High-flux heat transfer plate and tube with porous surface and plate reboiler

A porous surface and high-throughput technology, applied in heat exchange equipment, chemical instruments and methods, lighting and heating equipment, etc., can solve warpage and deformation waste rate, low stiffness of high-throughput plates, poor deformation resistance, etc. problems, to achieve the effects of improving yield, enhancing boiling heat transfer, and high resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

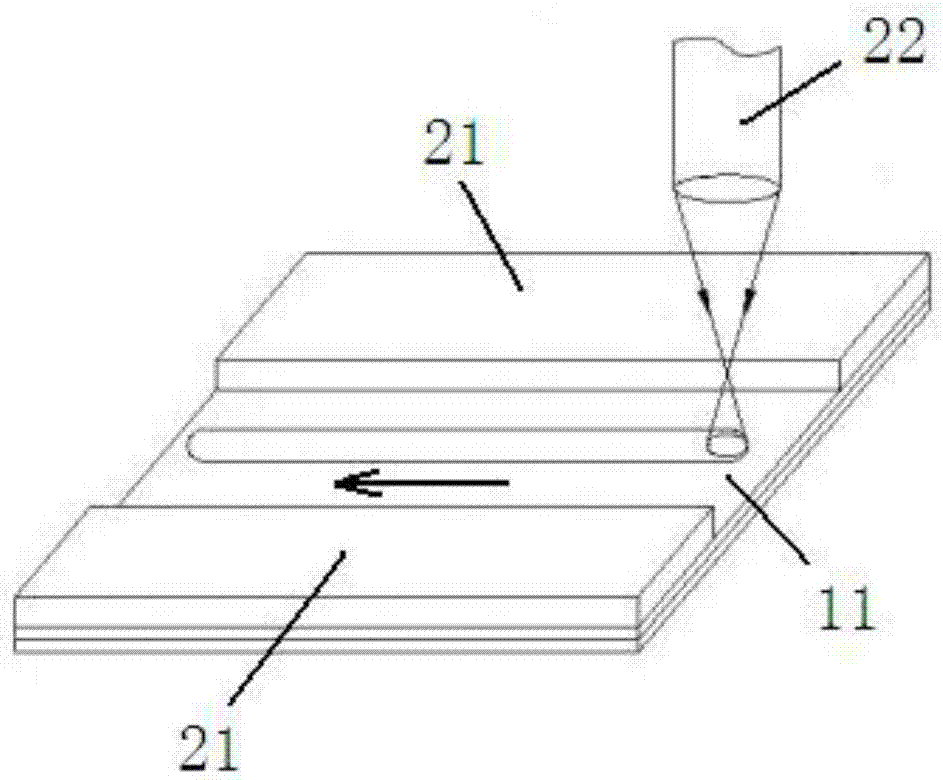

[0033] The technical solution of the present invention will be further introduced below in conjunction with the accompanying drawings.

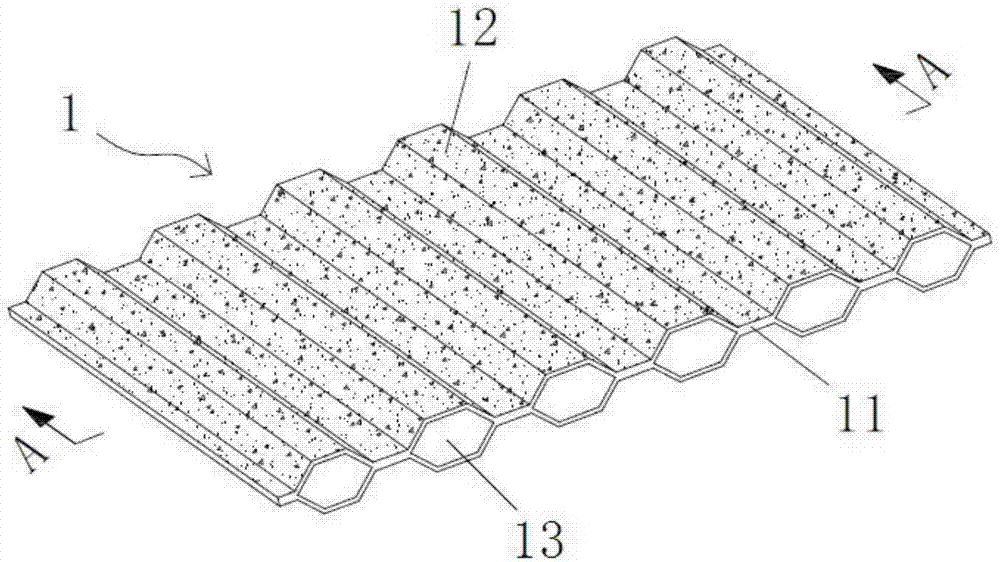

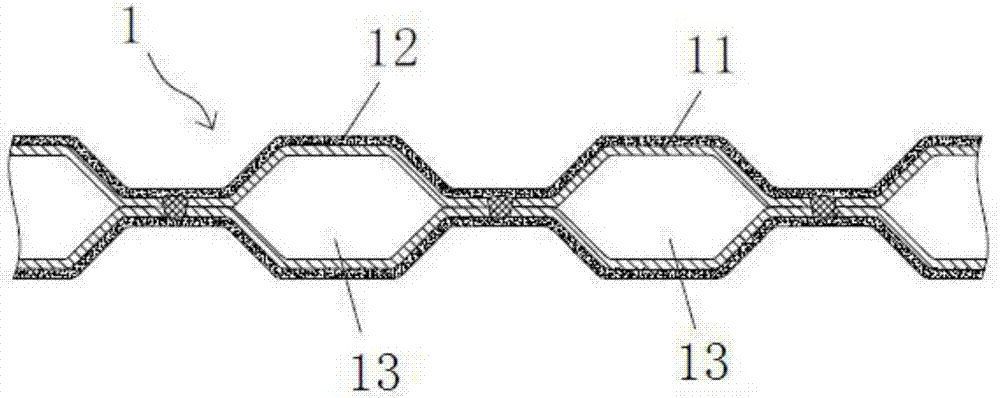

[0034] combine figure 1 and figure 2 As shown, the surface porous high flux heat transfer plate tube 1 of the present invention includes a plate tube base 11 and a porous metal layer 12 . The plate tube base 11 is formed by pairing upper and lower heat transfer corrugated plates. Adjacent surface-porous high-flux heat transfer plate tubes 1 are arranged in parallel at a certain distance, and the enclosed space is used as a low-temperature medium side channel. Adjacent sheets of the porous high-flux heat transfer plate tube 1 on the same surface form through holes 13 as high-temperature medium flow channels.

[0035] Preferably, the heat transfer corrugated plate is made by molding process, and the wall surface of the heat transfer corrugated plate is sinusoidally corrugated along the flow direction. The thickness of the heat transfer cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com