A recovery method of high-grade ore body in deep collapse area

A recovery method and high-grade technology, applied in surface mining, mining equipment, earth-moving drilling, etc., can solve the problem that deep high-grade collapsed ore bodies cannot be safely and effectively recovered, and achieve good economic benefits, reasonable design, and guaranteed operation. the effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be further described below in conjunction with the accompanying drawings of the present invention and specific embodiments, and the described embodiments are only some of the embodiments of the present invention, not all of them.

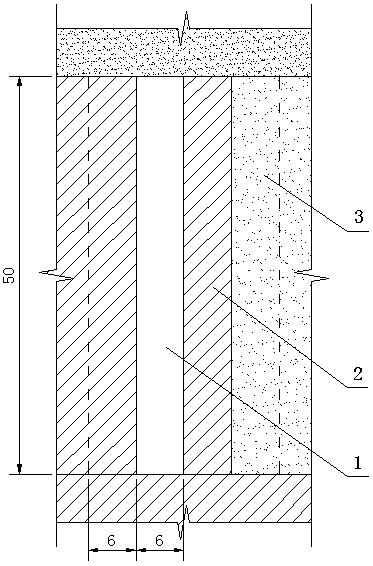

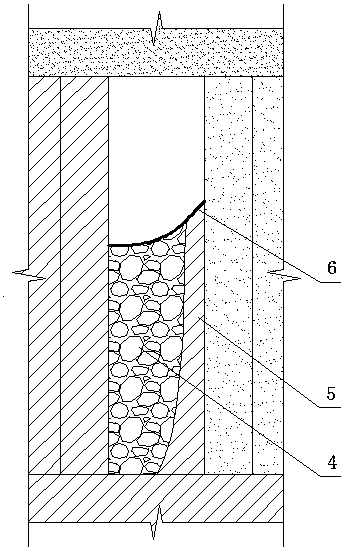

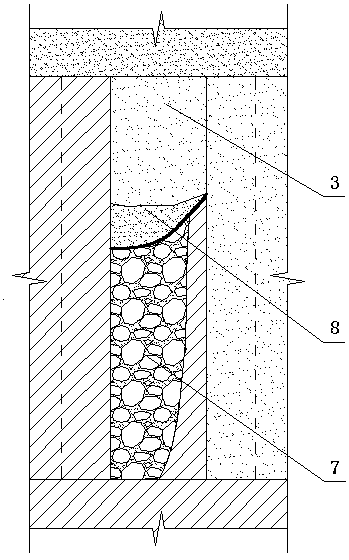

[0027] Such as Figure 1 to Figure 3 As shown, a lead-zinc deposit has high ore grade, the mining depth is 1000m from the surface, the ore body structure is broken, the fault fracture zone is developed, the stability is poor, and the stability of the surrounding rock is good. In order to meet the production task, a large-diameter deep hole side Go back to the ore mining method of collapsing. The structural parameters of the deep high-grade ore blocks are: the ore blocks are arranged vertically, the length of the ore body is generally 45m in thickness, 50m in height, and 6m in width. , after the mining is completed, the goaf 1 is filled with cemented filling materials wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com