Method for strengthening regeneration of organic phase after desulphurization and decarburization of phase change absorber

An organic phase and absorbent technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of affecting the regeneration process, slow regeneration process, and low regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

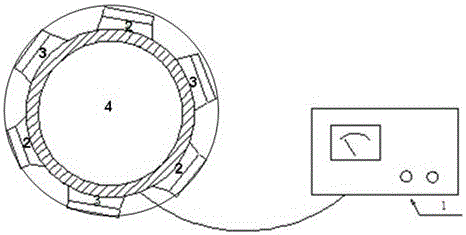

Image

Examples

Embodiment 1

[0024] CO in flue gas 2 (Volume ratio) is 12.5%, and the rest are tested under the air source condition of air. When the gas flow rate is 10 L / min, the absorption temperature is 40°C, the amine concentration (mass ratio) of the phase-change absorbent is 20%, the solution circulation rate is 0.05 L / min, and the frequency of the standing wave sound field in the regeneration tower is 80 kHz, ultrasonic The sound intensity is 0.3 W / cm 2 , The regeneration temperature is 105.8°C. The experimental results show that the regeneration rate of the organic phase can reach 85% by using this technology.

Embodiment 2

[0026] SO in flue gas 2 (Volume ratio) is 1.8%, and the rest are tested under the air source condition of air. When the gas flow rate is 100 mL / min, the absorption temperature is 40 °C, the amine concentration (mass ratio) of the phase change absorbent is 20%, the frequency of the standing wave sound field in the boiler is 50 kHz, and the ultrasonic sound intensity is 0.8 W / cm 2 , the experimental results show that using this technology, the ultrasonic irradiation time is 5 minutes, and the regeneration rate of the organic phase in the absorbent reaches 70%.

Embodiment 3

[0028] Considering the synergistic effect of absorption temperature and ultrasound, experiments were carried out to increase the absorption temperature. CO in flue gas 2 (Volume ratio) is 12.5%, and the rest are tested under the air source condition of air. When the gas flow rate is 10 L / min, the absorption temperature is 60°C, the amine concentration (mass ratio) of the phase-change absorbent is 20%, the solution circulation rate is 0.05 L / min, and the frequency of the standing wave sound field in the boiler is 80 kHz, ultrasonic The sound intensity is 0.3 W / cm 2 , The regeneration temperature is 106.0°C. The experimental results show that the regeneration rate of the organic phase can reach 76.6% by using this technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com