Fireproof plate for tunnel and mounting structure and construction method thereof

A technology for installing structures and fireproof boards, which is applied in tunnels, tunnel linings, and fire prevention. It can solve problems such as unsatisfactory fireproofing and heat insulation effects, and achieve improved fireproofing safety levels, slowing down the heating time, and good toughness and bending resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A fire-proof board for a tunnel, including a top fire-proof board and a side-wall fire-proof board; the raw material composition of the top board contains at least the following substances in mass percentages: wood 3.5-5%; cement bag 3-5.5%; quartz powder 32-5% 45%; cement 22-32%; calcium hydroxide 10-20%; aluminum hydroxide 3-5%; bentonite 0.5-1%;

[0030] The raw material composition of the side wall fireproof board contains at least the following substances in mass percentage: 4-5.5% of wood; 2-3.5% of cement bag; 40-55% of quartz powder; 30-45% of cement; 2-4% of aluminum hydroxide ; Bentonite 0.6 ~ 1.2%.

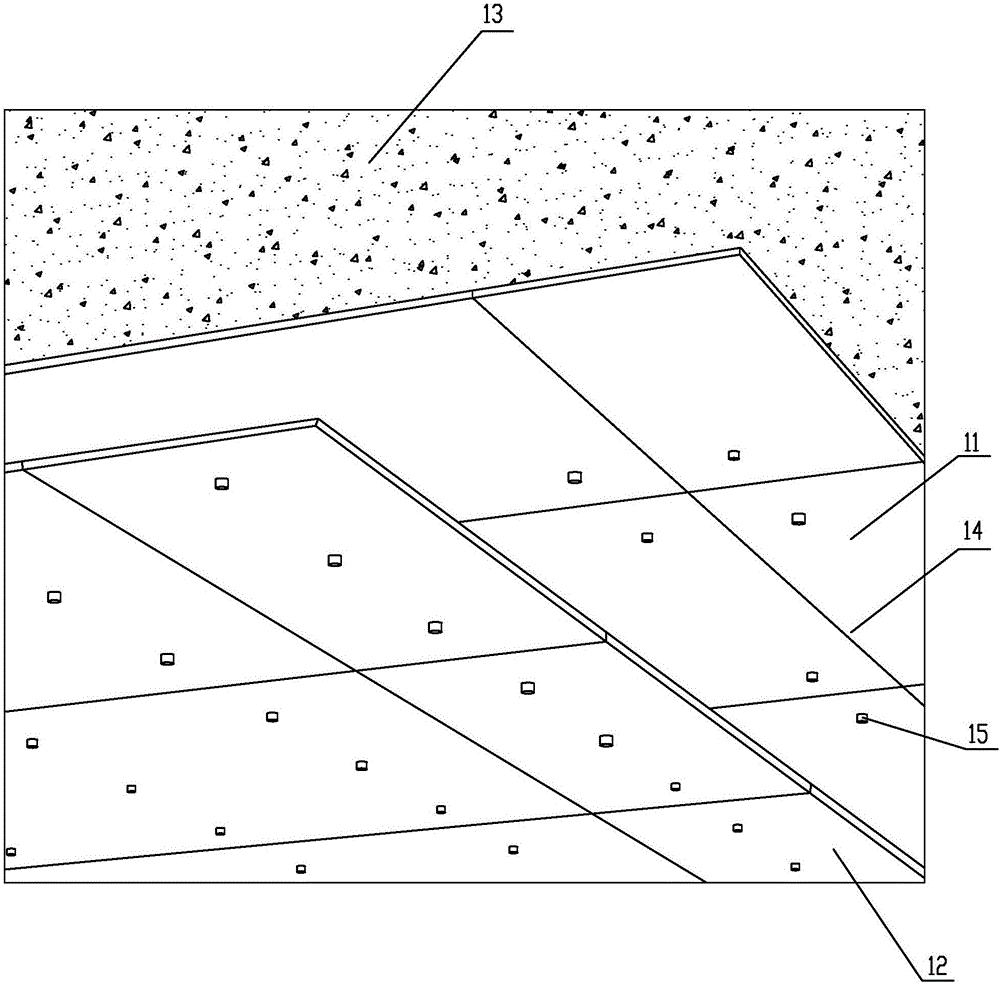

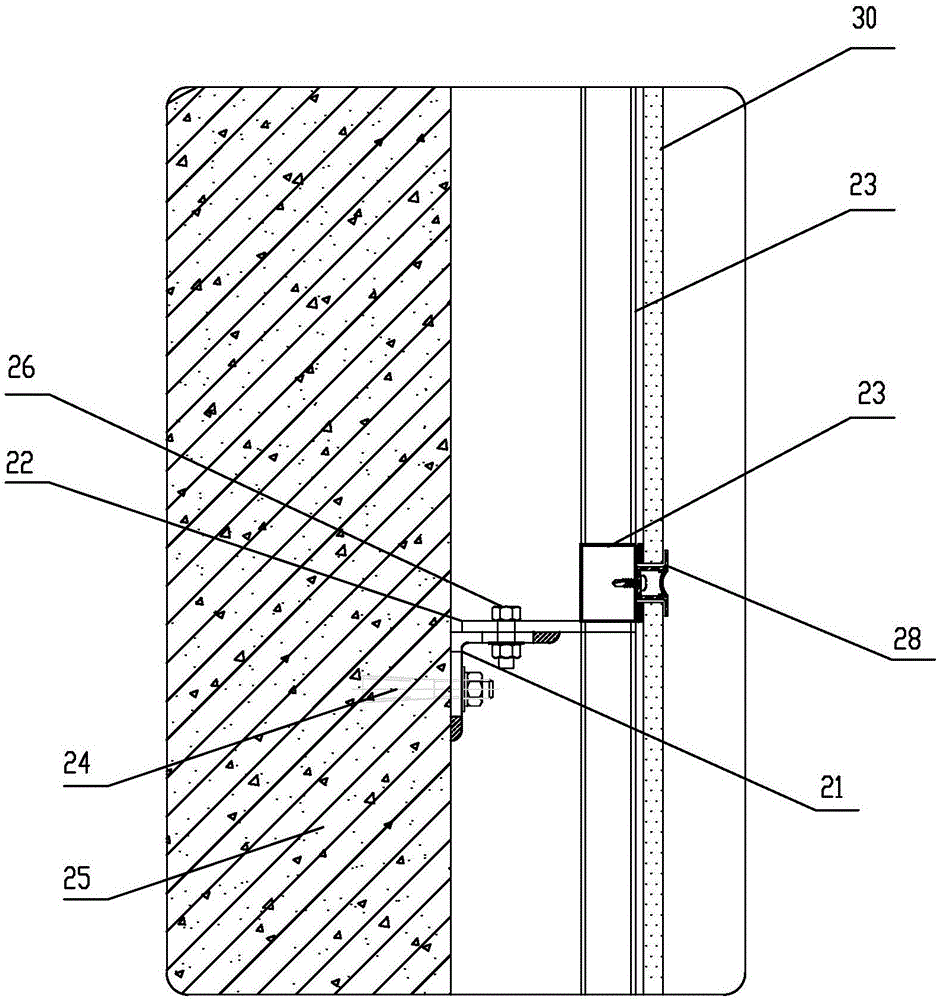

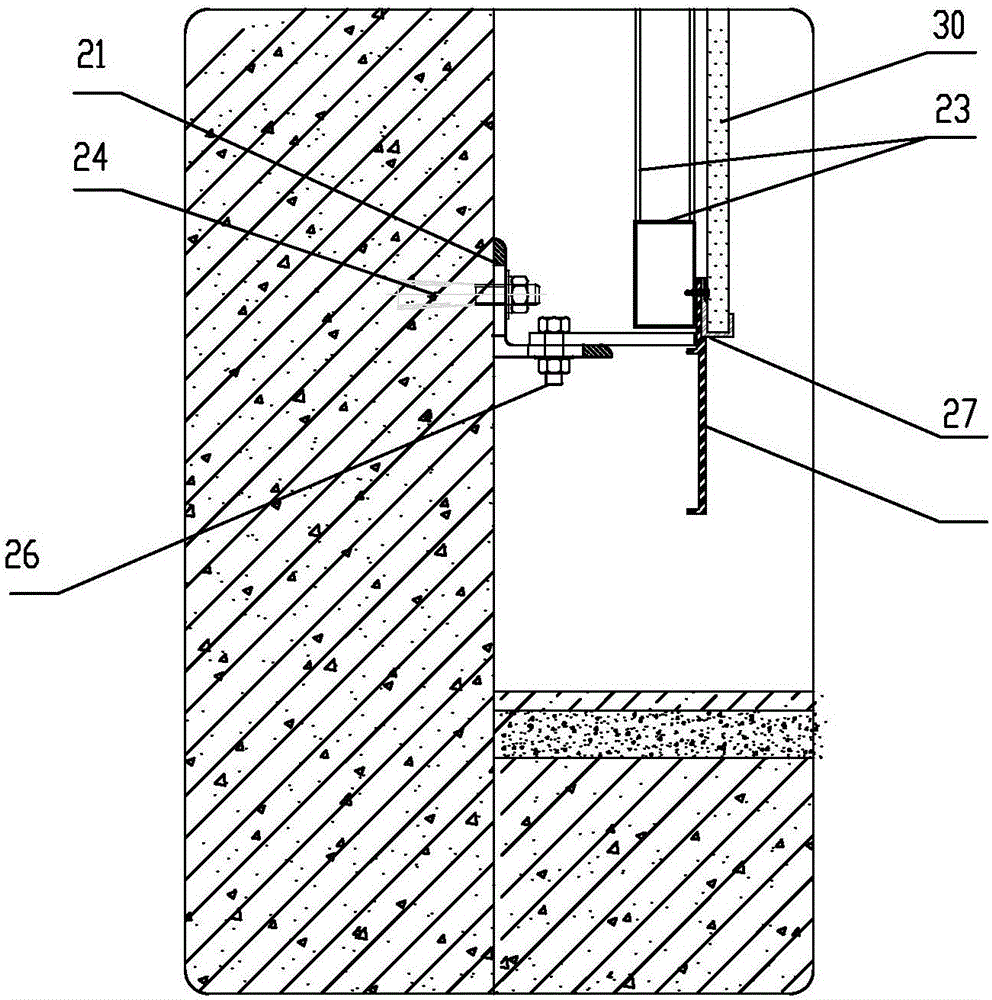

[0031] refer to Figure 1 to Figure 4 As shown, a fireproof board installation structure for tunnels includes a top fireproof board and side wall fireproof boards; the top fireproof board includes upper and lower fireproof boards 11 and 12, and the upper and lower fireproof boards 11 and 12 are staggered from each other ;

[0032] The installation structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com