Coffee machine

A technology for coffee machines and components, which is applied in the field of beverage preparation equipment, and can solve problems such as inaccuracy, high energy consumption, and difficult temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0137] In order to make the technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

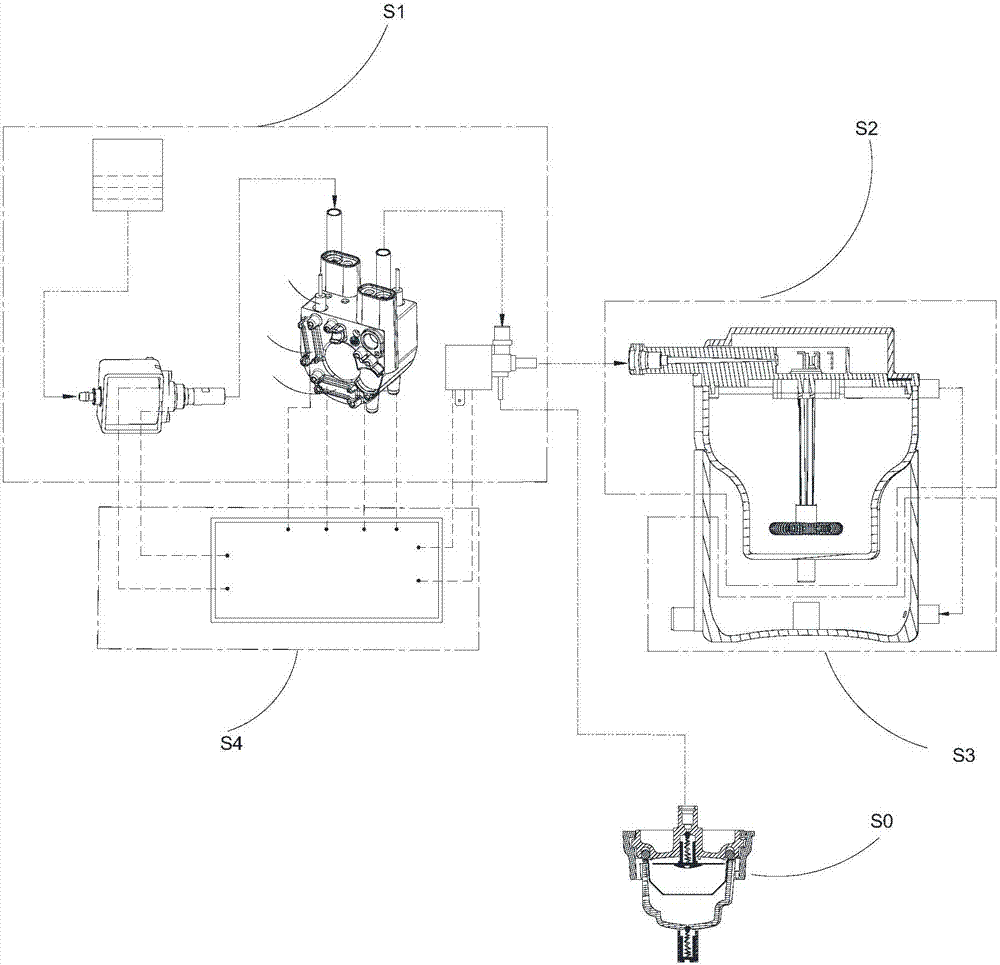

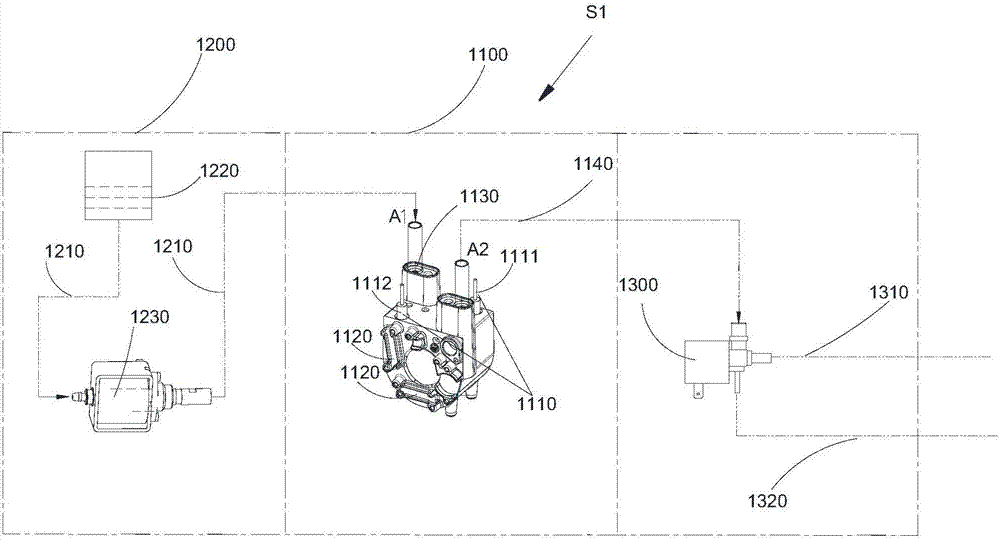

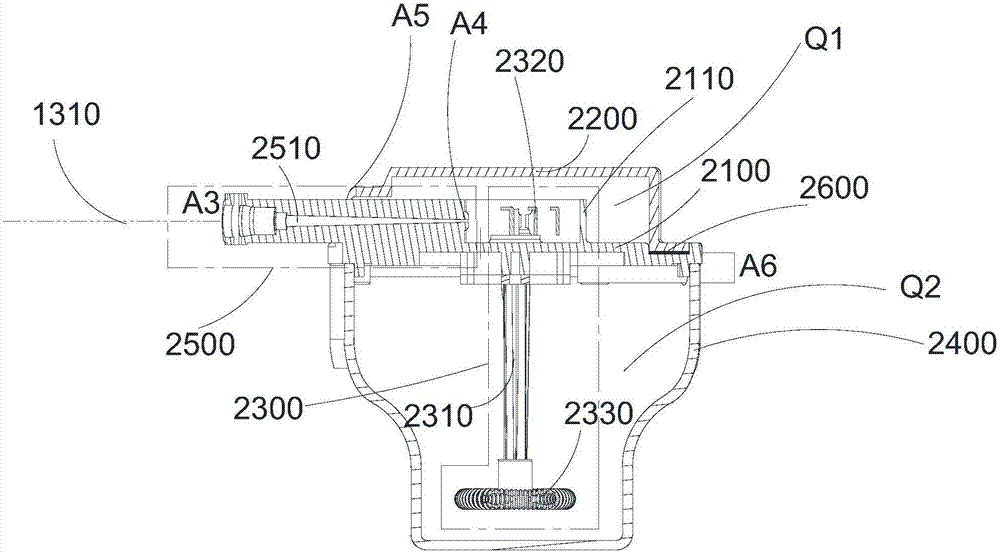

[0138] see figure 1 As shown, the coffee machine of the present invention includes a brewing system S0, a steam preparation system S1, a stirring system S2, a foaming heating system S3 and a control system S4. The steam production system S1 can produce steam or hot water. The steam production system S1 can transport the steam it produces to the stirring system S2 to drive the stirring system S2 to stir the foaming liquid to make it foam. The steam production system S1 can also prepare it The steam or hot water is sent to the brewing system S0 to prepare coffee. The foaming heating system S3 receives the low-pressure steam or the hot water condensed from the steam after the steam preparation system S1 drives the stirring system S2 to heat the foaming liquid. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com