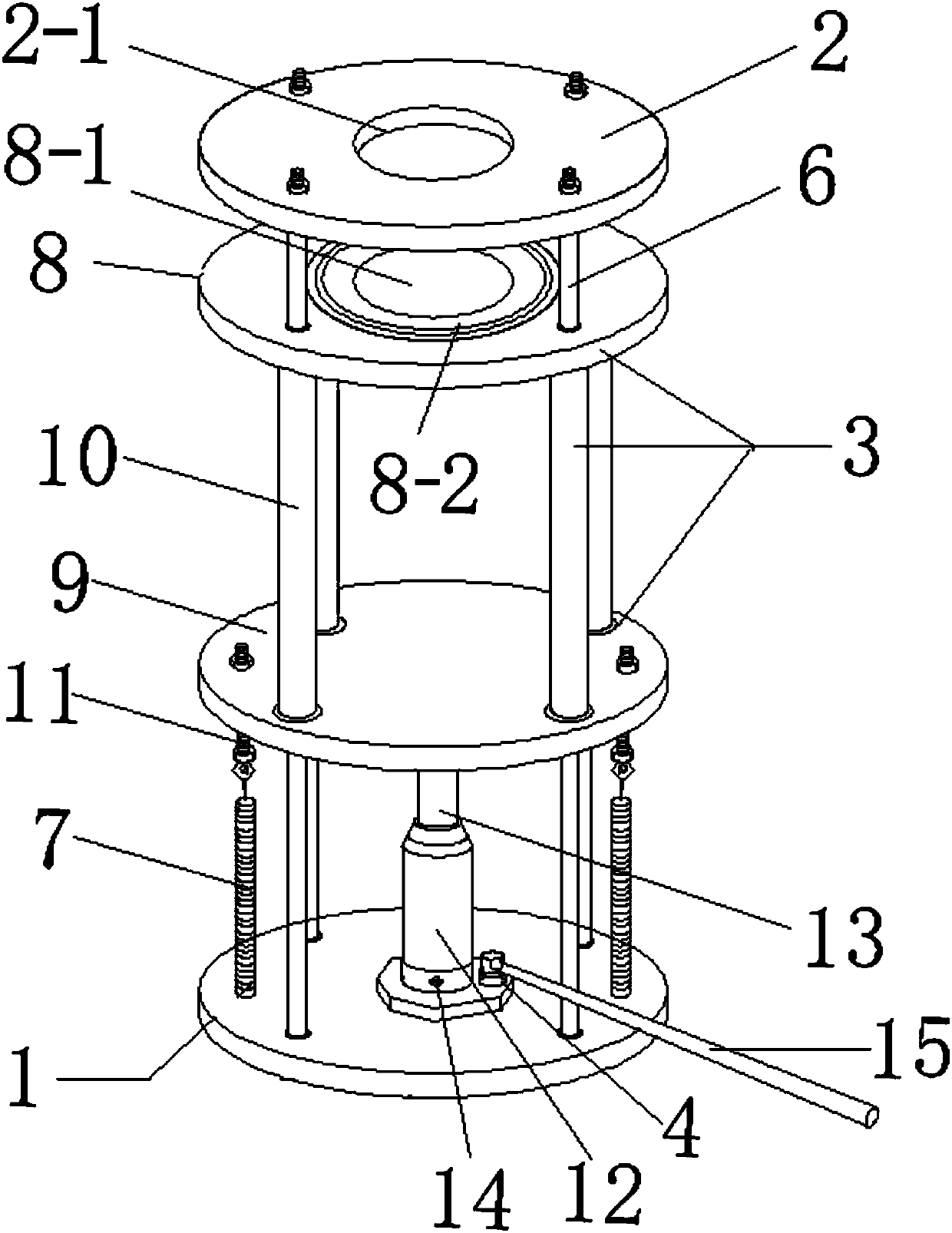

[0023] Such as figure 1 As shown, a geosynthetic material bursting test fixture includes a base 1, an upper splint 2, a movable lower splint 3 and a hydraulic jack 4,

[0024] The base 1 is disc-shaped, and four slide bars 6 are vertically arranged on the base 1, and two extension springs 7 are also arranged on the base 1;

[0025] The movable lower splint 3 is composed of a lower splint 8, a chassis 9, four hollow connecting rods 10, and hook bolts 11. The lower splint 8 and the chassis 9 are connected by the hollow connecting rods 10, and the positions of the four hollow connecting rods 10 are aligned with the four sliding The positions of the rods 6 are corresponding, and the inner diameter of the hollow connecting rod 10 is slightly larger than the diameter of the sliding rod 6, so that the four hollow connecting rods 10 can be slidably inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com