Large spacing deck web crossbeam and groove-type longitudinal bulkhead connecting structure

A technology for connecting structures and strong beams, applied in the direction of hull deck, hull parts, hull, etc., can solve the problems of increasing structural weight and loss of cabin capacity, and achieves the effect of reducing structural weight, reducing quantity, and reducing cabin capacity loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

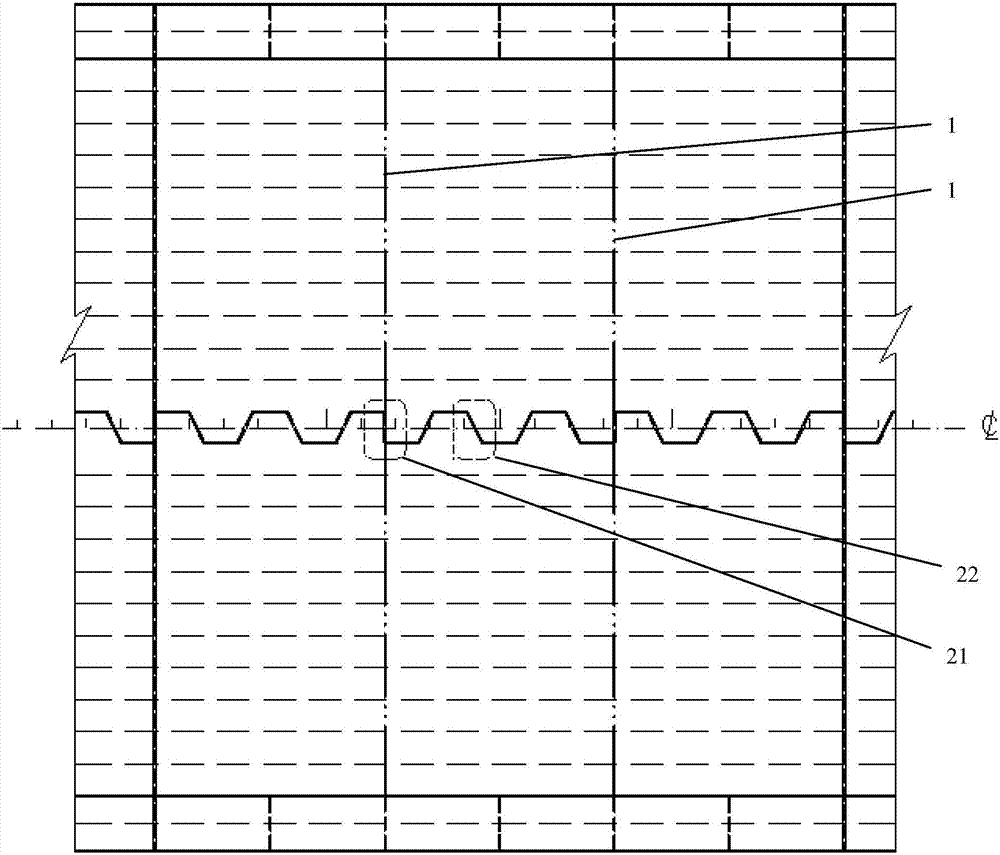

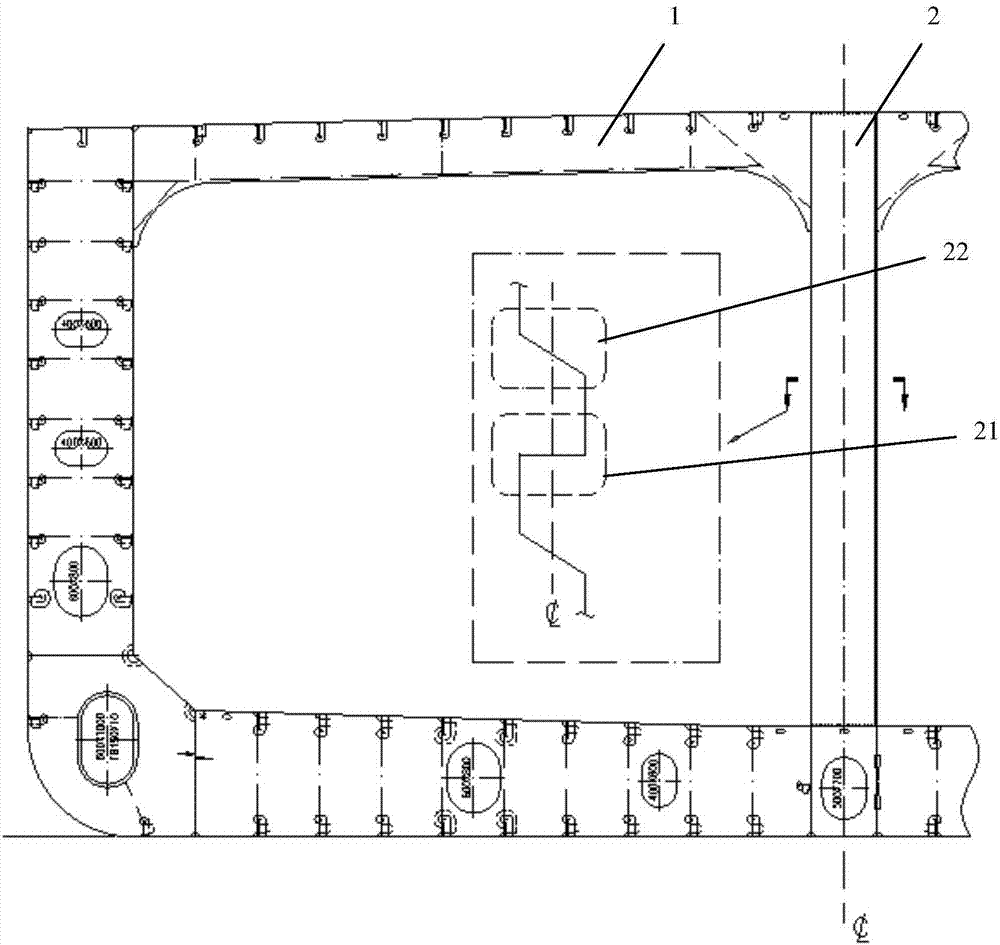

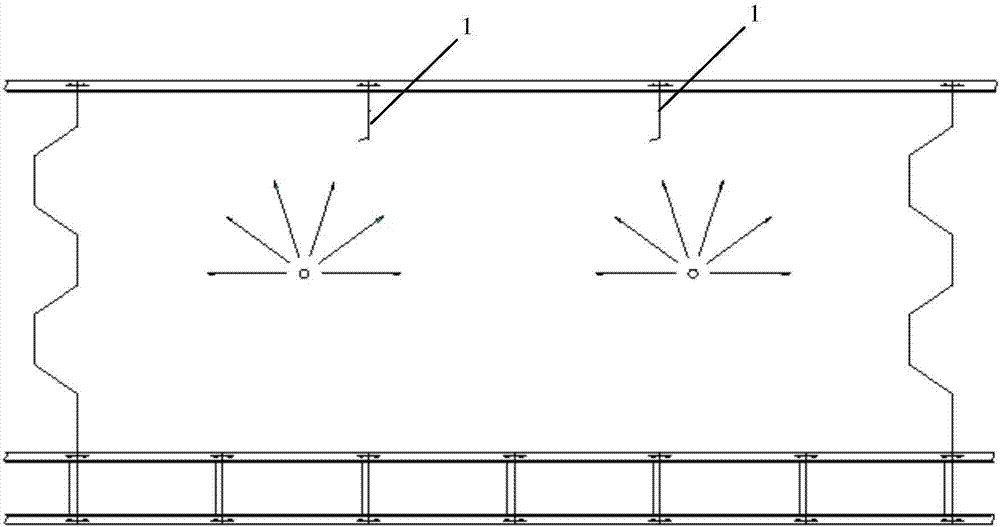

[0028] In further embodiments of the present invention, see Figure 1 to Figure 3 As shown, the end of the deck beam 1 is arc-shaped.

[0029] In a further embodiment of the present invention, the end of the deck web 1 is aligned with the web of the right-angle groove 21 and welded. The end of the deck beam 1 is enlarged by a circular arc, and welded in alignment with the web of the right-angle groove 21, which ensures the effective connection between the deck beam 1 and the trough bulkhead 2, avoids the setting of deck longitudinal pipes, and reduces the loss of cabin capacity and reduce structural weight.

[0030] In a further embodiment of the present invention, the numbers and relative distances of the deck web 1 , right-angled slots 21 and oblique-angled slots 22 can be changed accordingly according to the length of the cargo hold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com