System for automatically detecting airtightness of windows and doors of building and control method

An automatic detection, building door and window technology, applied in the use of liquid/vacuum for liquid tightness measurement, by detecting the appearance of fluid at the leak point, by measuring the fluid's rate of increase and deceleration, etc. It is difficult to ensure the accuracy, uneven distribution of wind speed, etc., to achieve the effect of good social practical value, reduce human intervention, and achieve automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

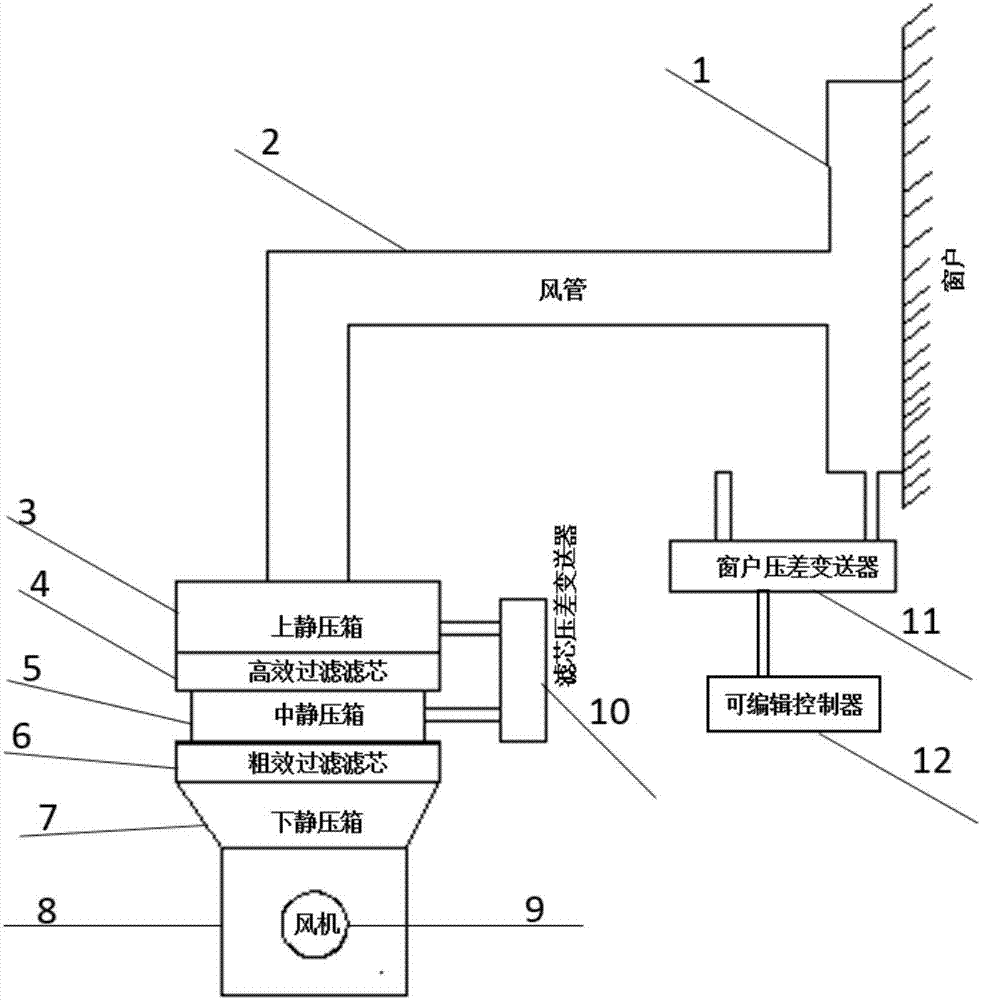

[0029] Such as figure 1 As shown, the door and window air tightness detection system mainly includes a sealing film 1, an air duct 2, an upper plenum box 3, a high-efficiency filter element 4, a middle plenum box 5, a coarse-effect filter element 6, a lower plenum box 7, Fan static pressure box 8, high pressure fan 9, filter core differential pressure transmitter 10, window differential pressure transmitter 11, editable controller 12. A high-pressure fan is housed in the fan static plenum, the air inlet of the fan static plenum communicates with the atmosphere, and the air outlet and the lower static plenum are connected by flanges; the coarse-effect filter element 6 is installed in the middle static plenum and Between the lower static pressure box; the high-efficiency filter element 4 is installed between the upper static pressure box 3 and the middle static pressure box 5, and the static pressure box and the filter element are connected by a flange, and a sealing strip is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com