Oily chemical wastewater treatment equipment and treatment method

A technology for chemical wastewater and treatment equipment, applied in the field of water treatment, can solve the problems of cumbersome operation and management, slow gas-liquid mixing, large floor space, etc., and achieve the effects of convenient use, increased water pressure, and increased water flow power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

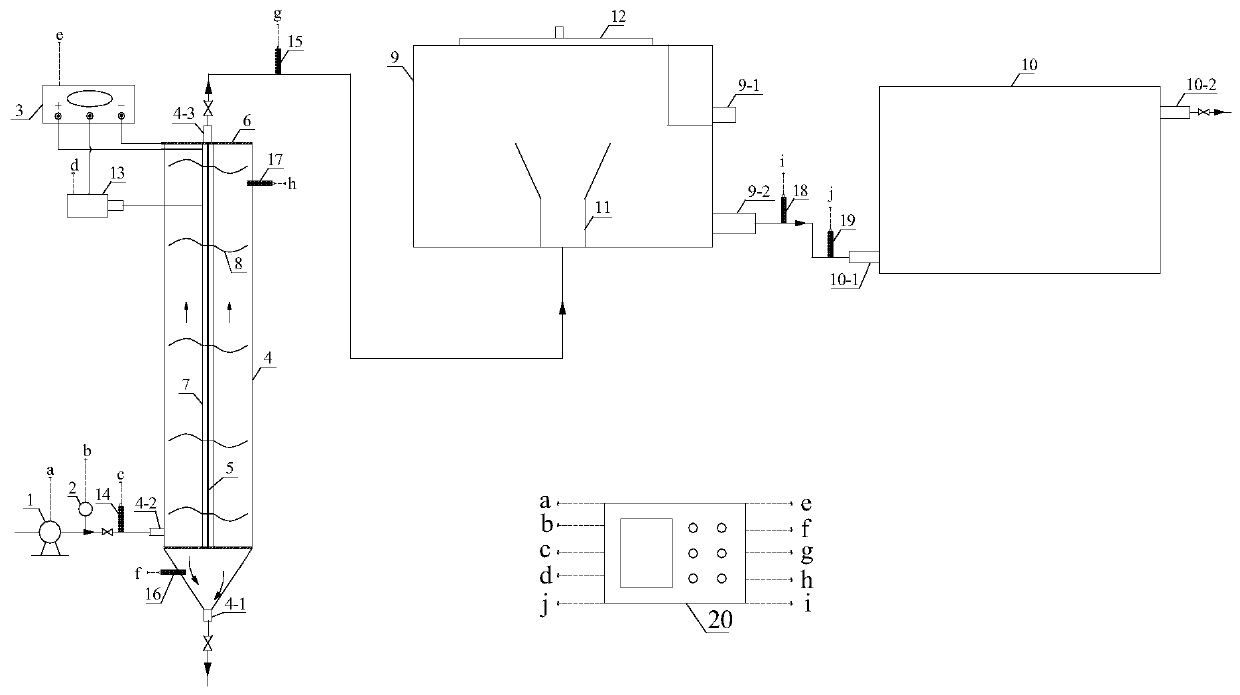

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

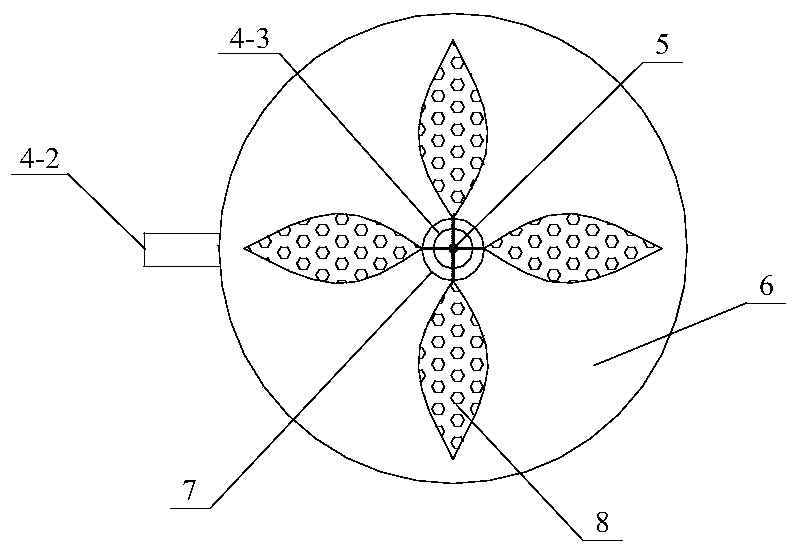

[0042] Such as figure 1 and figure 2 As shown, an oil-containing chemical wastewater treatment equipment includes an inlet pump 1 , a power supply 3 , a reaction device 4 , an axial cathode 5 , a spiral anode, an air flotation device 9 , a biochemical treatment device 10 and an automatic control unit 20 .

[0043] The above-mentioned power supply is preferably a DC or pulse power supply or the like.

[0044] The reaction device is installed vertically, and the material can be metal or non-metal. When it is a metal tube, the inner wall is insulated. The reaction device includes a cylindrical reaction part and a sewage discharge part located below the cylindrical reaction part.

[0045] The bottom side wall of the cylindrical reaction part is provided with a raw water inlet 4-2, and the water inlet pump is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com