A kind of viscosity-increasing fluid loss reducing compound agent for seawater slurry and preparation method thereof

A technology of sea cement slurry and fluid loss control agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of easy agglomeration or mildew, difficult storage of salt-resistant glue and protective agent, and high cost, so as to prevent moisture. Mildew, good salt resistance, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In one embodiment, the preparation method at least includes the following steps:

[0028] (1) Mixing the salt-resistant vegetable gum, the salt-resistant viscosity-lifting fluid loss reducer, and the high-calcium and high-temperature-resistant polymer fluid loss reducer to obtain a mixed material;

[0029] (2) Add the modified sodium-based bentonite to the mixed material, and carry out coating mixing to obtain the seawater viscosity-increasing fluid loss compounding agent.

[0030] Preferably, the preparation method of modified sodium bentonite is as follows:

[0031] (21) After the raw ore bentonite is crushed and homogenized, the particle size is sieved to obtain the raw ore soil;

[0032] (22) Carry out mixing treatment with described raw ore soil and sodiumizing agent, salt-resistance modifier, ion modification auxiliary agent, obtain mixed material;

[0033] (23) Add water into the mixed material, and after stirring treatment, carry out stack aging treatment and ...

Embodiment 1

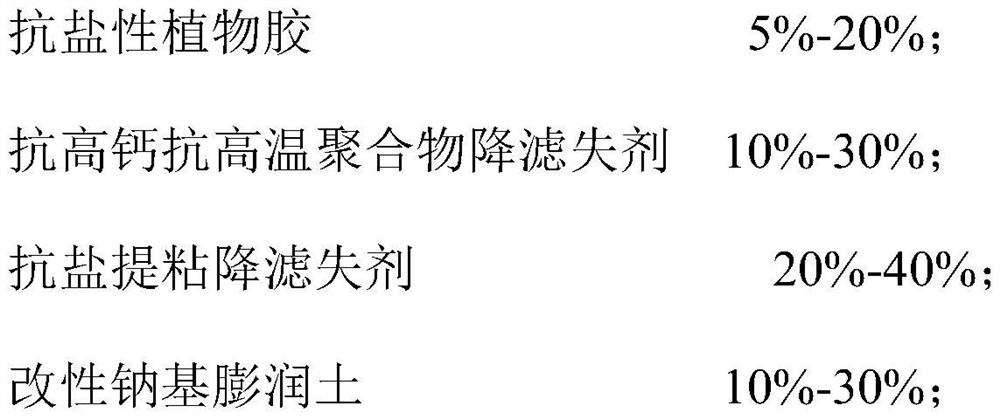

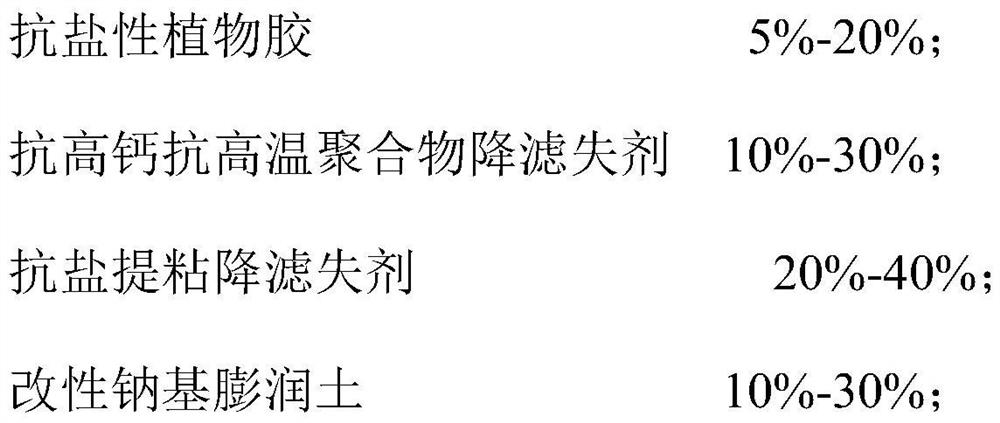

[0044] A viscosity-increasing fluid loss reducing compound agent for seawater slurry, comprising the following raw material components in mass percentage:

[0045]

[0046] The preparation method of the viscosity-increasing fluid loss reducing compound agent for seawater slurry comprises the following steps:

[0047] (1) carrying out mixing treatment with guar gum, hydroxyethyl cellulose, anti-high calcium and high temperature resistant polymer fluid loss reducer, and polyanion cellulose to obtain a mixed material;

[0048] (2) Add the modified sodium-based bentonite to the mixed material, and carry out coating mixing to obtain the seawater viscosity-increasing fluid loss compounding agent.

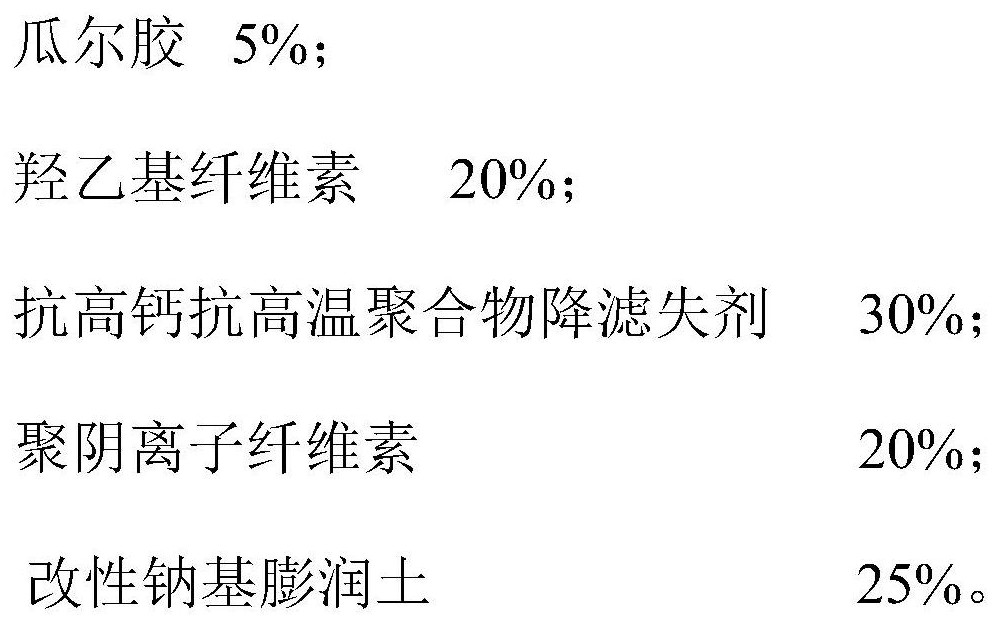

Embodiment 2

[0050]

[0051] The preparation method of the viscosity-increasing fluid loss reducing compound agent for seawater slurry comprises the following steps:

[0052] (1) carrying out mixing treatment with guar gum, hydroxyethyl cellulose, anti-high calcium and high temperature resistant polymer fluid loss reducer, and polyanion cellulose to obtain a mixed material;

[0053] (2) Add the modified sodium-based bentonite to the mixed material, and carry out coating mixing to obtain the seawater viscosity-increasing fluid loss compounding agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com