Detection device and method for calculating raw material consumption and transport efficiency

A technology for conveying efficiency and detection devices, which is applied to measuring devices, weighing equipment for materials with special properties/forms, instruments, etc., to achieve real-time detection of raw material consumption, easy installation, and simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

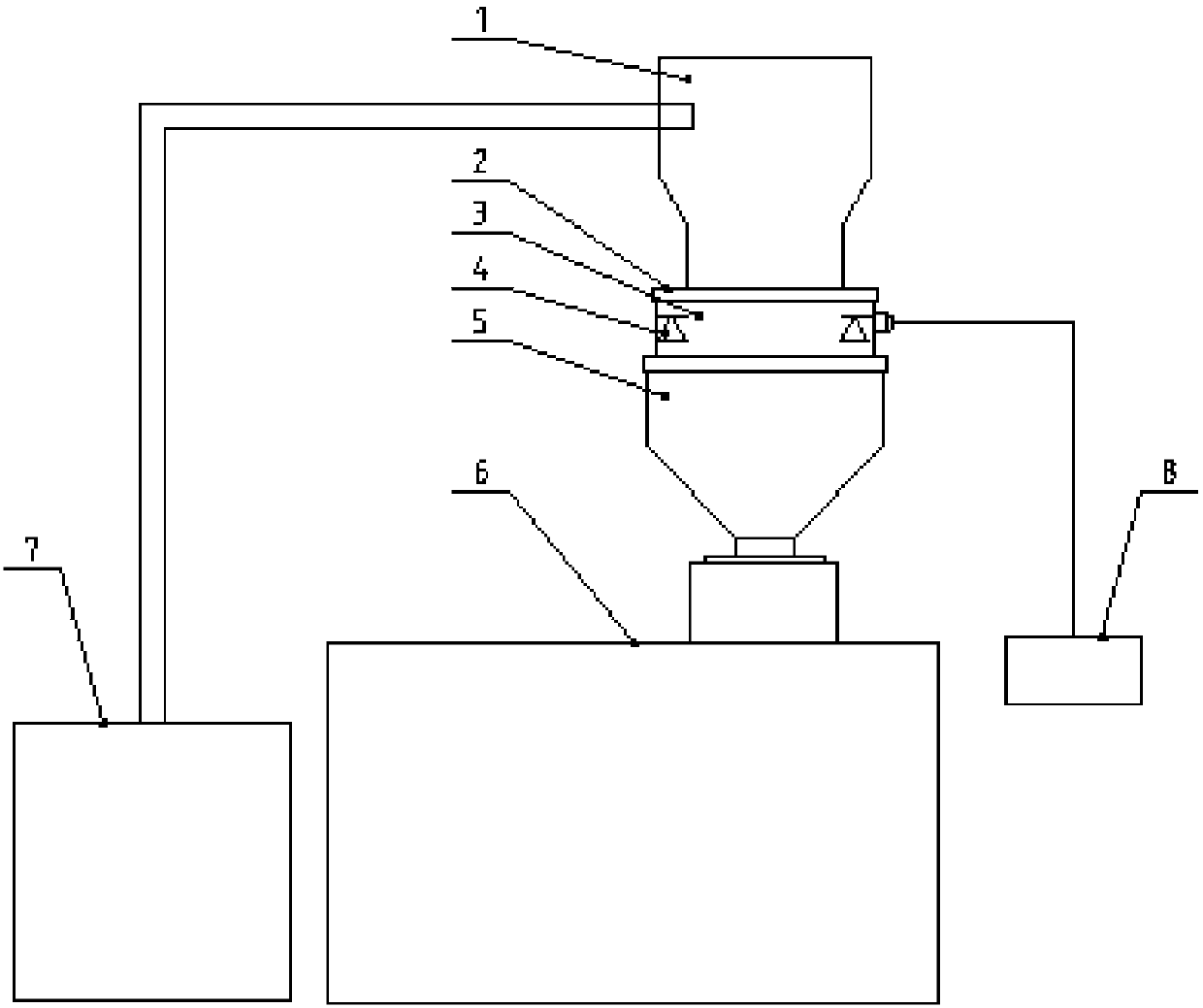

[0014] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following examples are combined figure 1 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0015] figure 1 It is a working principle diagram of a detection device and method for calculating raw material consumption and conveying efficiency of the present invention. Such as figure 1 As shown, the detection device for calculating raw material consumption and conveying efficiency provided by this embodiment includes: a suction machine 1 , a weighing device 2 , a material storage device 5 , an injection molding machine 6 and a silo 7 .

[0016] The upper part of the suction machine 1 is connected to the silo 7 through the pipeline, the lower part of the suction machine 1 is connected to the upper part of the weighing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com