Novel DOPO-type epoxy resin curing agent and preparation method of same

A new type of compound technology, applied in the field of epoxy resin curing agent, can solve the problems of easy fire and restriction, and achieve the effect of not easy to seep out, small performance and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) in N 2 Under the atmosphere, put a thermometer, condensing reflux, magnetic stirring and N 2 Add DOPO (0.01mol), p-nitrobenzaldehyde (0.01mol) and ethanol (10 mL) into a 250 mL three-neck flask that was passed through, start heating and stirring to dissolve completely, then raise the temperature to 60°C, and 2 Reaction under protective atmosphere for 8h.

[0027] (2) After the reaction is finished, cool to room temperature, filter with suction to obtain a crude product, rinse with deionized water, repeat 3 times, and finally dry in a vacuum oven at 80° C. for 24 hours to obtain an intermediate product.

[0028] (3) Mix the intermediate product (0.01mol) obtained in step (2), iron powder (0.035mol) and hydrochloric acid solution (containing 0.065mol of hydrogen chloride), and stir at room temperature to react quickly, and then add it to the dilute NaOH solution And, extracted and purified with ethyl acetate to obtain the final product.

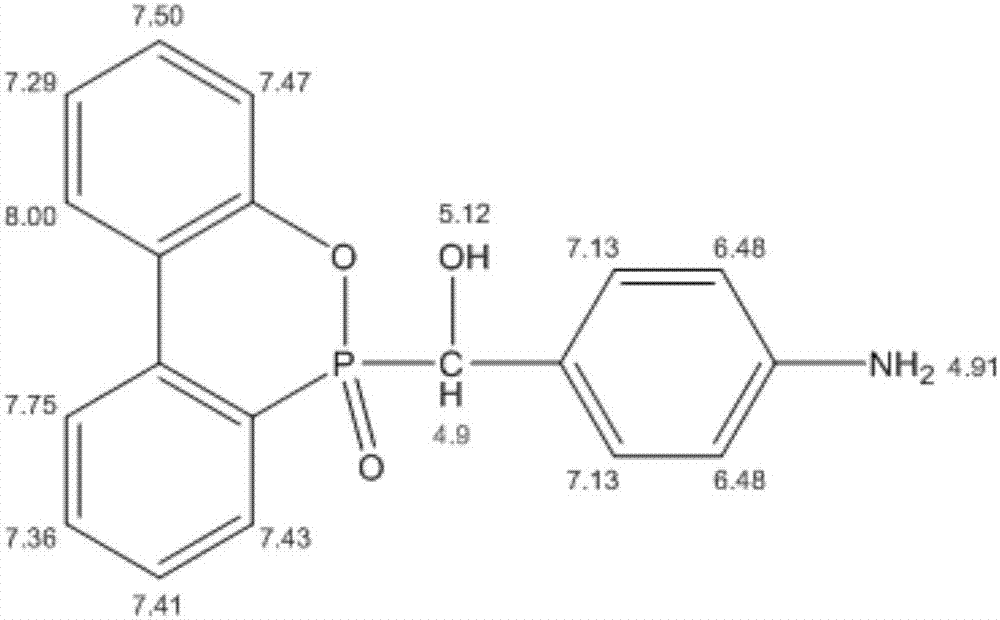

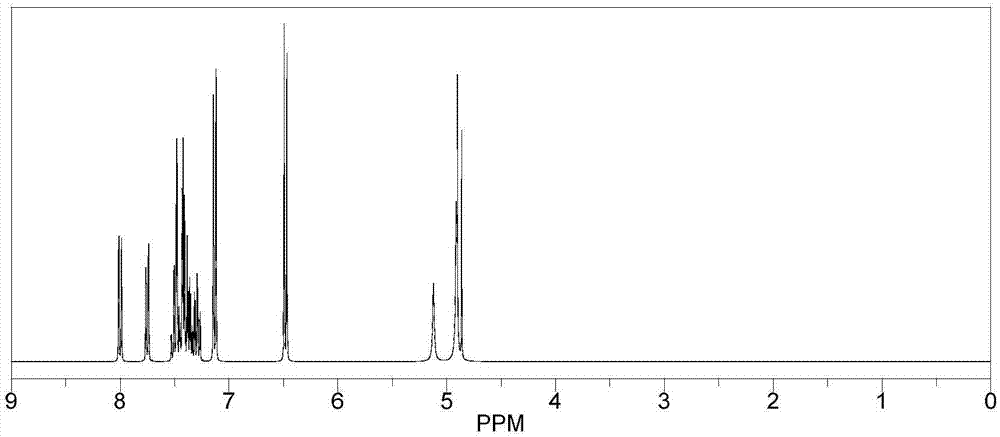

[0029] figure 1 For the n...

Embodiment 2

[0033] in N 2 Under the atmosphere, put a thermometer, condensing reflux, magnetic stirring and N 2 Add DOPO (0.01mol), p-nitrobenzaldehyde (0.015mol) and ethanol (10mL) in the 250mL three-neck flask that passes through, start to heat and stir to make it dissolve completely, then be warming up to 60 ℃, under N 2 Under the atmosphere of reaction 8h, subsequent steps are the same as steps (2) and (3) in embodiment 1.

Embodiment 3

[0035] in N 2 Under the atmosphere, put a thermometer, condensing reflux, magnetic stirring and N 2 Add DOPO (0.01mol), p-nitrobenzaldehyde (0.015mol) and ethanol 10mL into the 250mL three-necked flask that has been passed through, start heating and stirring to make it dissolve completely, then raise the temperature to 75°C, and 2 Under the atmosphere of reaction 8h, subsequent steps are the same as steps (2) and (3) in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com