Eccentric reciprocating type press-fitting cutting packaging device and packaging machine adopting device

A reciprocating drive device, reciprocating technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of laborious stop to start, machine vibration and noise, unstable operation, etc., to reduce the need for return travel. time, increase the processing speed, and ensure the effect of the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

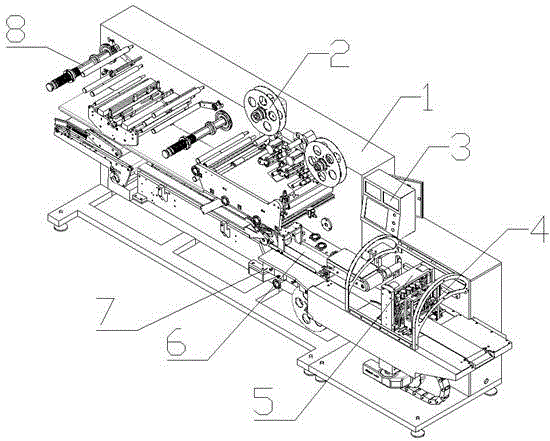

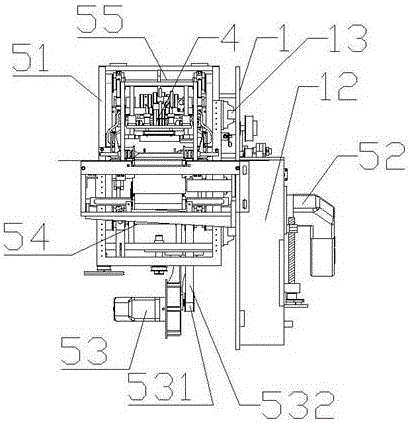

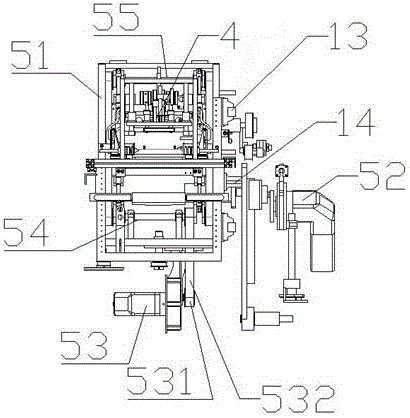

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] see Figure 2 to Figure 10, an eccentric reciprocating pressing and cutting packaging device 5, comprising a frame 1, a knife rest 51, a horizontal reciprocating movement mechanism of the knife rest, an upper and lower knife rest reciprocating pressing, cutting and opening mechanism, and the knife rest 51 is arranged on the frame 1 One side, between frame 1 and knife rest 51, be provided with knife rest slide pair 13, knife rest slide pair 13 comprises knife rest slide rail and knife rest slide block, and knife rest slide block is fixed on knife rest 51 top, and knife rest The slide rail is fixed on the frame 1, and the frame is also provided with a horizontal slide channel and a drag slider 14 located in the horizontal slide channel, the drag slider 14 is fixed on the tool holder, and the upper and lower tool holders are pressed back an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com