Low-sensitivity foam concrete foaming agent and preparation method of foaming agent

A foamed concrete and foaming agent technology, applied in the field of building material admixtures, can solve the problems of increased bulk density of flowing foamed concrete, decreased fluidity of foamed concrete, unfavorable product quality control, etc., and achieves good foaming power and easy speed control. , suitable for large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

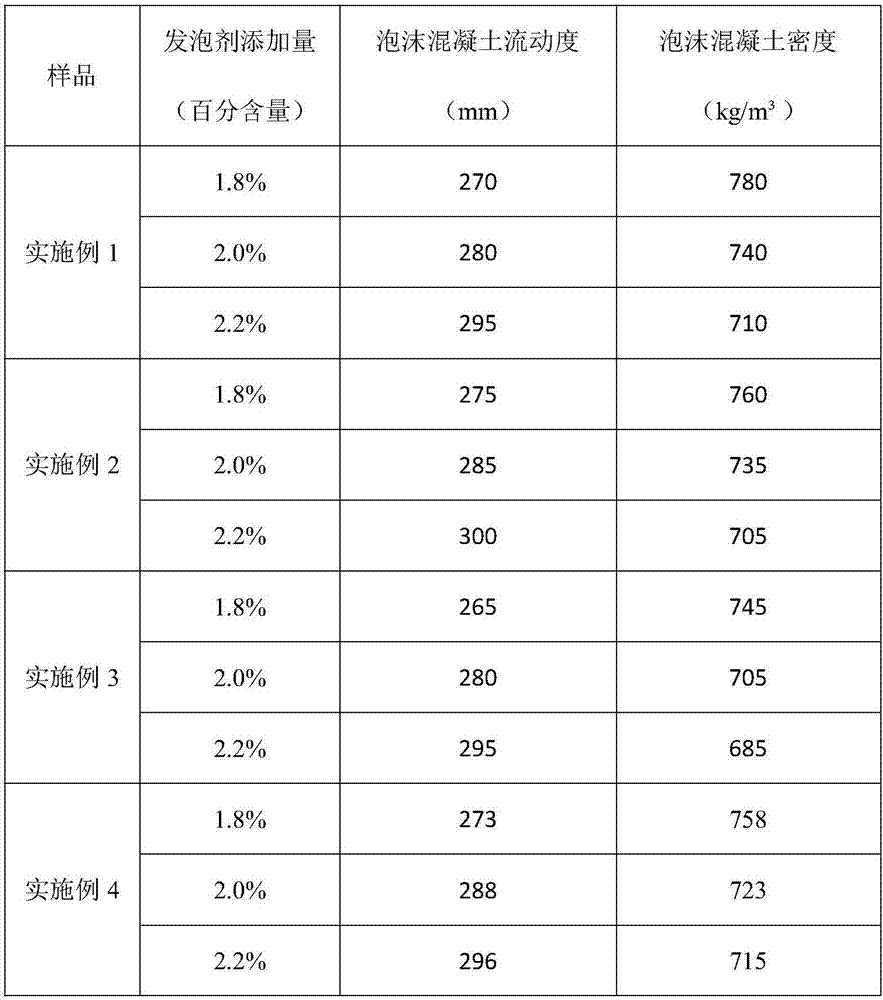

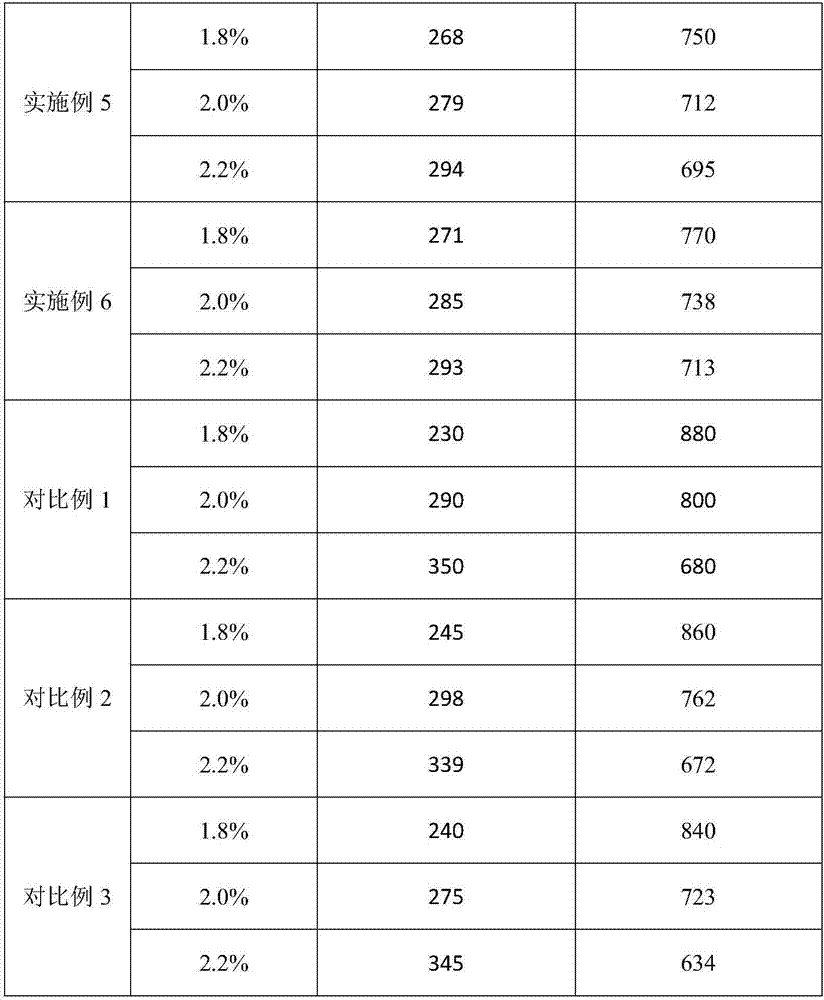

Examples

Embodiment 1

[0015] A low-sensitivity foam concrete blowing agent, its preparation method comprises the following steps:

[0016] (1) Weigh each raw material component according to the following parts by weight: 50 parts of aliphatic polyoxyethylene ether, 18 parts of sulfamic acid, 3 parts of composite catalyst, 20 parts of saturated sodium hydroxide solution, modified silicone resin polyether microemulsion 2 parts, 80 parts of water, wherein the molar ratio of the composite catalyst is n (urea): n (ferric chloride hexahydrate)=2:1;

[0017] (2) Under the protection of nitrogen, the fatty alcohol polyoxyethylene ether, sulfamic acid, and composite catalyst were heated up to 95°C while stirring, then kept stirring for 2 hours, and then cooled to a temperature of 50°C;

[0018] (3) Add saturated sodium hydroxide solution while stirring in the product that step (2) obtains, carry out cooling simultaneously, make temperature not exceed 60 ℃.

[0019] (4) add water to the product obtained in ...

Embodiment 2

[0021] A low-sensitivity foam concrete blowing agent, its preparation method comprises the following steps:

[0022] (1) Weigh each raw material component according to the following parts by weight: 50 parts of fatty alcohol polyoxyethylene ether, 16 parts of sulfamic acid, 4 parts of composite catalyst, 25 parts of saturated sodium hydroxide solution, modified silicone resin polyether microemulsion 2.5 parts, 85 parts of water. Wherein the molar ratio of the composite catalyst is n (urea): n (ferric chloride hexahydrate)=1.5:1;

[0023] (2) Under the protection of nitrogen, mix the aliphatic polyoxyethylene ether, sulfonating agent, and catalyst and heat up to 100°C while stirring, then keep stirring for 3 hours, and then cool down to 55°C;

[0024] (3) adding saturated sodium hydroxide solution while stirring to the product obtained in step (2), while cooling so that the temperature does not exceed 60°C;

[0025] (4) add water to the product obtained in step (3) to dilute,...

Embodiment 3

[0027] A low-sensitivity foam concrete blowing agent, its preparation method comprises the following steps:

[0028] (1) Weigh each raw material component according to the following parts by weight: 45 parts of fatty alcohol polyoxyethylene ether, 19 parts of sulfamic acid, 3.5 parts of composite catalyst, 17 parts of saturated sodium hydroxide solution, modified silicone resin polyether microemulsion 2 parts, 80 parts of water. Wherein the molar ratio of the composite catalyst is n (urea): n (ferric chloride hexahydrate)=1:1;

[0029] (2) Under the protection of nitrogen, mix the aliphatic polyoxyethylene ether, sulfonating agent, and catalyst and heat up to 105°C while stirring, then keep stirring for 1.5 hours, and then cool down to 45°C;

[0030] (3) adding saturated sodium hydroxide solution while stirring to the product obtained in step (2), while cooling so that the temperature does not exceed 60°C;

[0031] (4) add water to the product obtained in step (3) to dilute,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com