Device capable of eliminating electrostatic influence and used for electro-spinning direct writing

A technology of eliminating static electricity and electrospinning direct writing, which is applied in textiles and papermaking, filament/thread forming, fiber treatment, etc., to achieve the effect of eliminating static repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

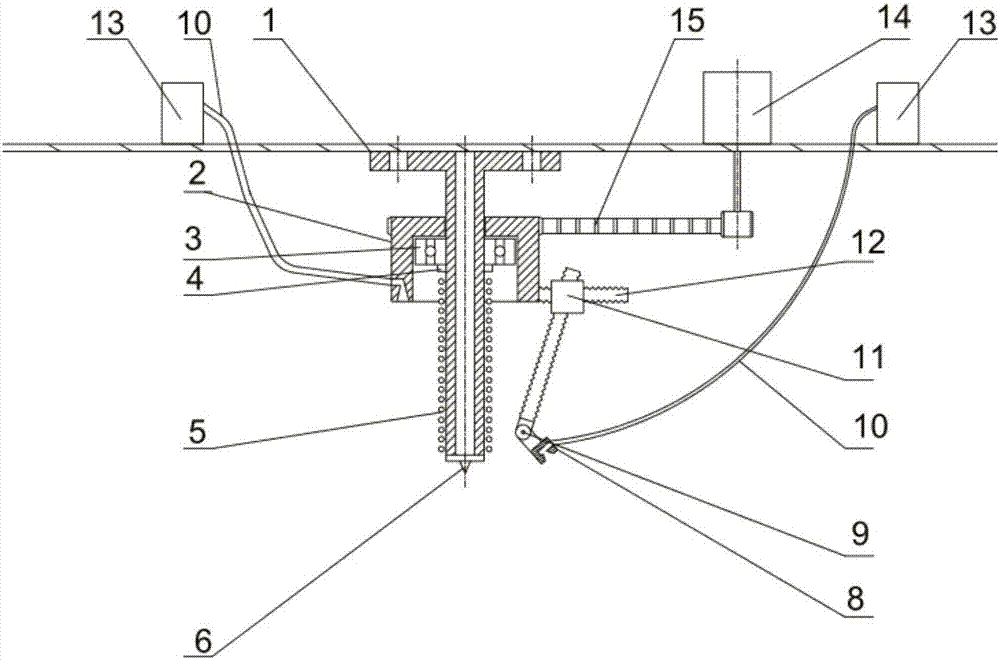

[0017] For the present invention, a device for electrospinning direct writing that can eliminate electrostatic influence, such as figure 1 and figure 2 As shown, it mainly includes the main channel 1, the customized gear plate 2, the bearing 3, the spring buckle 4, the heater 5, the dispensing nozzle 6, the three-dimensional motion platform 7, the ion wind nozzle 8, the rotation key 9, and the plastic hose 10 , connector 11, rack 12, ion generator 13, synchronous motor 14, synchronous belt 15, electrostatic generator and electrode plate. The electrostatic generator and electrode plates are not shown in the figure. The main channel 1 is located above the three-dimensional motion platform 7, the main channel 1 is fixed on the frame, the lower end of the main channel 1 is a dispensing nozzle 6, the outer wall of the main channel 1 is covered with a heater 5, and the upper end of the main channel 1 outer wall passes through the bearing 3 and the spring buckle 4 are supported wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com