Ship kitchen steam elimination device and working method

A steam and kitchen technology, which is applied in the field of ship galley steam elimination device and marine galley steam elimination device, can solve the problems of increased humidity in the room, waste of heat energy and fresh water resources, blurred vision of personnel, etc., and achieves remarkable effects and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

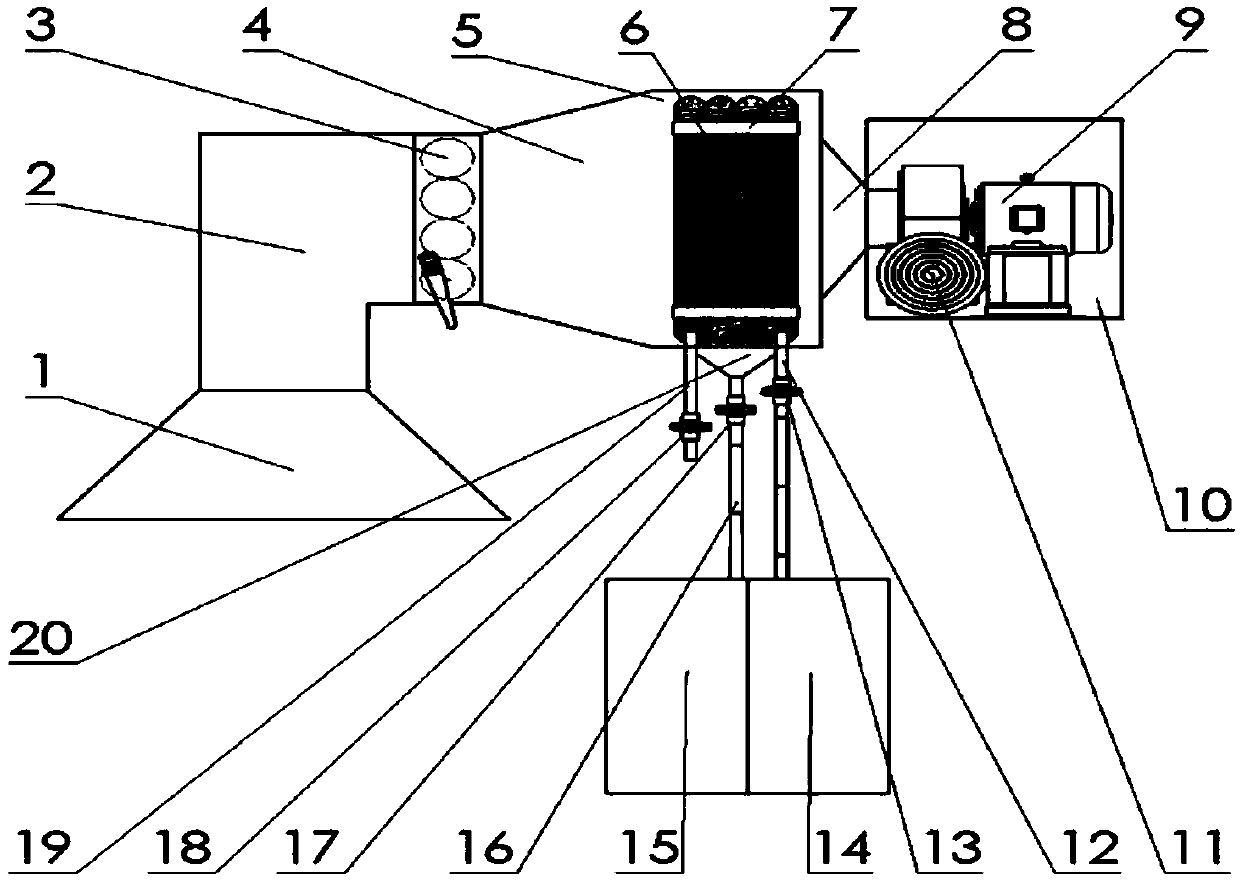

[0030] like figure 1 Shown: a steam elimination device for a ship galley, including a steam suction section, a condensation section and a discharge section. The steam suction section includes a suction reducer 1, a right-angle elbow 2, a damper 3, and a diffuser connected in sequence. 4. The condensing section includes a straight pipe 5 connected and sealed to the outlet end of the expander pipe 4 and a finned radiator 6 installed in the straight pipe 5 through a fixing frame 7. The finned radiator The outlet of the device 6 communicates with the first water tank 14 arranged below the straight pipe 5 through the first water pipe 12 equipped with the first valve 13, and the inlet of the finned radiator 6 passes through the first water pipe 12 equipped with the third valve 18. The three water pipes 19 communicate with the cold water supply end, and the bottom of the straight pipe 5 is provided with a conical collector 20, and the bottom of the conical collector 20 is connected w...

Embodiment 2

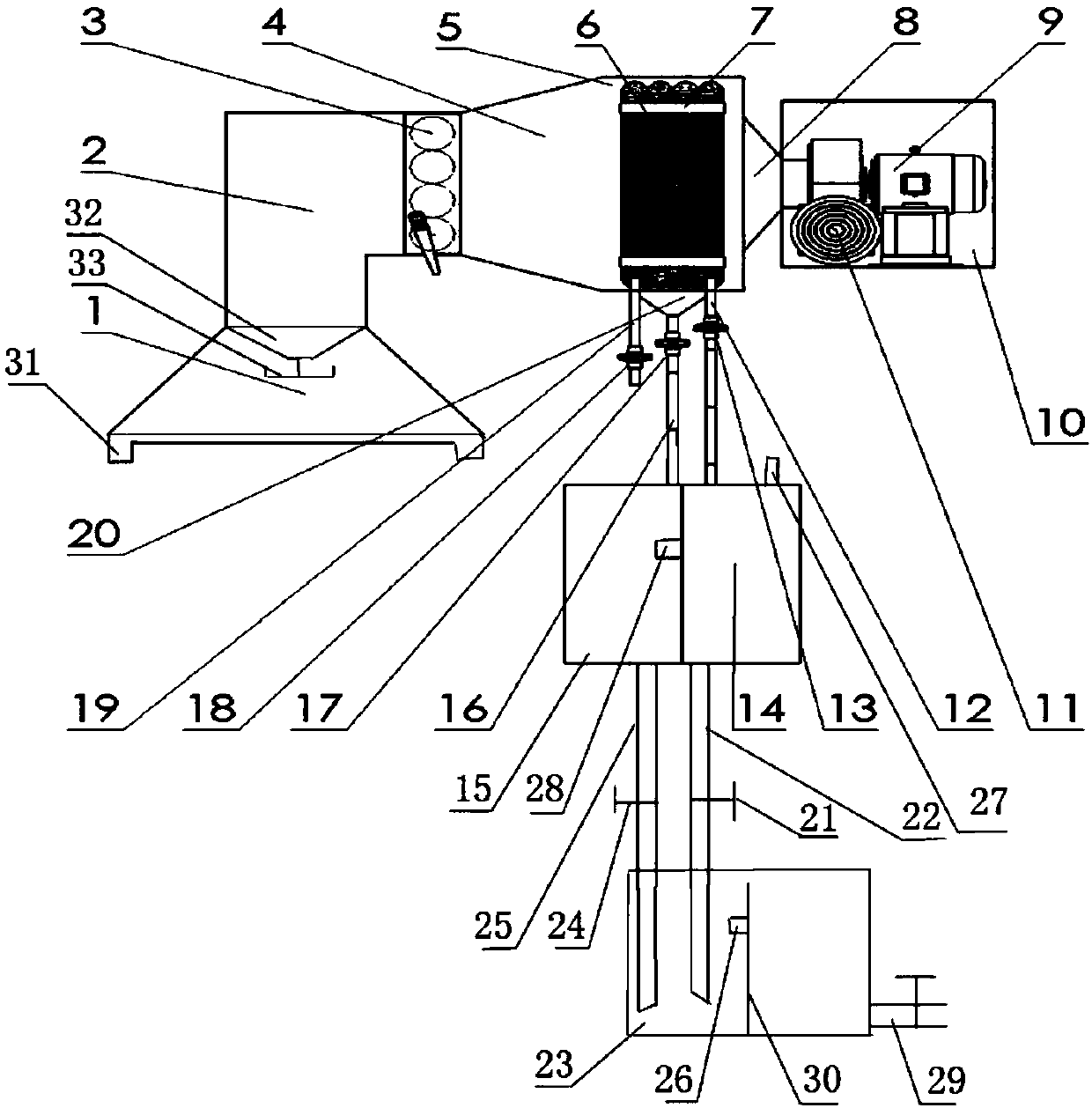

[0032] like figure 2 Shown: a steam elimination device for a ship galley, including a steam suction section, a condensation section and a discharge section. The steam suction section includes a suction reducer 1, a right-angle elbow 2, a damper 3, and a diffuser connected in sequence. 4. The condensing section includes a straight pipe 5 connected and sealed to the outlet end of the expander pipe 4 and a finned radiator 6 installed in the straight pipe 5 through a fixing frame 7. The finned radiator The outlet of the device 6 communicates with the first water tank 14 arranged below the straight pipe 5 through the first water pipe 12 equipped with the first valve 13, and the inlet of the finned radiator 6 passes through the first water pipe 12 equipped with the third valve 18. The three water pipes 19 communicate with the cold water supply end, and the bottom of the straight pipe 5 is provided with a conical collector 20, and the bottom of the conical collector 20 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com