Sandwich composite wall body prepared by utilizing industrial wastes and preparation method

A technology for industrial waste and composite walls, which is applied in the field of sandwich composite walls and its preparation, can solve problems such as external water seepage, environmental pollution, and fire induction, and achieve improved thermal insulation performance and fireproof performance, high tie strength, and energy saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

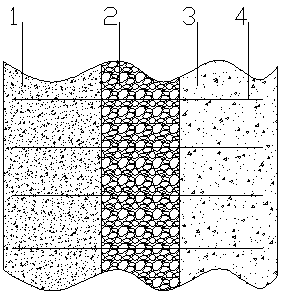

[0032] Such as figure 1 Shown is a sandwich composite wall made of industrial waste, including outer leaf wall 1, inner leaf wall 3, middle insulation layer 2 and connecting rod 4, the distance between the outer leaf wall and inner leaf wall, that is, the middle The thickness of the insulation layer is 1 / 4 of the total thickness of the composite wall. The outer leaf wall 1 and the inner leaf wall 3 are both made of concrete blocks and masonry mortar prepared from recycled construction waste aggregates, and the middle insulation layer 2 is made of waste particles of foamed plastic products, desulfurized building gypsum, chopped Fiber, polyvinyl alcohol, concrete waterproofing agent, physical foaming agent and water are mixed by metering, and poured after foaming. As a preferred solution, the physical foaming agent of this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com