Single-action reciprocating hydraulic actuator

A hydraulic actuation and single-acting technology, applied in the hydraulic field, can solve problems such as crawling and system temperature rise, complex hydraulic system structure, and complex pipeline layout, and achieve convenient electrical layout, simplified hydraulic system structure, and valve block volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

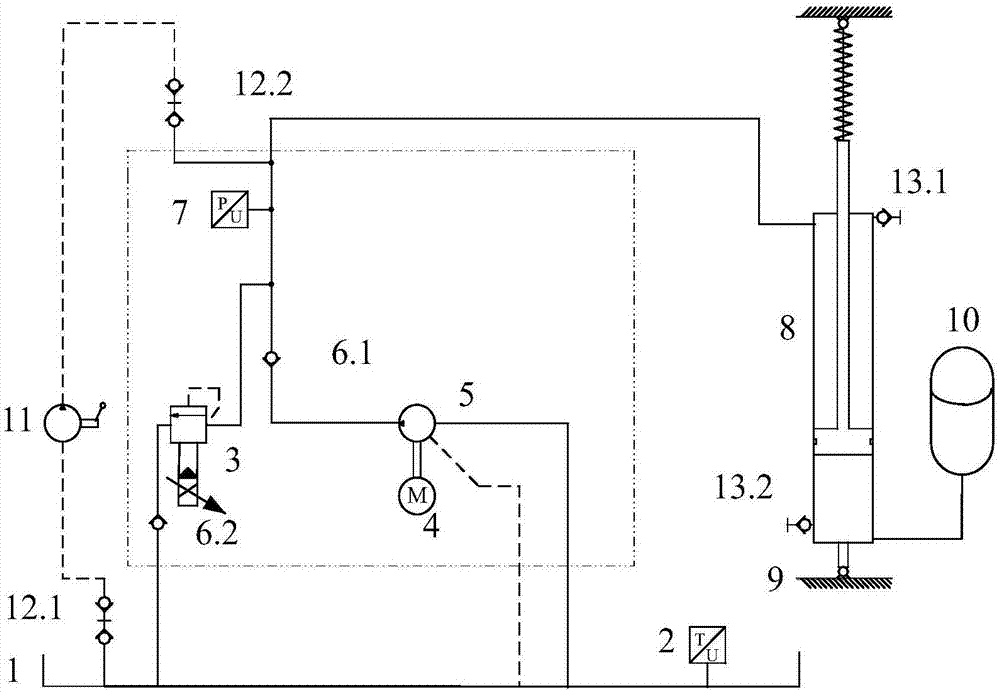

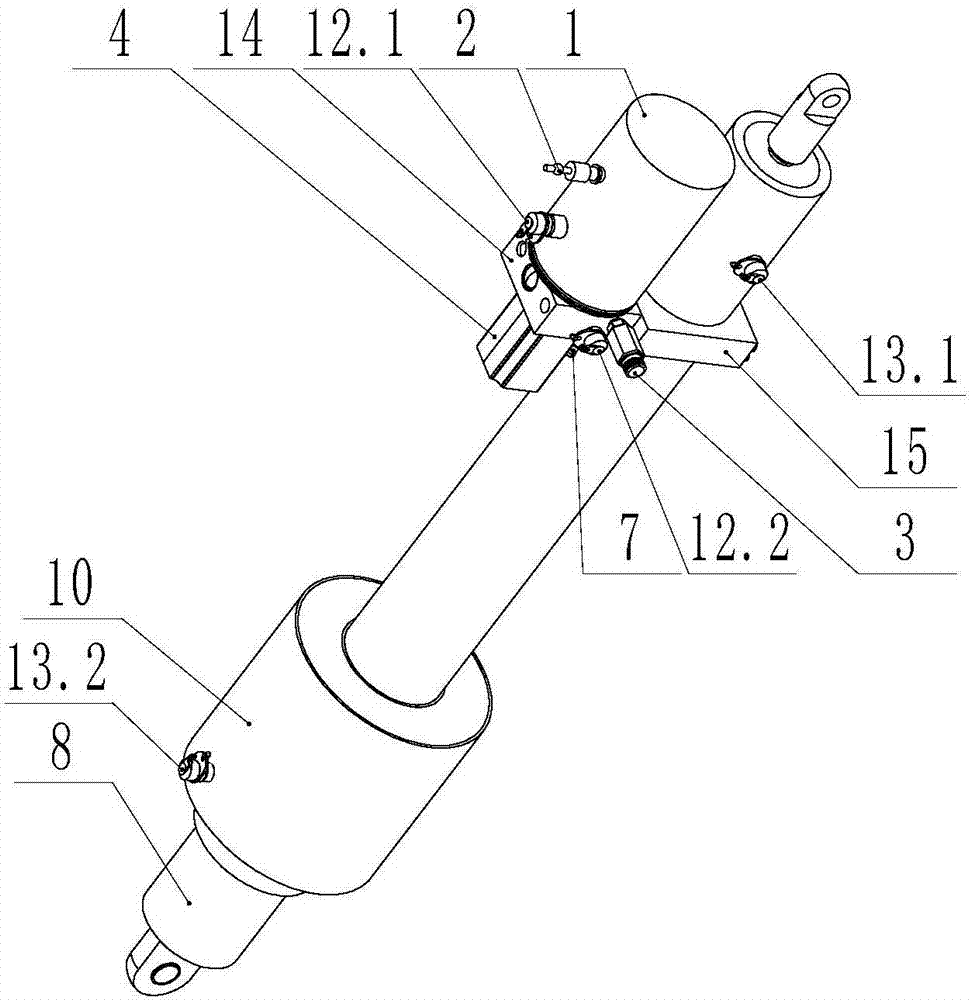

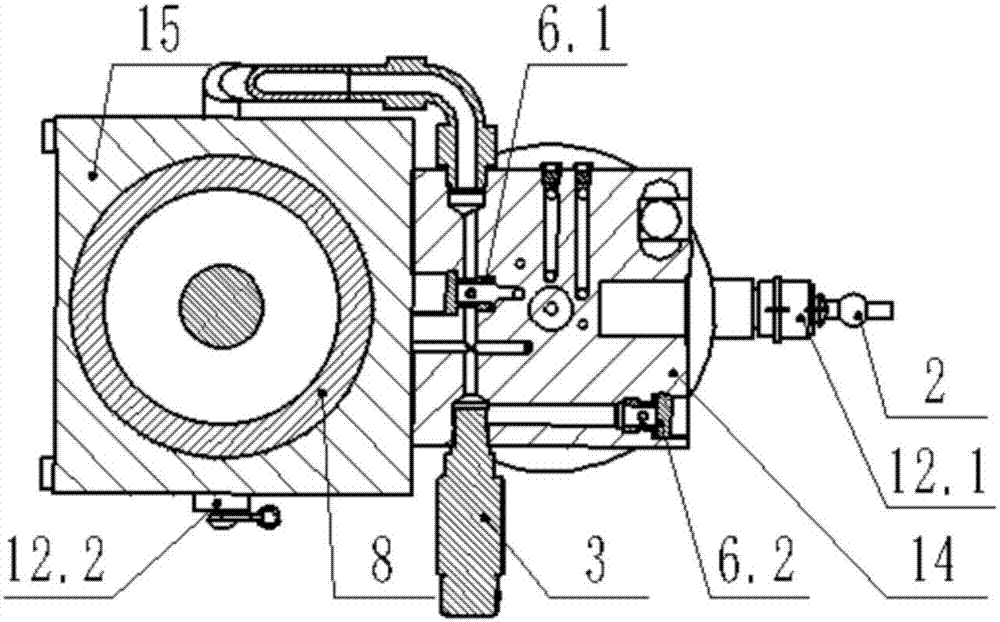

[0019] Such as figure 1 As shown, the hydraulic system of the present invention has: an oil tank 1, which is used as an oil storage device; a temperature sensor 2, which monitors the temperature of the hydraulic fluid; a proportional overflow valve 3, which is used to set different opening pressures, and realizes the pressure of the piston rod Safety pressure control when pulling back or extending, and back pressure protection when the piston rod is extended; motor 4, gear pump 5, gear pump 5 is driven by motor 4, and outputs high-pressure oil; check valve 1 6.1, check valve 2 6.2; The pressure sensor 7 is used to transmit the pressure of the rod cavity of the hydraulic cylinder in real time; the hydraulic cylinder 8, the accumulator 10, the accumulator is connected with the rodless cavity of the hydraulic cylinder, and the reciprocating movement of the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com