Continuous flow microfluidic system

A microfluidic chip, continuous technology, used in fluid mixers, instruments, nanoparticle analysis, etc., can solve the problems of expensive, expensive, and increased batch size of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

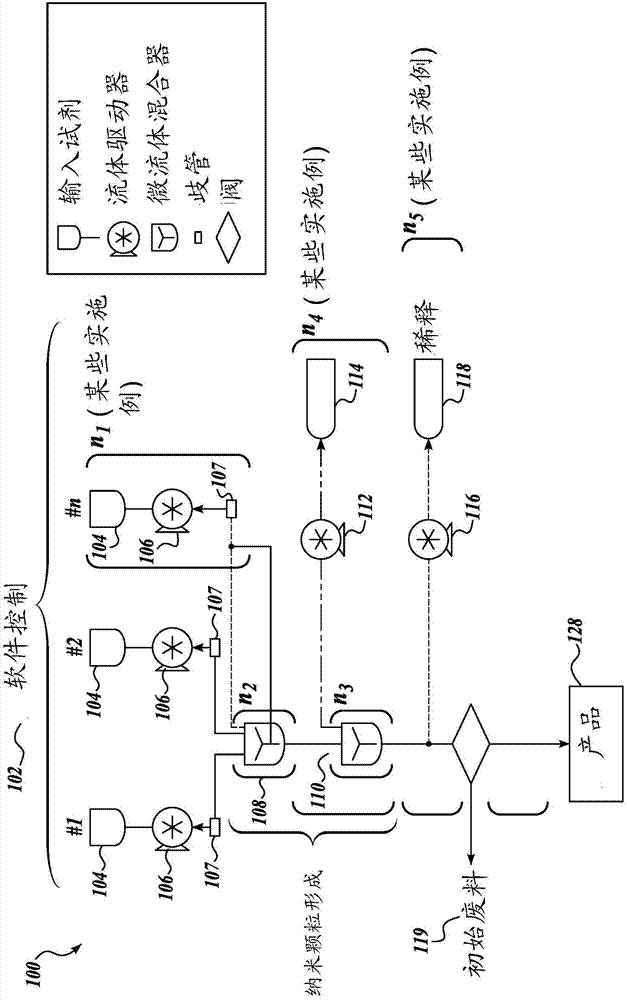

[0346] Example 1: Use of four single microfluidic mixer devices arranged in parallel utilizing a manifold, or in a single device siRNA-lipid nanoparticles (siRNA-LNP) fabricated by four microfluidic mixers arranged in parallel.

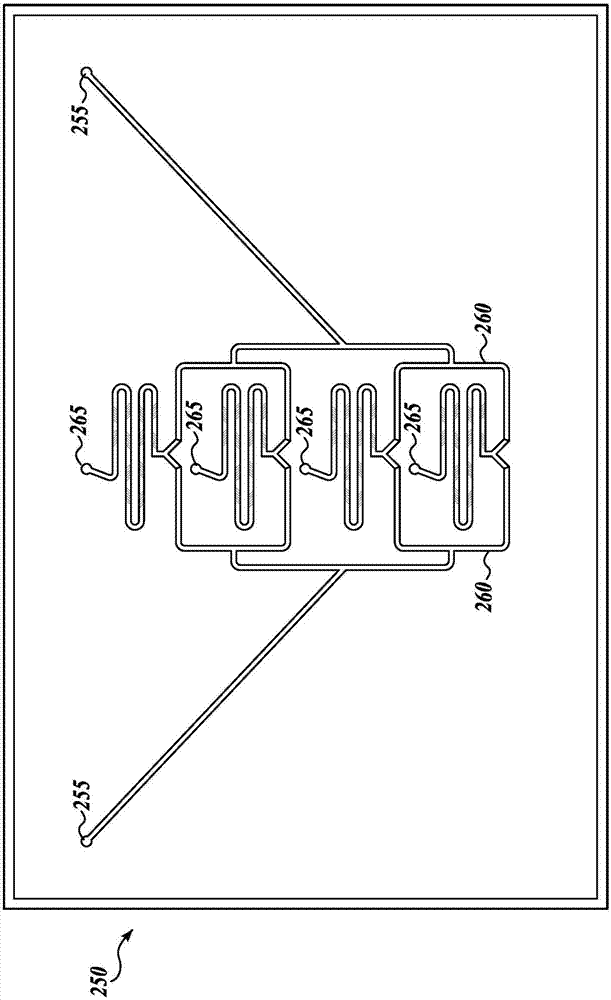

[0347] In this example, siRNA-LNP produced using four single microfluidic mixer devices in parallel utilizing a manifold was compared to siRNA-LNP produced using four microfluidic mixers arranged in parallel in a single device ( image 3 )Compare. The purpose of this example is to demonstrate that there is a method of arranging the opening-means and closing-means of a microfluidic mixer. The fluid-driven pumps were operated under the same process conditions, with the same nanoparticle-forming material, and tested for each placement method. Figure 4 The results in show that similar siRNA-LNPs were produced using both placement methods and that siRNA-LNPs were not affected by the placement method. This example significantly demonstrates the possi...

example 2

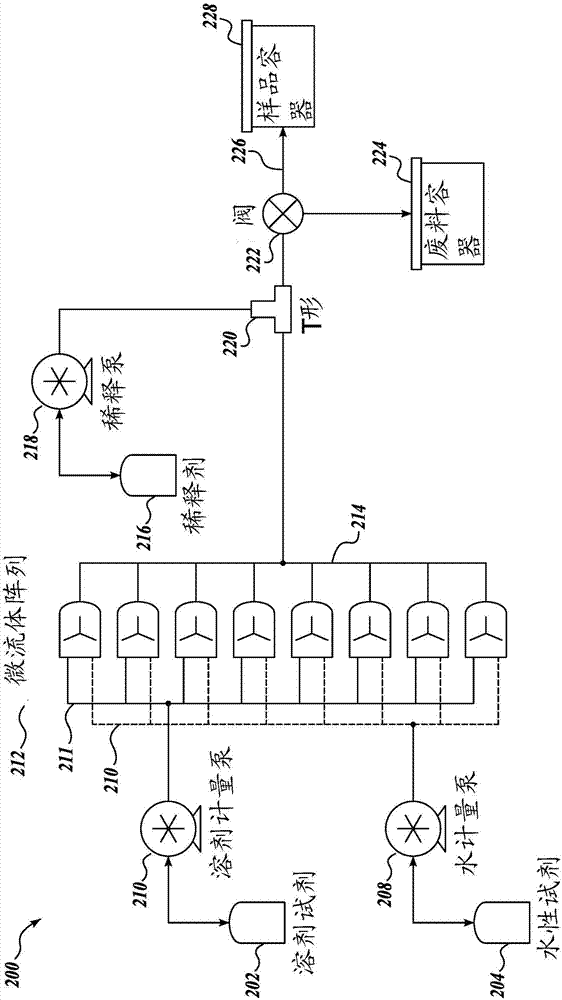

[0351] Example 2: siRNA-Lipid Nanoparticles Fabricated Using Eight Single Microfluidic Mixer Devices Arranged in Parallel Using a Manifold Rice Granules (siRNA-LNP)

[0352] In this example, a volume of 520 mL of siRNA-LNP was generated using eight single microfluidic mixer devices arranged in parallel with an external manifold. Each mixer in the array is identical so that the process conditions for forming siRNA-LNPs in each mixer are the same. The purpose of this experiment was to demonstrate the effect of a large number of parallel mixers on the size and quality of siRNA-LNPs. This example notably demonstrates the successful utilization of a large number of microfluidic mixers used in parallel in the same system to generate high-volume batches of siRNA-LNPs using the exemplary systems disclosed herein.

[0353] Figure 5 Particle size (nm) and polydispersity index (PDI) of representative siRNA-lipid nanoparticles (siRNA-LNPs) are shown as a function of preparation volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrodynamic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com