Cleaning solution for removing calcium carbonate scale and preparation method and application of cleaning solution

A cleaning solution and clear water technology, applied in the field of chemical descaling, can solve the problems of difficult biodegradation, low scale dissolution efficiency, harmful to human health, etc., achieve good scale inhibition effect, slow down scaling speed, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

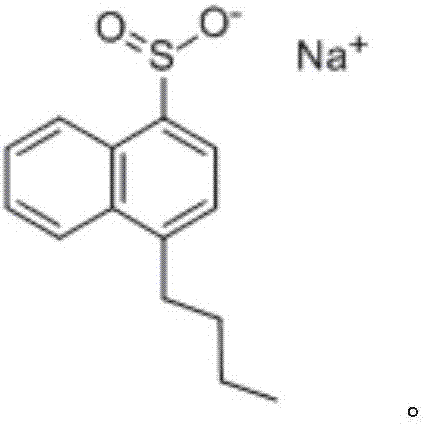

[0039] The present embodiment provides a cleaning solution for removing calcium carbonate scale, the cleaning solution comprises the following components in mass percentage: 3% of 2-hydroxypropane-1,2,3-tricarboxylic acid, diethyltriamine 10% of pentaacetic acid, 2% of osmotic cosolvent, 0.05% of oleic acid hydroxyethyl imidazoline, the balance is water, and the pH value of the cleaning solution is 6.5. Among them, the penetration cosolvent used in Example 1 can be prepared by the following method: put 10kg of polydimethylsiloxane, 150kg of glycerol and 250kg of clear water in a 1000L enamel reaction kettle, heat to 30°C, and stir 20min, then add 1.2kg sodium butylnaphthalene sulfonate, 50kg sodium hexametaphosphate and 200kg clear water, then reduce the temperature of the reactor to 15°C, and stir for 30min under constant temperature conditions to obtain the osmotic cosolvent used in Example 1 .

[0040] The cleaning solution provided in this embodiment is prepared by the fo...

Embodiment 2

[0043] The present embodiment provides a cleaning solution for removing calcium carbonate scale, the cleaning solution comprises the following components in mass percentage: 2-hydroxypropane-1,2,3-tricarboxylic acid 5%, diethyltriamine 15% of pentaacetic acid, 3% of osmotic cosolvent, 0.08% of oleic acid hydroxyethyl imidazoline, the balance is water, and the pH value of the cleaning solution is 6.2. Wherein, the penetration co-solvent used in Example 2 can be prepared by the following method: 12kg of polydimethylsiloxane, 160kg of glycerin and 240kg of clear water are placed in a 1000L enamel reaction kettle, heated to 35°C, and stirred 25min, then add 1.1kg sodium butylnaphthalenesulfonate, 55kg sodium hexametaphosphate and 220kg clear water, then reduce the temperature of the reactor to 18°C, and stir for 35min under constant temperature conditions to obtain the osmotic cosolvent used in Example 2 .

[0044] The cleaning solution provided in this embodiment is prepared by ...

Embodiment 3

[0047] The present embodiment provides a cleaning solution for removing calcium carbonate scale, the cleaning solution includes the following components in mass percentage: 6% of 2,3-dihydroxysuccinic acid, 20% of hydroxyethyl ethylenediamine triacetic acid , 5% permeation aid solvent, 0.1% mercaptobenzothiazole, the balance is water, and the pH value of the cleaning solution is 5.8. Among them, the permeation co-solvent used in Example 3 can be prepared by the following method: put 10kg of polyoxypropylene glyceryl ether, 170kg of lauryl alcohol and 250kg of clear water in a 1000L enamel reaction kettle, heat to 40°C, and stir for 30min. Then add 1.3kg of sodium butylnaphthalene sulfonate, 50kg of sodium hexametaphosphate and 200kg of clear water, then lower the temperature of the reactor to 20°C, and stir for 40min at a constant temperature to obtain the osmotic cosolvent used in Example 3.

[0048] The cleaning solution provided in this embodiment is prepared by the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com