Phase change energy storage microcapsules and preparation method thereof

A technology of phase change energy storage and microcapsules, which is applied in the direction of microcapsule preparations, preparation of microspheres, chemical instruments and methods, etc., can solve problems such as poor temperature resistance, leakage, and inability to adapt to high-temperature environments, and prevent flow and seepage leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for preparing phase change energy storage microcapsules comprises the following steps:

[0028] 1) Preparation of the core material emulsion: first mix attapulgite and paraffin to obtain a composite phase change material, the specific preparation process of the composite phase change material includes: A, firstly ultrasonically oscillates the attapulgite to disperse evenly, and then in ultrasonic stirring Add the molten paraffin drop by drop to the attapulgite to obtain the mixture under certain conditions; B. After the dropwise addition, oscillate the mixture ultrasonically for 45 minutes; C. Put it in a vacuum environment at 65°C and keep it warm for 12 hours.

[0029] Then add deionized water to the composite phase change material to make a saturated solution of the composite phase change material, the mixing mass ratio of the composite phase change material and deionized water is 1:1, and finally add an emulsifier to the composite phase change material sat...

Embodiment 2

[0036] The method for preparing phase change energy storage microcapsules comprises the following steps:

[0037] 1) Preparation of core material emulsion: firstly, porous silicon dioxide and octadecane are mixed to obtain a composite phase change material, and the specific preparation process of the composite phase change material includes: A, first ultrasonic vibration makes the porous silicon dioxide uniformly dispersed, and then Under the condition of ultrasonic stirring, molten octadecane was added dropwise to the porous silica to obtain a mixture; B. After the addition, the mixture was ultrasonically oscillated for 15 minutes; C. Placed in a vacuum environment at 55° C. for 13 hours.

[0038]Add deionized water to composite phase change material again to make composite phase change material saturated solution, the mixing mass ratio of composite phase change material and deionized water is 2:7, finally add emulsifier in composite phase change material saturated solution: ...

Embodiment 3

[0045] The method for preparing phase change energy storage microcapsules comprises the following steps:

[0046] 1) Preparation of the core material emulsion: first, diatomite and lauric acid are mixed to obtain a composite phase-change material. The specific preparation process of the composite phase-change material includes: A. First, ultrasonic vibration is used to disperse the diatomite evenly, and then ultrasonic stirring Add molten lauric acid drop by drop to diatomaceous earth under certain conditions to obtain a mixture; B. After the addition, ultrasonically oscillate the mixture for 35 minutes; C. Put it in a vacuum environment at 63°C and keep it warm for 14 hours.

[0047] Then add deionized water to the composite phase change material to make a saturated solution of the composite phase change material, the mixing mass ratio of the composite phase change material and deionized water is 1:2, and finally add an emulsifier to the composite phase change material saturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

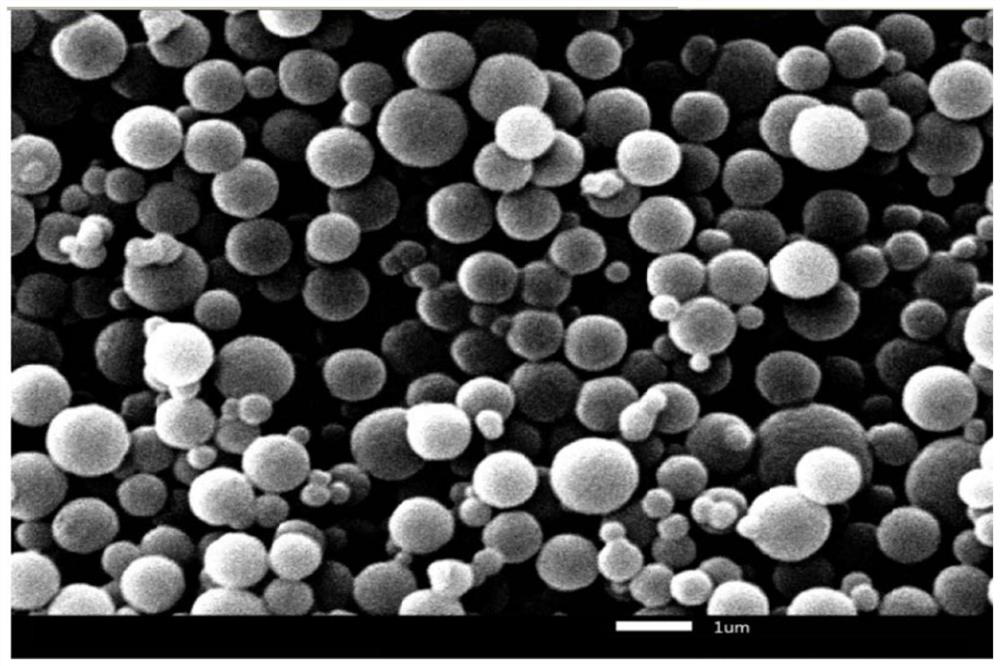

| particle size | aaaaa | aaaaa |

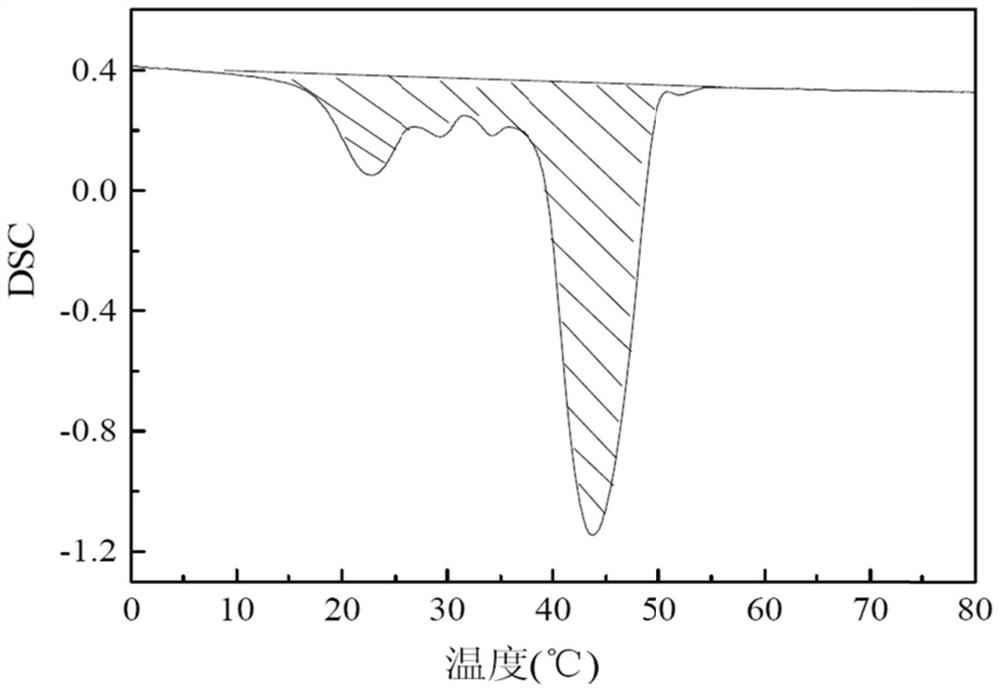

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com