Rubber composition used for automobile suspension bushing

A technology of rubber composition and automobile suspension, applied in the field of rubber, can solve the problem of not considering the bonding performance of products, and achieve the effects of good bonding performance, good mechanical performance and good heat resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

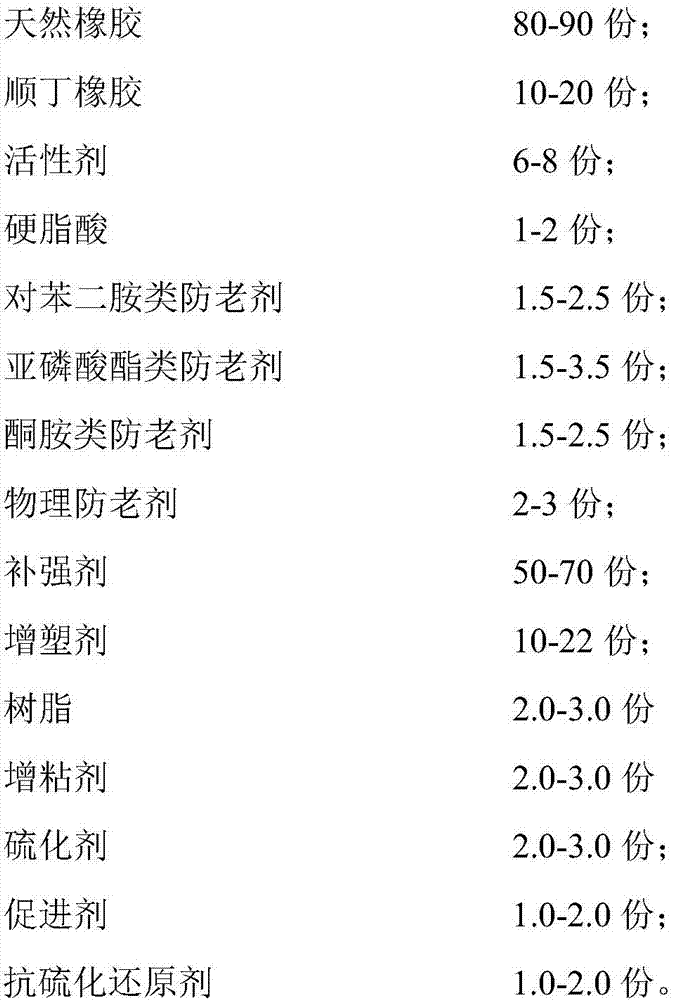

[0032] A rubber composition for an automobile suspension bushing, comprising the following components in parts by weight:

[0033]

[0034] The preparation of above-mentioned composition can adopt internal mixer mixing, and its steps are as follows:

[0035] (1) Active agent, stearic acid, p-phenylenediamine antioxidant, phosphite ester antioxidant, ketamine antioxidant, physical antioxidant, resin, tackifier and anti-vulcanization reducing agent are grouped in parts by weight Allocated as a fine material for use;

[0036] (2) Raise the temperature of the internal mixer to 90-110°C, put the plasticized Vietnam SVR-3L and butadiene rubber into the mixing chamber for 60 seconds, and then lift the top bolt to add the prepared in step (1) For fine materials, add reinforcing agent and plasticizer after 60s, lift the top bolt to clean the machine and the carbon black on the top bolt after 180s, put down the top bolt and continue banburying for 60s, then discharge glue and roll o...

Embodiment 2

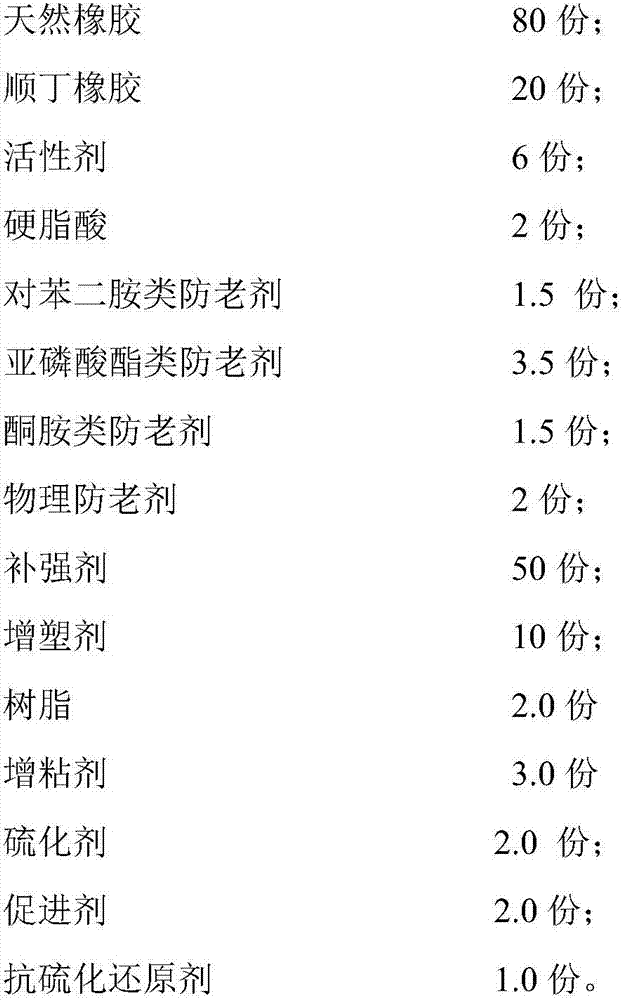

[0038] A rubber composition for an automobile suspension bushing, comprising the following components in parts by weight:

[0039]

[0040] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

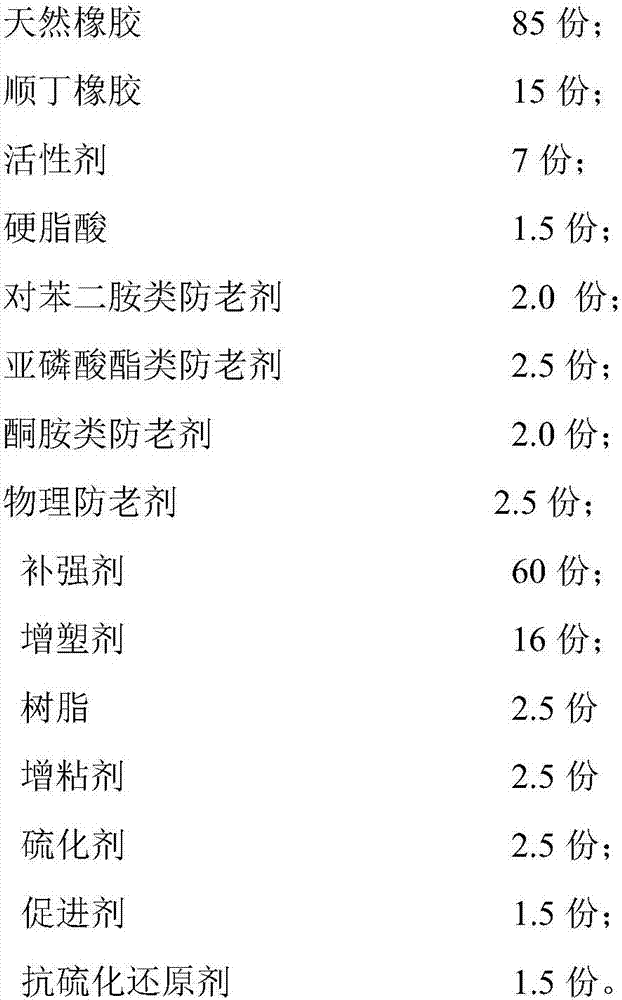

[0042] A rubber composition for an automobile suspension bushing, comprising the following components in parts by weight:

[0043]

[0044] The preparation method of this embodiment is the same as that of Example 1.

[0045] Embodiment 1-3 is carried out rubber material test respectively, and gained data is as follows:

[0046]

[0047] The suspension bush made of the rubber composition in Examples 1-3 was subjected to a dynamic fatigue test. The test data are as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com