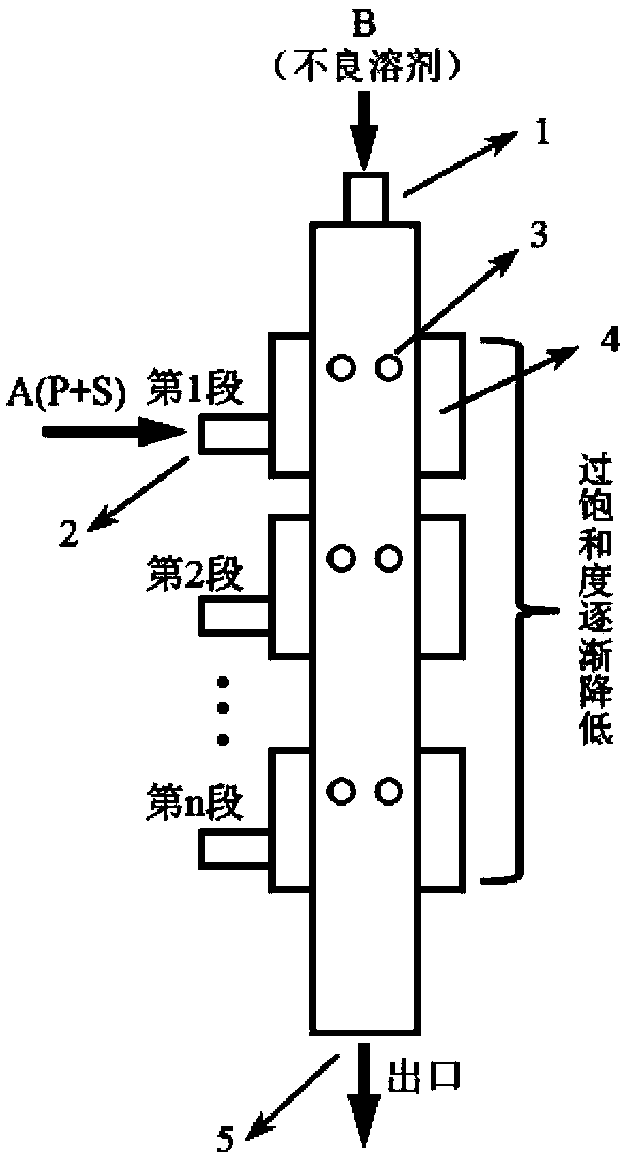

Multi-section feeding type anti-solvent spraying crystallizer and spraying crystallization method thereof

A tubular crystallizer and anti-solvent technology, applied in solution crystallization, alkali metal chloride, organic chemistry, etc., can solve the problems of slow crystallization process, wide particle size distribution, uneven supersaturation distribution, etc. The effect of small diameter, rapid nucleation, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

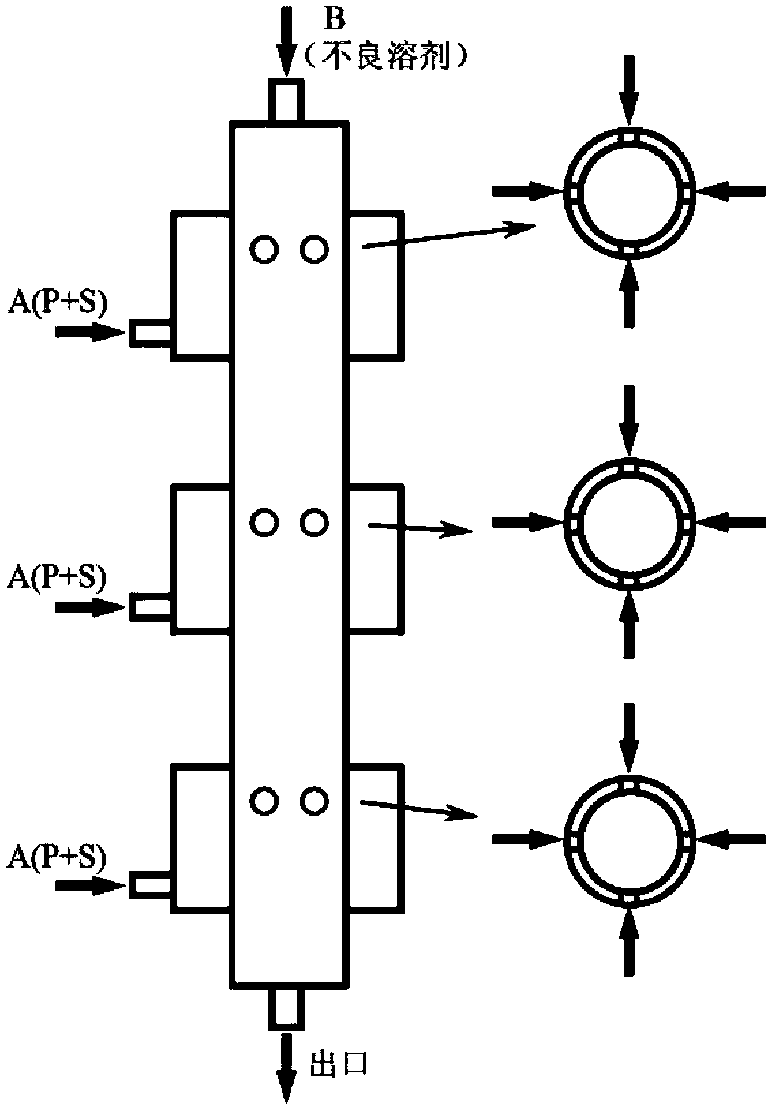

[0026] Sodium chloride crystal particles are prepared by using a jet crystallizer with double-stage feeding. The central tube of the jet crystallizer is a round tube with an inner diameter of 10mm. There are four tubes with a diameter of 2mm evenly distributed on the two tube walls at a distance of 50mm and 100mm from the entrance of the round tube. The small hole, the total length of the spray crystallizer tube is 300mm.

[0027] Ethanol is used as anti-solvent at normal temperature, and the flow rate is 500L / h, and it enters the spray crystallizer from the feed port of the central tube of the spray crystallizer. The sodium chloride aqueous solution fed into the first stage has a concentration of 200g / L. After entering the buffer chamber from the feed side hole of the first stage of the spray crystallizer, it is sprayed into the central circular pipe through the small hole, and the flow rate is 100L / h. The sodium chloride aqueous solution fed in the second stage has a concent...

Embodiment 2

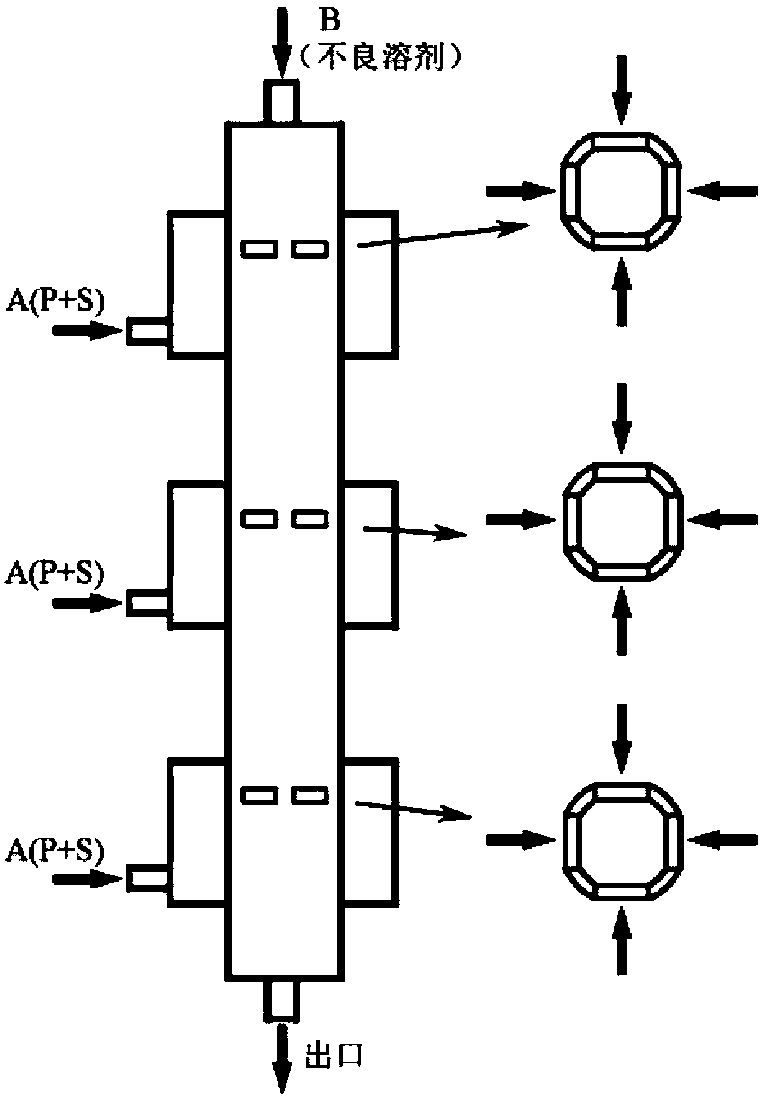

[0029] The spray crystallizer with three-stage feed is used to prepare urapidil crystal particles. The central tube of the spray crystallizer is a round tube with an inner diameter of 15mm, and there are two symmetrically distributed tube walls at 40mm, 80mm, and 120mm from the entrance of the round tube. A slit with a length of 4mm and a width of 2mm, the total length of the spray crystallizer tube is 350mm.

[0030] Petroleum ether is used as an anti-solvent at normal temperature, with a flow rate of 700L / h, and enters the jet crystallizer from the feed port of the central tube of the jet crystallizer. The urapidil chloroform solution concentration of the first stage feed is 250g / L, after entering the buffer chamber from the first stage feed side hole of the jet crystallizer, it is sprayed into the central circular pipe by the slit, and the flow rate is 100L / h. The urapidil chloroform solution concentration of the second stage feed is 300g / L, after entering the buffer chambe...

Embodiment 3

[0032] Hexanitrohexaazaisowurtzitane (CL-20) crystal particles were prepared by using a three-stage feeding jet crystallizer. The center tube of the jet crystallizer was a circular tube with an inner diameter of 20mm, and the distance from the entrance of the circular tube was 50mm, 100mm, and 150mm. There are 4 circular holes with a diameter of 3mm distributed symmetrically on the three pipe walls, and the total length of the spray crystallizer circular pipe is 450mm.

[0033]At room temperature, n-heptane is used as an anti-solvent with a flow rate of 700L / h, and it enters the jet crystallizer from the feed port of the central tube of the jet crystallizer. The concentration of CL-20 ethyl acetate solution fed into the first stage is 300g / L. After entering the buffer chamber from the feed side hole of the first stage of the jet crystallizer, it is sprayed into the central circular pipe through the small hole, and the flow rate is 100L / h. The concentration of the CL-20 ethyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com