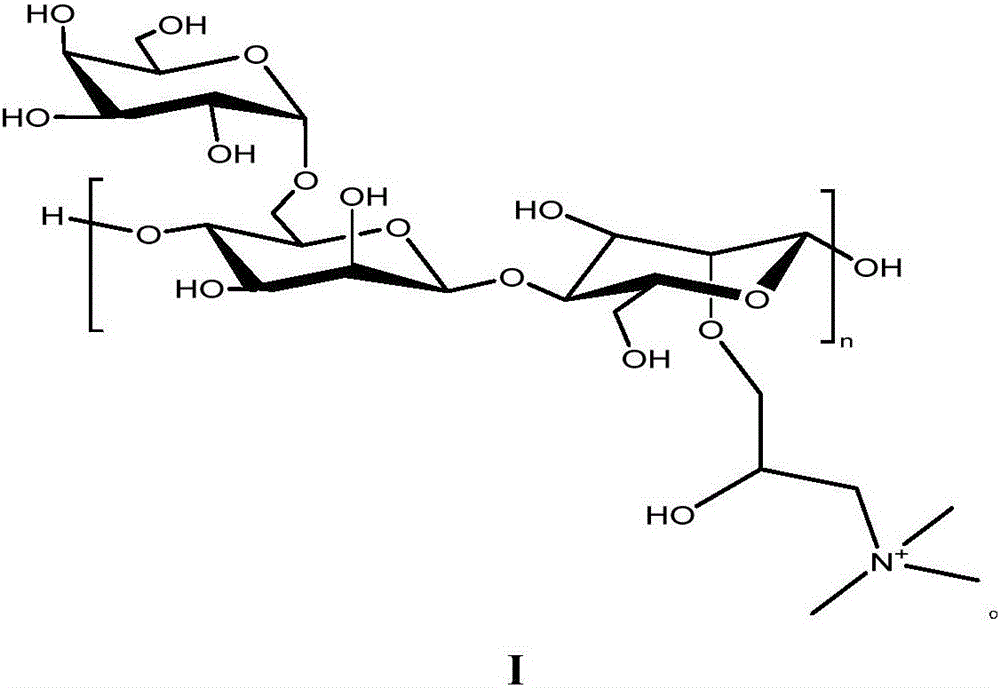

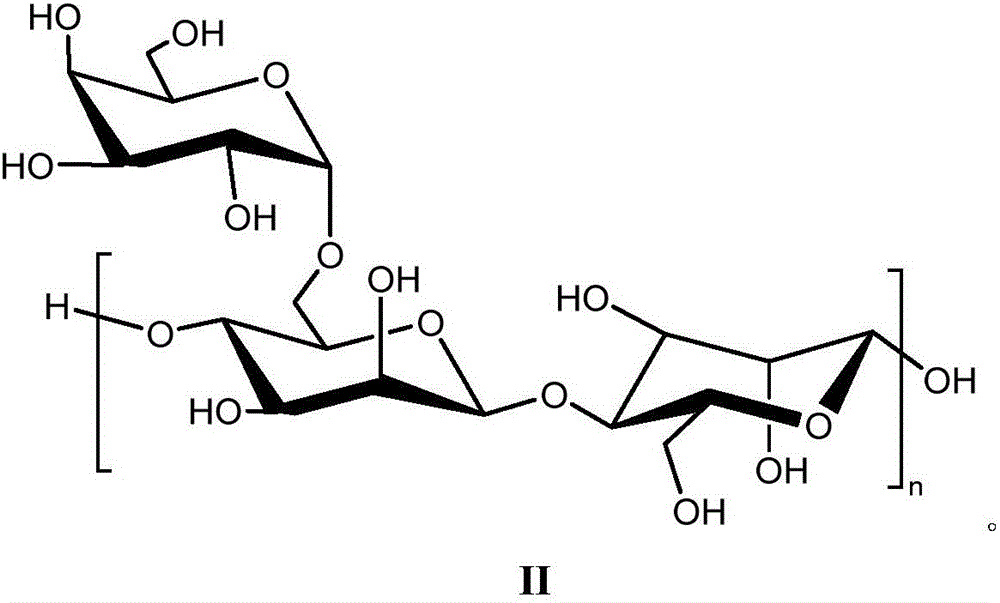

Polysaccharide hydrate dynamics inhibitor and application thereof

A kinetic inhibitor, hydrate technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as poor thermal and salt stability, and achieve the effects of stable performance, low production cost and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

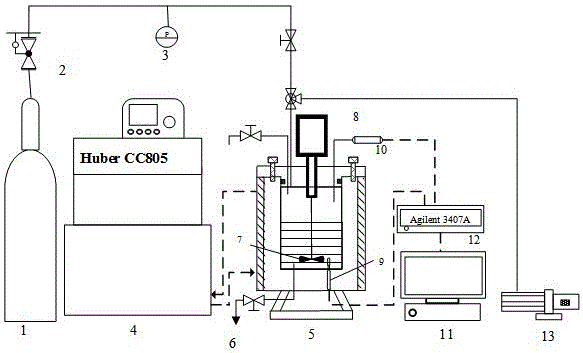

[0028] Before the reaction started, the reactor was cleaned with deionized water, and 250 g of deionized water was added. After the temperature in the reactor was stabilized at 25° C., 12.3 MPa of methane gas was introduced (the volume ratio of methane gas to deionized water was 1:4 ), turn on mechanical stirring (650rpm). After the equilibrium pressure of the dissolved gas in the kettle is stabilized (stabilized at 11.6MPa), the temperature is lowered at a rate of 2°C / h. After the hydrate is formed, the temperature is raised at a rate of 1 °C / h, and the rate of temperature increase is reduced to 0.1 °C / h at the end of the heating section, and the system CH 4 - Water-hydrate three-phase equilibrium at 14 °C.

Embodiment 2

[0032] Add 250 g of deionized water into the reaction kettle, and the mass fraction of the polysaccharide hydrate inhibitor of the present invention in the solution is 0.5 wt % guar gum. After the temperature in the reactor is stabilized at about 25°C, a 11.5MPa acidic gas mixture (CO 2 40.39%, CH 459.61%) (the volume ratio of acidic gas mixture to deionized water is 1:4), and the mechanical stirring (650rpm) was started. After the equilibrium pressure of the gas dissolved in the kettle is stabilized (stabilized at 10.4MPa), the temperature is lowered to 0.2°C at a rate of 2°C / h. The experimental results show that the durable subcooling degree of 0.5wt% guar gum against the acid mixture is 4.8°C. After the hydrate was formed, 0.32wt% of water in the system was kept to be converted into hydrate, and the temperature was lowered again to carry out the evaluation experiment of crystal growth inhibition method. The results showed that 0.5wt% guar gum completely inhibited the sup...

Embodiment 3

[0036] Add 250g deionized water in the reaction kettle, the solute in this solution is 0.5wt% guar gum and 3.5wt% NaCl. After the temperature in the reactor is stabilized at about 25°C, a 11.5MPa acidic gas mixture (CO 2 40.39%, CH 4 59.61%) (the volume ratio of acidic gas mixture to deionized water is 1:4), and the mechanical stirring (650rpm) was started. After the equilibrium pressure of the gas dissolved in the kettle is stabilized (stabilized at 10.4MPa), the temperature is lowered to 0.2°C at a rate of 2°C / h. The experimental results show that 0.5wt% guar gum can increase the durable subcooling degree of the acid mixture to 5.8°C. After the hydrate was formed, 0.32wt% of water in the system was kept to be converted into hydrate, and the temperature was lowered again to carry out the evaluation experiment of crystal growth inhibition method. The results show that the range of supercooling in the zone of complete inhibition of 0.5wt% guar gum is 0℃~3.27℃, the range of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com