Liquid detergent composition as well as preparation method and application thereof

A technology for liquid detergents and compositions, applied in the directions of detergent compositions, surface active detergent compositions, detergent compositions, fragrances, etc., to reduce scale deposition, improve scale resistance and oil removal rate, and achieve excellent scale resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] A method for preparing a liquid detergent composition, comprising the steps of:

[0094] 1) Put water into the batching pot first;

[0095] 2) Under stirring, slowly add the thickener, and after fully dispersed, adjust the pH to 5-9;

[0096] 3) Add component A, component B, and surfactant in sequence, and stir evenly;

[0097] 4) Put the essence and enzyme preparation into the batching pot and stir evenly;

[0098] 5) Add other additives into the batching pot and stir evenly;

[0099] 6) Pass the inspection and pack.

[0100] 250ppm hard water was used in the experiment to prepare according to the method of GB 9985-2000 B1.2.

[0101] Determination of anti-scaling performance:

[0102] Measuring principle: Use an electric heating rod to heat the scaling of different sample products in hard water.

[0103] Into the beaker, add 1.0L 250ppm hard water, and 8g sample, stir to dissolve, put into the electric heating rod, turn on the electricity to heat. When the wate...

Embodiment

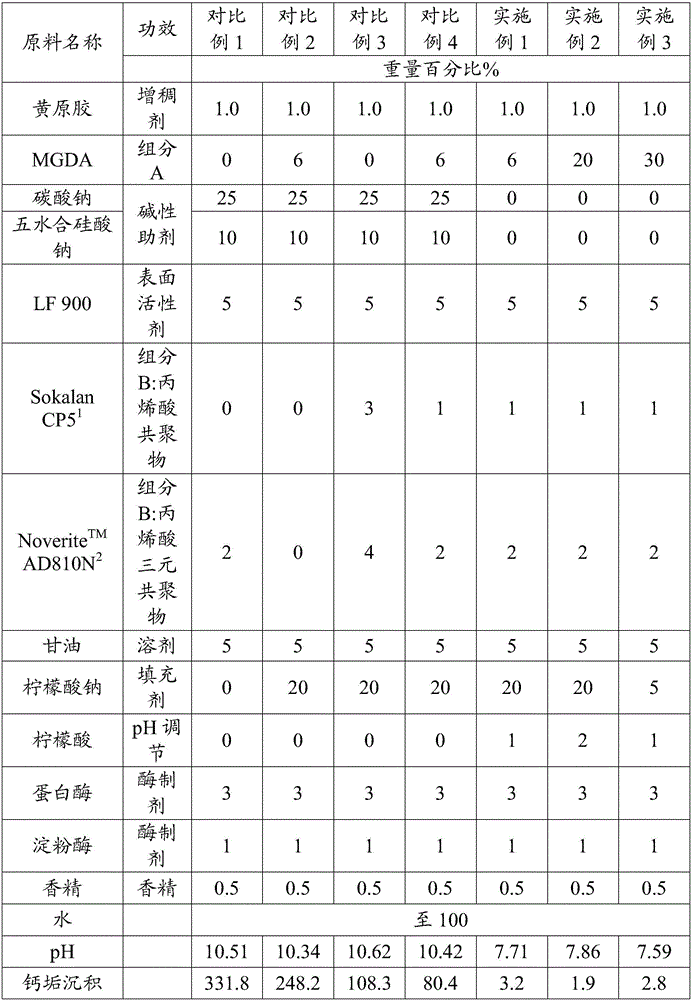

[0139] The compositions of Comparative Examples 1-2 and Examples 1-3 were formulated according to Table 1.

[0140] The composition of the domestic automatic dishwasher detergent composition of table 1 embodiment 1-3

[0141]

[0142]

[0143] 1. Purchased from BASF; 2. Purchased from Lubrizol.

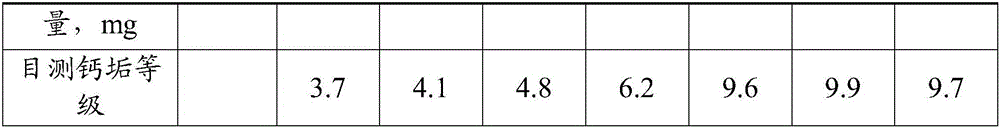

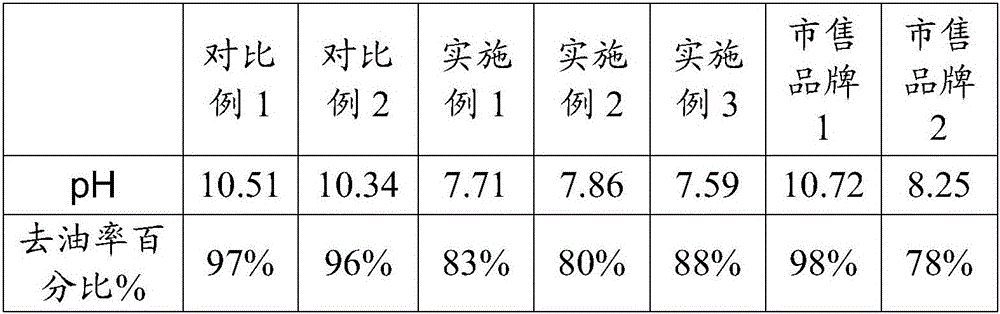

[0144] The pH measurement results show that the pH of Comparative Examples 1 to 4 is strongly alkaline after being diluted with pure water according to 1% mass ratio, and the anti-scaling performance test experiment also shows that the calcium ion content is as high as 331.8mg, 248.2mg, 108.3mg, and 80.4mg, that is, there is obvious calcium scale deposition. However, the pH of the 1% dilutions of Examples 1 to 3 is all within the pH7 to 8 range, which is a neutral and mild detergent, and the anti-scaling performance test shows that the calcium ion content is less than 10 mg, and there is no visible calcium scale on the heating tube. deposits, so heating tubes and shiny dishes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com