Fertilizer mixing device applied to fertilizer production

A technology of mixing device and fertilizer, applied in mixers, chemical instruments and methods, dissolving and other directions, can solve the problems of low efficiency, high crushing intensity, large labor load, etc., and achieve easy installation and use, prolong service life, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

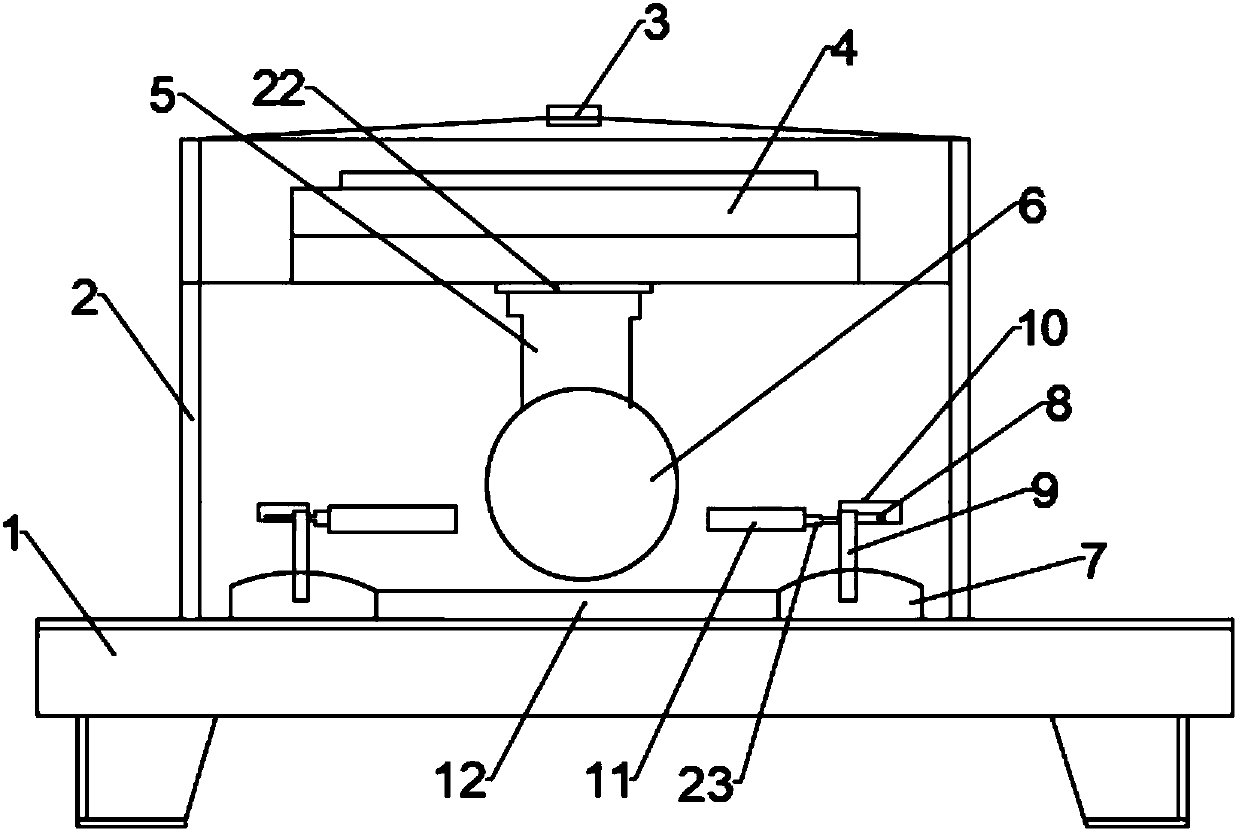

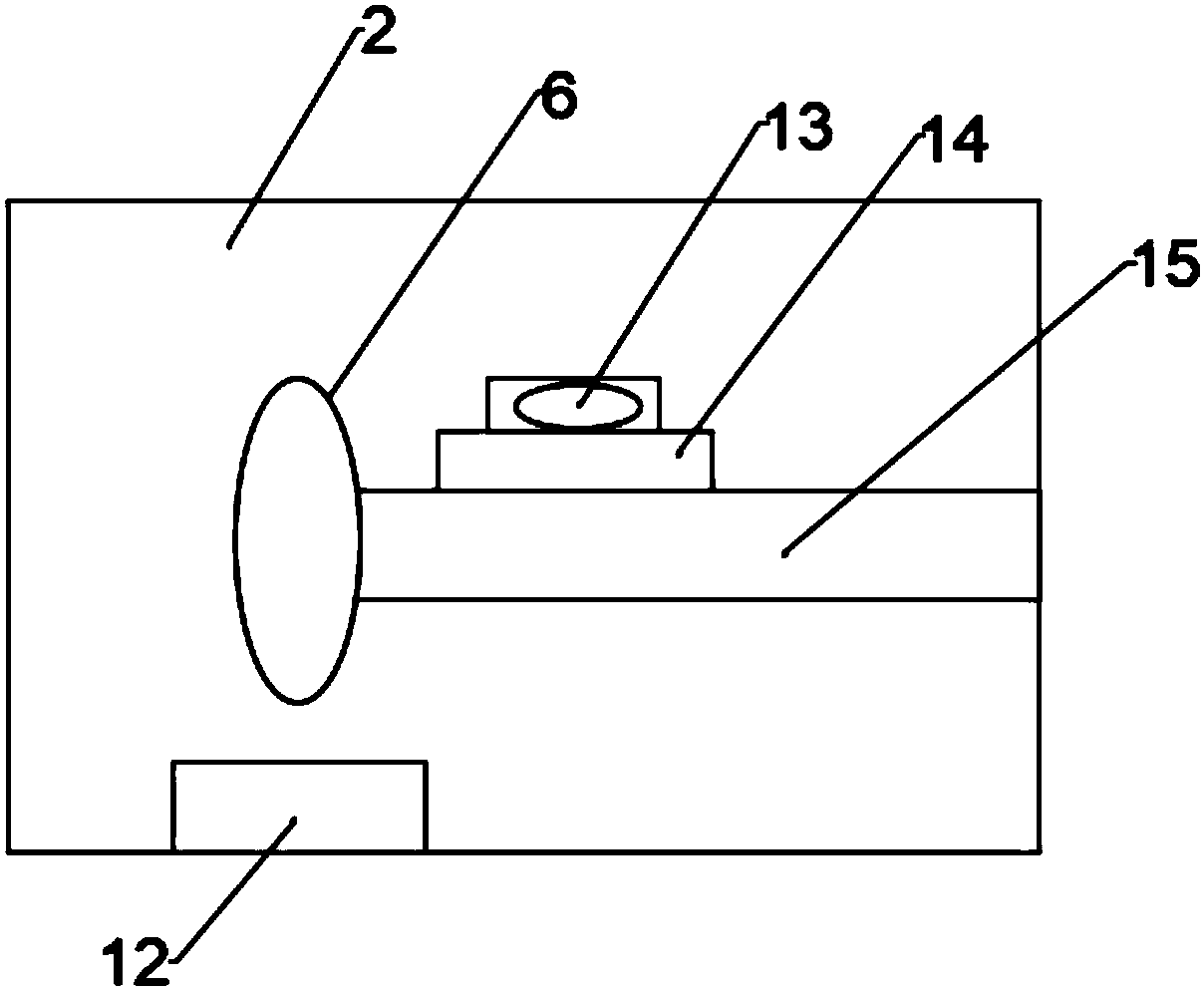

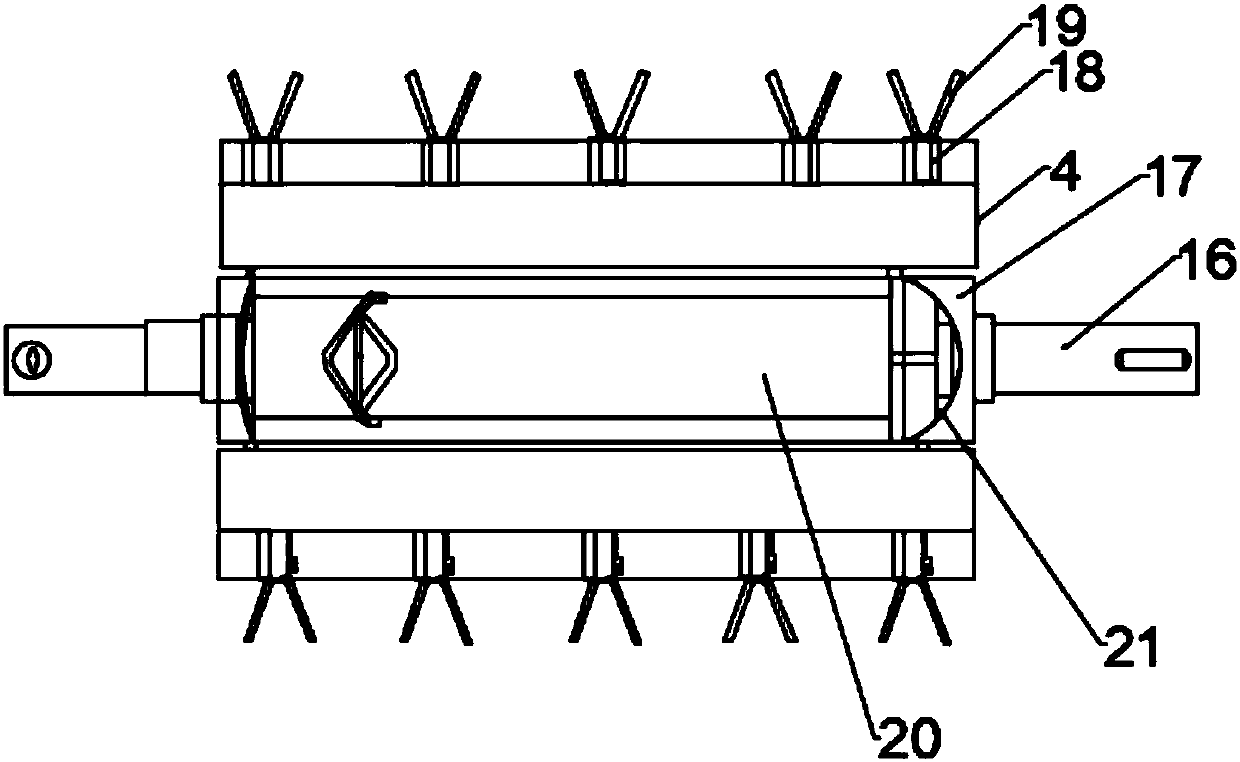

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a fertilizer mixing device used in fertilizer production, comprising a support frame 1 and a planetary stirring rotor 11, the upper surface of the support frame 1 is fixedly equipped with a storage tank 2, and the storage tank The upper surface of the 2 is provided with a conical feeding port 3, and the inner surface of the storage barrel 2 is fixedly equipped with a crushing barrel 4, and the lower end of the conical feeding port 2 is directly connected to the top entrance of the crushing barrel 4. connected, the lower end of the crushing barrel 4 is connected with the feeding pipe 5 through the O-ring 22, the lower end of the crushing barrel 4 adopts a conical structure to place the material on the grinding plate 12 through the feeding pipe 5, and utilizes The O-shaped sealing ring 22 seals the connection between the pulverizing barrel 4 and the feeding pipe 5 to prevent the fertilizer material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com