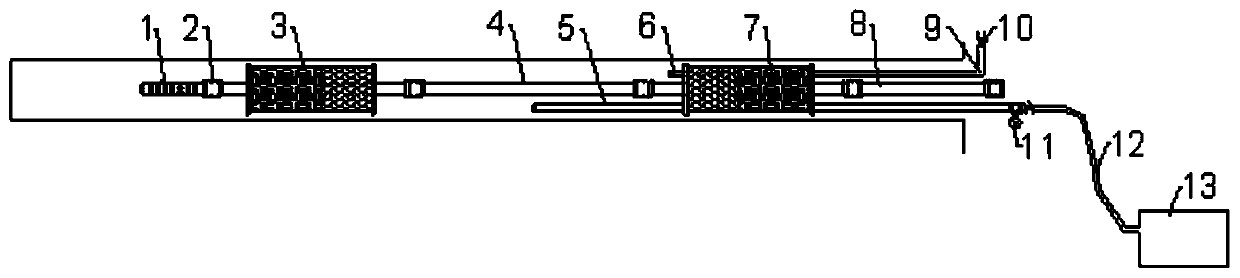

Automatic water absorption sealing-hole plugging device and method for near-horizontal coal seam gas extraction drill hole

A technology for coal seam gas extraction and drilling, which is used in gas discharge, safety devices, sealing/packing, etc., and can solve the problem that the grouting pressure is difficult to achieve, the strength of the polyurethane grouting plug is low, and the sealing effect is difficult to achieve an ideal state. and other problems, to achieve the effect of improving compactness, simple sealing operation, and ensuring the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

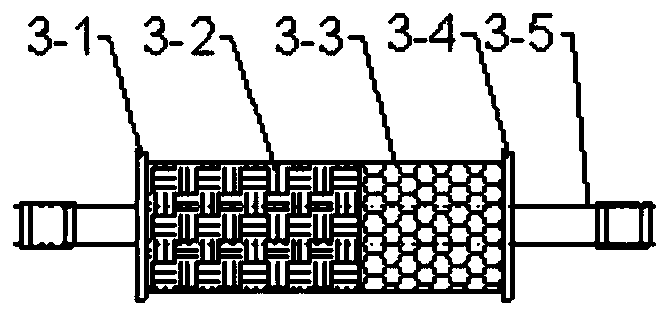

Method used

Image

Examples

Embodiment 2

[0050] This embodiment proposes a method for automatically absorbing water to plug and seal holes in gas drainage boreholes in near-horizontal coal seams, using the automatic water-absorbing and plugging and sealing devices for gas drainage in near-horizontal coal seams as proposed in Example 1, which is characterized in that it includes Follow the steps below:

[0051] Step 1. Drill holes in the coal seam to form boreholes. After the drilling construction is completed, use the compressed air device to blow away the accumulated water and cinders in the holes, and place the automatic water-absorbing and sealing device for the near-horizontal coal seam gas drainage drilling. inside the borehole;

[0052] Step 2. Inject expansive cement slurry into the grouting space through the grouting pipe 5. Initial injection, the injection speed of the expansive cement slurry is less than 10L / min, and the injection pressure is less than 0.2Mpa;

[0053] Step 3. The water-absorbent resin mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com