A kind of egb air-cooled two-stroke gasoline engine oil composition and preparation method thereof

A gasoline engine oil and two-stroke technology, applied in the field of lubricating oil, can solve problems such as shortening the service life of spark plugs, reducing engine power, and straining the air intake surface, achieving low mixing performance, reducing friction, and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

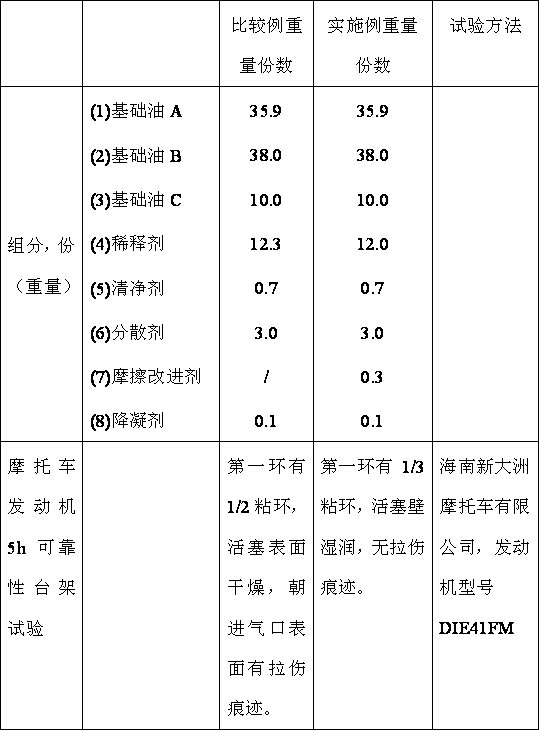

Embodiment 1

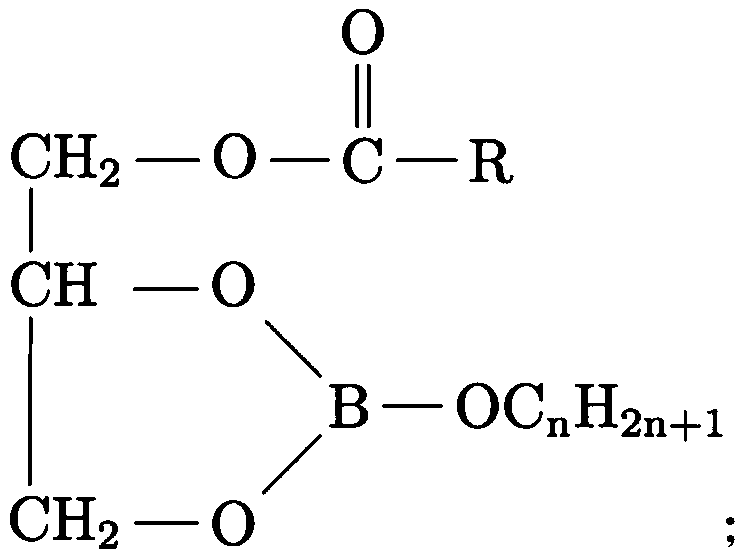

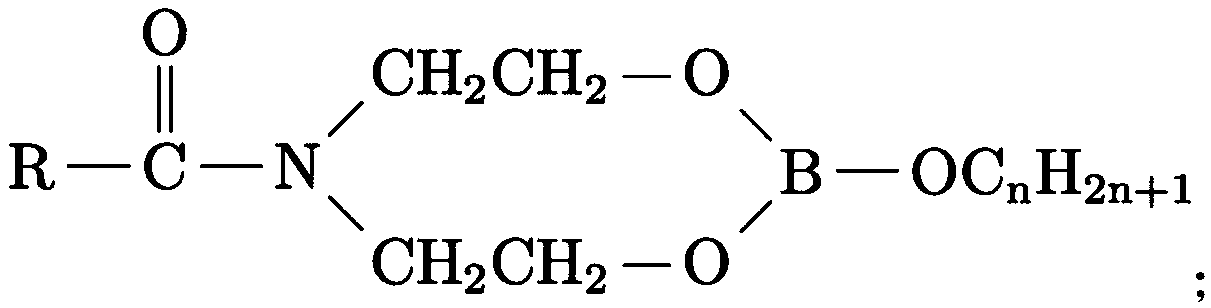

[0039] Prepare a kind of EGB air-cooled two-stroke gasoline engine oil composition, formula is as follows: the base oil of 35.9 parts-I type base oil 150N, the base oil B of 38.0 parts-I type base oil 650N, the base oil C of 10.0 parts-bright oil 130BS, 0.7 parts of detergent-calcium sulfonate with low alkali value of 20-30 mgKOH / g total base value, 3.0 parts of dispersant-disuccinimide of 15-30 mgKOH / g total base value, 0.3 parts friction modifier—a boron nitrogen compound with a boron content of 1.4% and an acid value less than or equal to 10mgKOH / g, 0.1 parts of a pour point depressant—Viscoplex 1-156 and 12.0 parts of a diluent—aviation kerosene;

[0040] The preparation method is as follows: Add base oil A, base oil B, and base oil C in sequence, stir well at 75°C for 0.5-1 hour and mix evenly, then add detergent, dispersant, friction modifier, and pour point depressant in proportion Continue to stir for 3 hours to make it completely dissolved, then cool down to 45°C and ...

Embodiment 2

[0042]A kind of EGB air-cooled two-stroke gasoline engine oil composition is prepared, and the formula is as follows: 35 parts of base oil A—Class I base oil 150N, 38 parts of base oil B—Class I base oil 650N, 12 parts of base oil C—bright Oil 120BS, 0.5 parts of detergent-low-basic calcium sulfonate with a total base value of 20-30 mgKOH / g, 3.5 parts of dispersant-disuccinimide with a total base value of 15-30 mgKOH / g, 0.4 1 part of friction modifier - boron nitrogen compound with boron content of 1.4%, acid value ≤ 10mgKOH / g, 0.1 part of pour point depressant - Viscoplex1-156 and 10.5 parts of diluent - aviation kerosene;

[0043] The preparation method is as follows: add base oil A, base oil B, and base oil C in sequence, stir well at 70°C for 0.5 to 1 hour and mix evenly, then add detergent, dispersant, friction modifier, and pour point depressant in proportion Continue to stir for 3 hours to make it completely dissolved, then cool down to 40°C and then add diluent and sti...

Embodiment 3

[0045] Prepare a kind of EGB air-cooled two-stroke gasoline engine oil composition, formula is as follows: 39 parts of base oil A—Ⅱ group base oil 150N, 40 parts of base oil B—Ⅱ group base oil 650N, 8 parts of base oil C—bright Oil 120BS, 0.8 parts of detergent-calcium sulfonate with low basic value of 20-30mgKOH / g, 2.9 parts of dispersant-disuccinimide of 15-30mgKOH / g, 0.3 1 part of friction modifier - boron nitrogen compound with boron content 1.4%, acid value ≤ 10mgKOH / g, 0.1 part of pour point depressant - Viscoplex1-156, 8.9 parts of diluent - aviation kerosene;

[0046] The preparation method is as follows: add base oil A, base oil B, and base oil C in sequence, stir well at 70°C for 0.5 to 1 hour and mix evenly, then add detergent, dispersant, friction modifier, and pour point depressant in proportion Continue to stir for 3 hours to make it completely dissolved, then cool down to 40°C and then add diluent and stir for 3 hours until the mixture is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com