Novel volatile organic compounds (VOC) concentration treatment method

A treatment method and a new technology, applied in the field of new VOC concentration treatment, to achieve the effect of less movable components, strong work continuity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

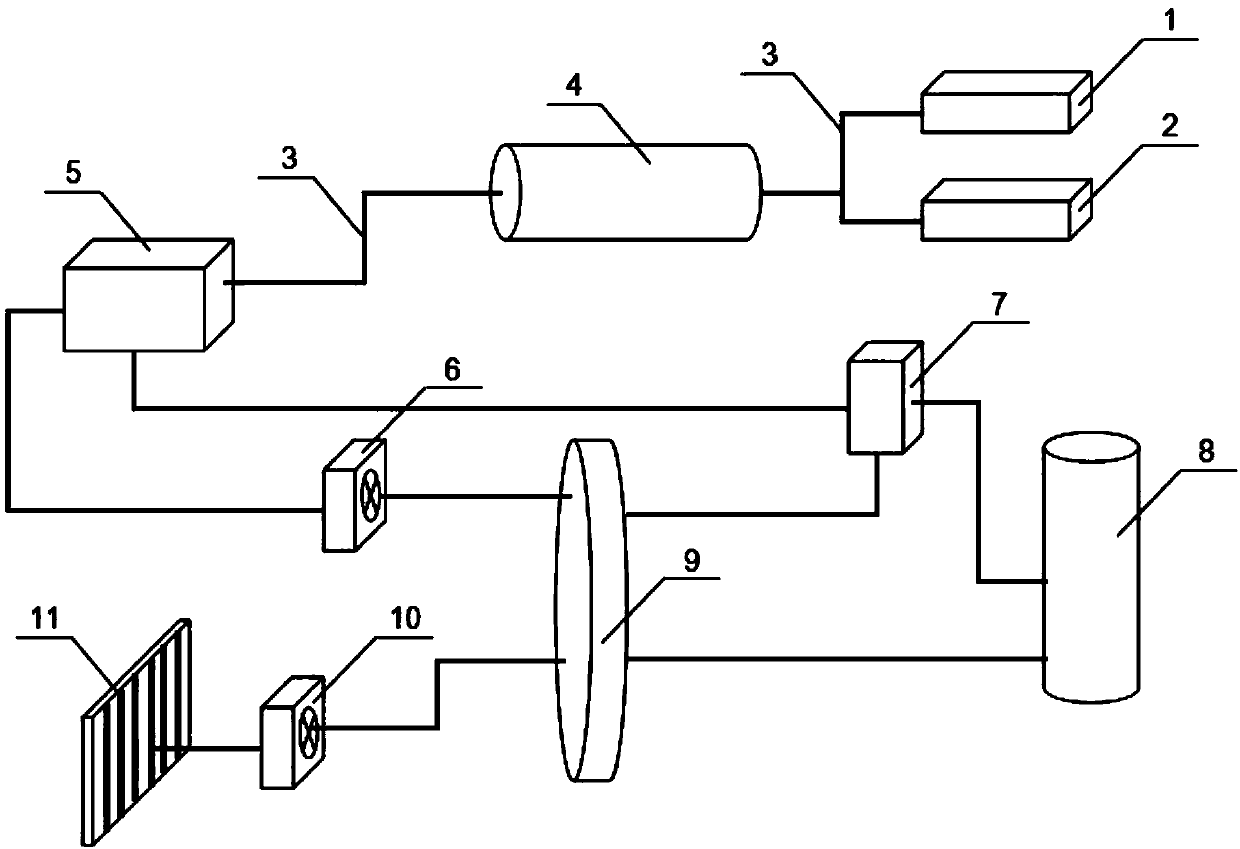

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] A novel VOC concentration treatment method of the present invention is characterized in that: comprising the following steps,

[0018] (1) To deal with VOC exhaust gas with a concentration of less than 800ppm and a temperature below 40°C with a large air volume. Under the action of the treatment fan 10, the VOC exhaust gas enters the VOC concentration runner 9 through the filter 11, and passes through the zeolite in the VOC concentration runner 9. The VOC waste gas is adsorbed, and the treated tail gas enters the chimney 8 through the pipeline 3 and is discharged into the atmosphere; the treated tail gas enters the chimney 8 under the action of the exhaust frequency conversion fan; the VOC concentration runner 9 rotates at a speed of 1-6 rpm;

[0019] (2) The VOC in the VOC concentrating runner 9 is concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com