Method and device for preparing building gypsum by phosphogypsum

A technology of building gypsum and phosphogypsum, which is applied in the field of preparing building gypsum, can solve the problems of human living environment hazards, soil air pollution, and low comprehensive utilization rate, and achieve the goals of avoiding natural stacking and aging, reducing environmental pollution, and shortening the production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

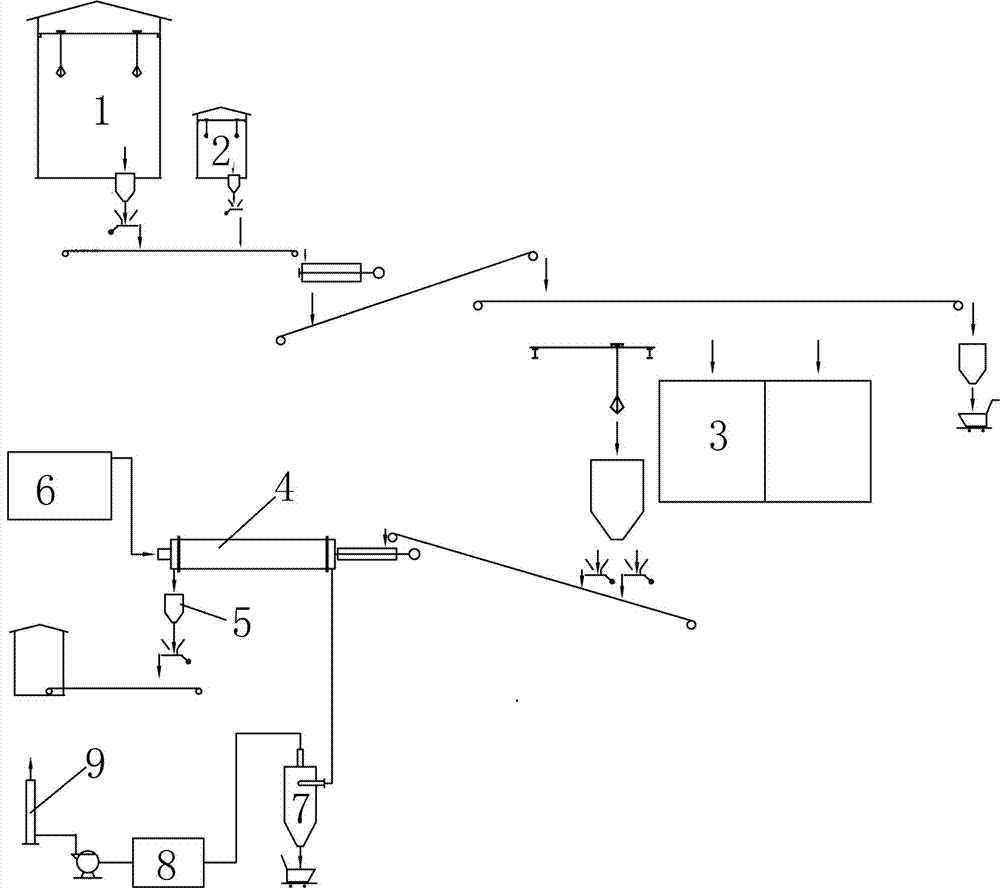

Method used

Image

Examples

Embodiment 1

[0025] The phosphogypsum slurry obtained from a chemical plant in Xiaoting, Yichang, Hubei, after pressure filtration, the pH value of the sample is 2.36, and the composition analysis results are shown in Table 1 (in wt%):

[0026] P 2 o 5

F -

CaO

SO 3

SiO 2

K 2 o

Na 2 o

Al 2 o 3

Fe 2 o 3

Cl -

loss

crystal water

total

0.41

0.04

28.9

41.3

6.65

0.17

0.06

0.44

0.03

0.003

2.67

19.1

99.71

[0027] Table 1

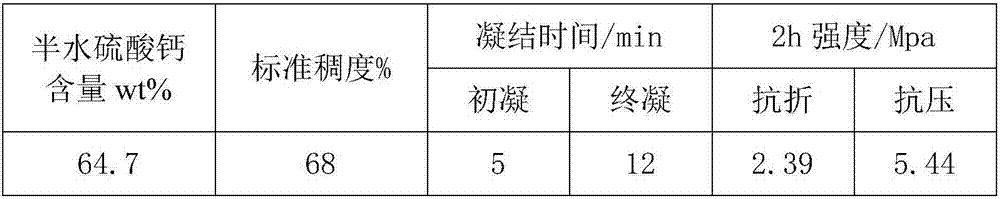

[0028] The sample and quicklime were mixed and stirred evenly at a ratio of 99.2:0.8, put into the retting warehouse for retting at 38°C for 30 hours, and the pH value was continuously sampled and analyzed to be 5.88, then sent to the calciner for calcination, and the flue gas temperature 720°C, outlet flue gas temperature 135°C, calcination time 30min, then send the material into the homogenizing cooling silo, and leave it for 24h to obtain a q...

Embodiment 2

[0032] Mix and stir the same sample and quicklime in the ratio of 99:1 evenly in Example 1, put it into the retting warehouse for retting for 45 hours at 38°C, continuously sample and analyze the pH value to be 6.79, send it to the calciner for calcination, and The furnace flue gas temperature is 730°C, the outlet flue gas temperature is 135°C, and the calcination time is 45 minutes. Finally, the material is sent to the homogenizing cooling silo, and the qualified product is obtained after standing for 24 hours. The performance analysis results of the finished product are shown in Table 3:

[0033]

[0034]

[0035] table 3

Embodiment 3

[0037] The phosphogypsum slurry was taken from a chemical plant in Yidu, Yichang, Hubei. After pressure filtration, the pH value of the sample was 2.58. The composition analysis results are shown in Table 4, and the unit is wt%.

[0038] P 2 o 5

F -

CaO

SO 3

SiO 2

K 2 o

Na 2 o

al 2 o 3

Fe 2 o 3

Cl -

loss

crystal water

total

0.44

0.03

29.12

39.9

6.89

0.15

0.05

0.52

0.04

0.002

2.43

20.31

99.84

[0039] Table 4

[0040] The sample and quicklime were mixed and stirred evenly at a ratio of 98.5:1.5, put into the retting warehouse for retting at 40°C for 50 hours, and the pH value was continuously sampled and analyzed to be 7.84, and sent to the calciner for calcination. 720°C, outlet flue gas temperature 135°C, calcination time 45min, then send the material into the homogenizing cooling silo, and leave it for 24h to obtain a qualified product. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com