Plate type ceramic oxygen sensor

An oxygen sensor, a flat-plate technology, applied in the field of oxygen sensors, can solve problems such as warping, and achieve the effect of avoiding sintering shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

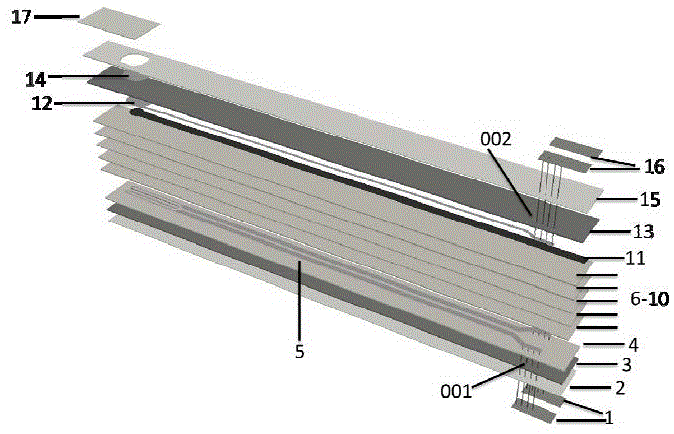

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The same reference numerals are assigned to the same or corresponding components in the respective drawings.

[0038] figure 1 It is a schematic diagram showing the structure of a flat ceramic oxygen sensor according to an embodiment of the present invention. in the figure 1 In the illustrated embodiment, for the convenience of expression, the stacking direction is also referred to as the up-down direction.

[0039] Such as figure 1 As shown, the ceramic oxygen sensor S according to the present invention is electrode pin 1, alumina insulating layer 2, zirconia symmetrical layer 3, alumina substrate layer 4, heater 5, alumina substrate layer 6- 10. Reference gas channel 11, inner sensitive electrode 12, zirconia functional layer 13, outer sensitive electrode 14, aluminum oxide insulating layer 15, electrode pin 16 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com