Gas distribution mechanism double friction pair composite simulation experiment system

A composite simulation and gas distribution mechanism technology, which is applied in the testing of machine/structural components, internal combustion engine testing, and testing of mechanical components, etc. It can solve problems such as failure to adopt part-level tests and lack of research work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

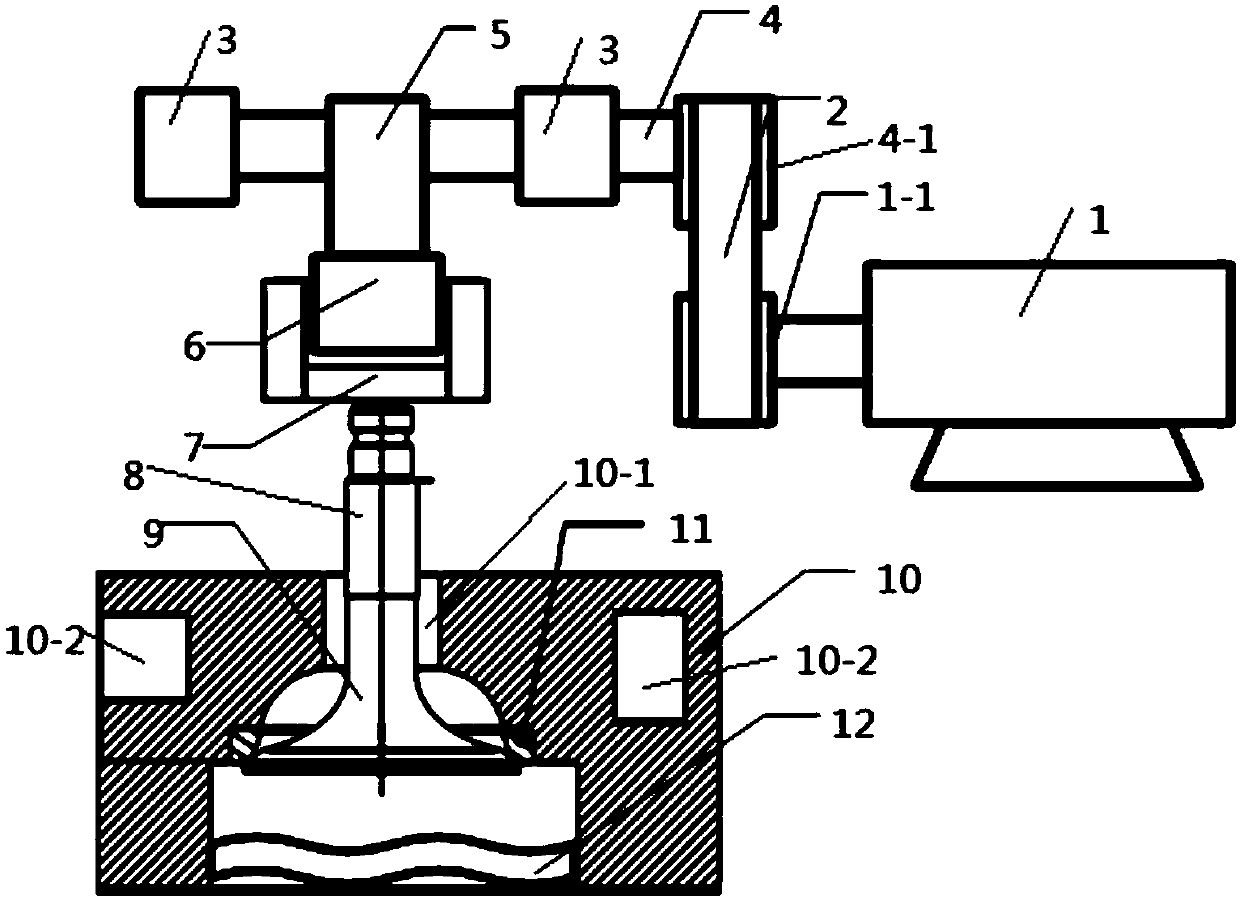

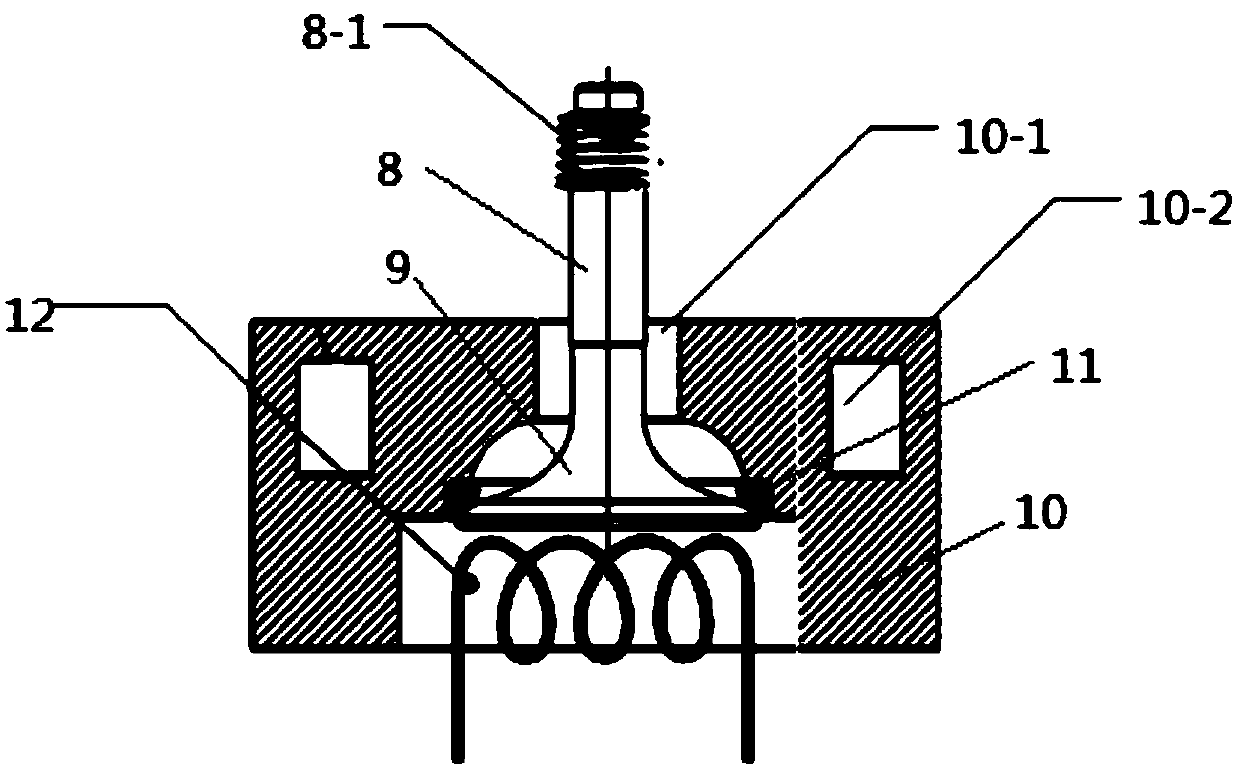

[0017] Such as Figure 1 to Figure 2 As shown, the present invention is a compound simulation experiment system of double friction pairs of valve mechanism, which realizes the wear test of two pairs of friction pairs at the same time, has a stable and reliable structure, high efficiency, and the simulation is close to the actual working conditions, and the experimental data is powerful and reliable.

[0018] Specifically, if Figure 1 to Figure 2 As shown, it includes motor 1, belt 2, fixed shaft seat 3, camshaft 4, cam 5, roller 6, tappet body 7, valve push rod 8, valve 9, cylinder head 10, valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com