Novel VOC concentration system

A concentration system and a new type of technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of lack of efficient and stable VOC concentration treatment system, and achieve low pressure loss, less movable components, and no adsorption loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

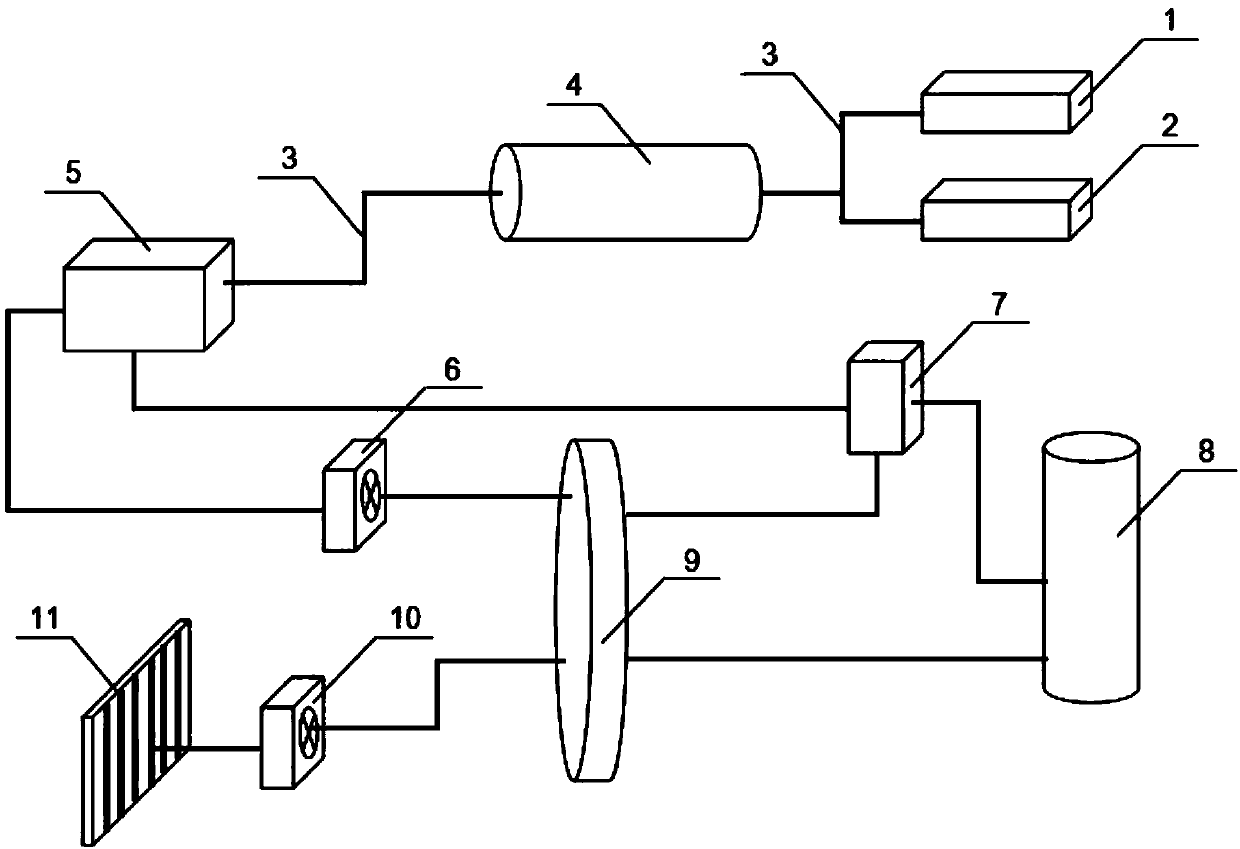

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] A novel VOC concentration system of the present invention is characterized in that it includes a compressed air machine 1, a combustion-supporting machine 2, a pipeline 3, a combustion device 4, a heat exchanger 5, a regeneration fan 6, a heat exchanger 7, a chimney 8, and a VOC concentration converter. Wheel 9, processing fan 10, filter 11; combustion device 4 is provided with several igniters, the right part of combustion device 4 is connected with compressed air machine 1 and combustion-supporting machine 2 respectively through separate pipeline 3, and the left part of combustion device 4 passes through pipeline 3 is connected to the heat exchanger 5; one way of the heat exchanger 5 is connected to the heat exchanger 7 and the chimney 8 through the pipeline 3, and the other way of the heat exchanger 5 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com