Container damage detection equipment and method based on 3D imaging

A technology for damage detection and detection equipment, which is used in measurement devices, optical testing of flaws/defects, and material analysis by optical means. The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention needs to build a channel suitable for container vehicles to pass through, and install 3D cameras and lasers on the top, left side, right side, front end and rear end of the channel respectively, and respectively monitor the container top, left side, right side, The front and rear container surfaces are scanned to obtain surface texture information, and sensors are installed on the left and right sides of the channel to trigger 3D cameras and laser scanning.

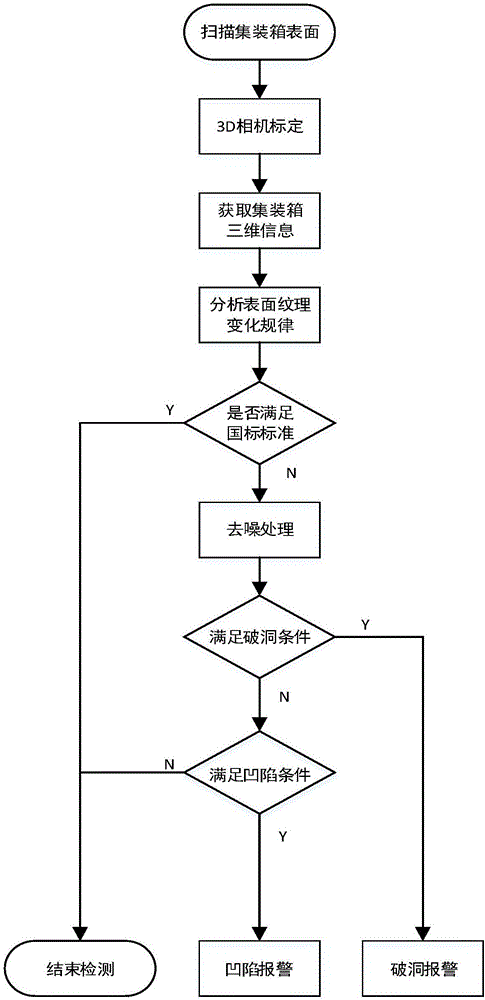

[0036] Such as figure 1 Shown, the realization method of the present invention is as follows:

[0037] 1. Laser Triangulation

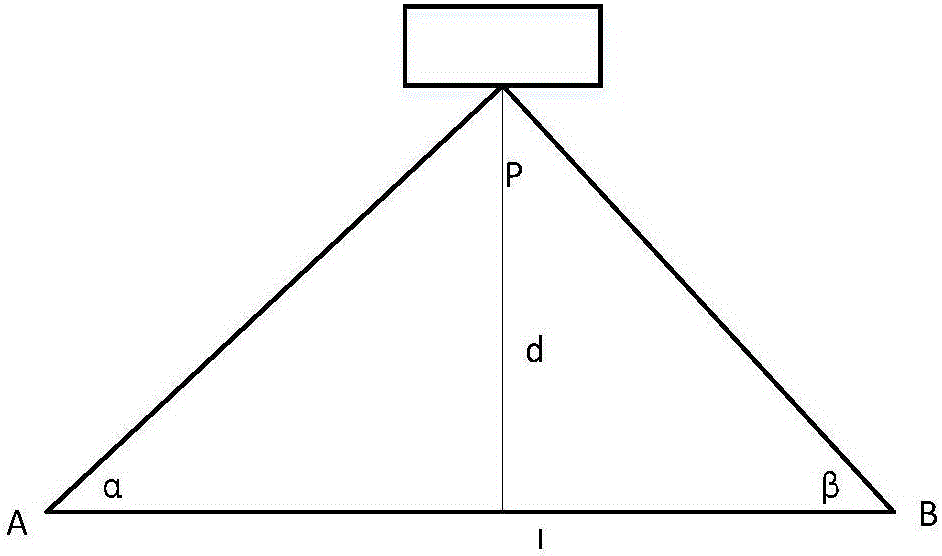

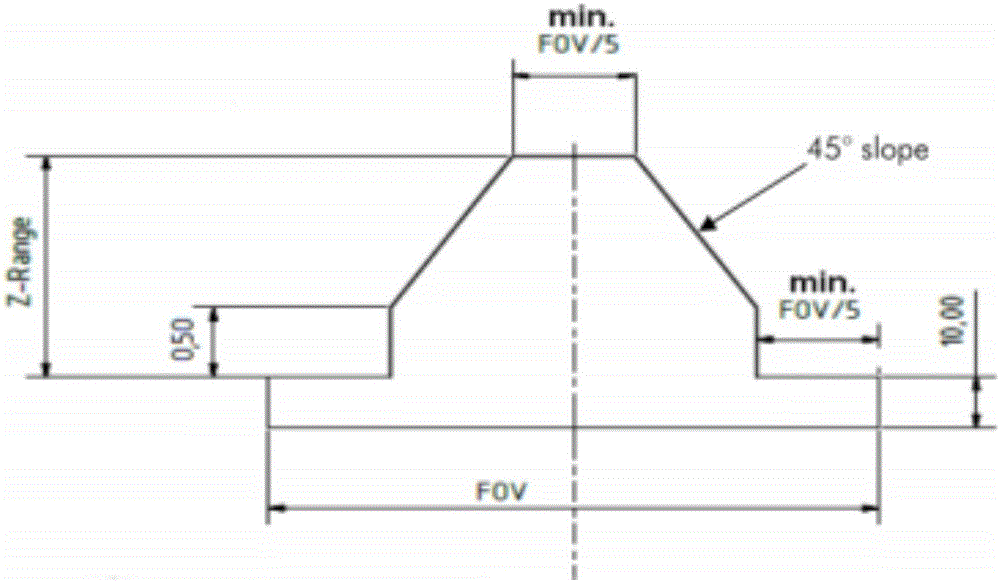

[0038] 3D scanning is mainly that the laser shoots the laser to the surface of the measured object through the lens, and the laser reflected by the object is received by the camera. According to different distances, the camera can "see" this light spot at different angles. Based on this angle and the known distance between the laser and the camera, the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com