Lubricating oil for gearboxes and preparation method thereof

A lubricating oil and gearbox technology, applied in the field of lubricating oil, can solve the problems of increasing the power consumption of the gearbox, accelerating the wear of the working surface of the parts, high temperature, etc., achieving good fluidity and dispersion, improving high temperature resistance, and excellent comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

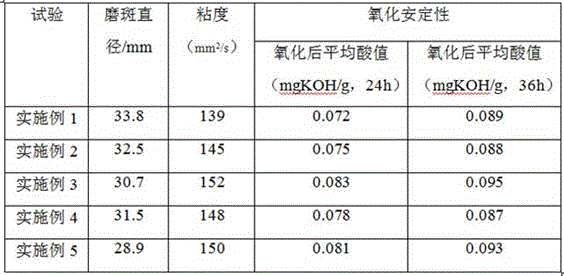

Examples

Embodiment 1

[0022] (1) Add 5 parts of tin oxide, 2 parts of cerium oxide, 1 part of neodymium oxide and 3 parts of lanthanum oxide into the grinder to grind and mix thoroughly, then add 10 parts of glycerol to it, and disperse ultrasonically for 5 minutes at a temperature of 35°C and 2200W , to get mixture A;

[0023] (2) Add 10 parts of tetraethyl silicate and 15 parts of N-phenyliminodiacetic acid to the mixture A described in step (1), stir and react at a temperature of 80°C at a speed of 850r / min for 30min to obtain a mixture B;

[0024] (3) Mix 3 parts of 5-aminobenzimidazolone, 6 parts of dibenzyl disulfide, 15 parts of tricresyl phosphate, 12 parts of sorbitol and 4 parts of di-tert-butyl p-cresol, and stir at a temperature of 80°C Reacted for 20min to obtain mixture C;

[0025] (4) Add the mixture A obtained in step (1), the mixture B obtained in step (2) and the mixture C obtained in step (3) to 60 parts of base oil, and vigorously shear and stir at 180°C for 1 hour, and contin...

Embodiment 2

[0027] (1) Add 8 parts of tin oxide, 5 parts of cerium oxide, 4 parts of neodymium oxide and 6 parts of lanthanum oxide into the grinder to grind and mix thoroughly, then add 20 parts of glycerol to it, and disperse ultrasonically at 35°C and 2200W for 10 minutes , to get mixture A;

[0028] (2) Add 5 parts of tetraethyl silicate and 20 parts of N-phenyliminodiacetic acid to the mixture A described in step (1), and stir the reaction at a temperature of 100°C at a speed of 850r / min for 40min to obtain a mixture B;

[0029] (3) Mix 7 parts of 5-aminobenzimidazolone, 2 parts of dibenzyl disulfide, 10 parts of tricresyl phosphate, 18 parts of sorbitol and 8 parts of di-tert-butyl p-cresol, and stir at a temperature of 60°C Reacted for 30min to obtain mixture C;

[0030] (4) Add the mixture A obtained in step (1), the mixture B obtained in step (2) and the mixture C obtained in step (3) to 80 parts of base oil, and vigorously shear and stir at 200°C for 0.5h, and continue to rais...

Embodiment 3

[0032] (1) Add 6 parts of tin oxide, 3 parts of cerium oxide, 2 parts of neodymium oxide and 4 parts of lanthanum oxide into the grinder to grind and mix thoroughly, then add 12 parts of glycerol to it, and disperse ultrasonically at 35°C and 2200W for 7 minutes , to get mixture A;

[0033] (2) Add 7 parts of tetraethyl silicate and 16 parts of N-phenyliminodiacetic acid to the mixture A described in step (1), and stir the reaction at a temperature of 80°C at a speed of 850r / min for 35min to obtain a mixture B;

[0034] (3) Mix 5 parts of 5-aminobenzimidazolone, 3 parts of dibenzyl disulfide, 12 parts of tricresyl phosphate, 13 parts of sorbitol and 6 parts of di-tert-butyl p-cresol, and stir at a temperature of 65°C Reacted for 25min to obtain mixture C;

[0035] (4) Add the mixture A obtained in step (1), the mixture B obtained in step (2) and the mixture C obtained in step (3) to 65 parts of base oil, and vigorously shear and stir at 185°C for 1 hour, and continue to rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com