Preparation method of environment-friendly fermented organic fertilizer

An organic fertilizer and environment-friendly technology, which is applied in the field of preparation of environment-friendly fermented organic fertilizers, can solve problems such as crop diseases, insects, weeds, harm to human health, environmental pollution, etc. The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

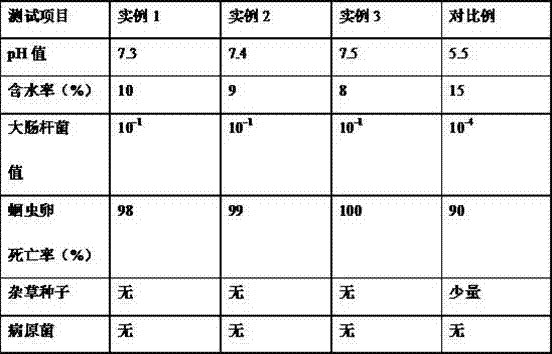

Examples

example 1

[0023] In parts by weight, weigh 13 parts of rice bran, 12 parts of rapeseed cake, 11 parts of soybean meal, 6 parts of sugarcane, 45 parts of deionized water, 1 part of zeolite powder and 1 part of yogurt, first cut the sugarcane into lengths Add deionized water to the sugarcane small pieces of 2cm and mix and stir for 8 minutes. After stirring, add rice bran, rapeseed cake and soybean meal in turn and continue mixing and stirring for 1 hour. After stirring, stack them in the greenhouse. Ferment for 20 days, and finally add zeolite powder and yogurt and stir and mix for 6 minutes. The material is discharged, which is the self-made fermentation ripening powder. According to the mass ratio of 1:1:1, the biogas slurry, sludge and chicken manure are naturally air-dried for 15 days to obtain Air-dried waste, in parts by weight, weighed 3 parts of humic acid, 1 part of polyvinyl alcohol, 2 parts of urea, 1 part of potassium dihydrogen phosphate and 6 parts of deionized water and mix...

example 2

[0025] In parts by weight, weigh 14 parts of rice bran, 13 parts of rapeseed cake, 12 parts of soybean meal, 7 parts of sugar cane, 55 parts of deionized water, 2 parts of zeolite powder and 2 parts of yogurt, first cut the sugar cane into length Add deionized water to the sugarcane small pieces of 2cm and mix and stir for 9 minutes. After stirring, add rice bran, rapeseed cake and soybean meal in turn and continue mixing and stirring for 1.5 hours. Ferment for 30 days, and finally put in zeolite powder and yogurt and mix for 7 minutes, and the material will be self-made fermentation ripening powder. According to the mass ratio of 1:1:1, the biogas slurry, sludge and chicken manure are naturally air-dried for 17 days. To obtain the air-dried waste, weigh 4 parts of humic acid, 2 parts of polyvinyl alcohol, 3 parts of urea, 2 parts of potassium dihydrogen phosphate and 7 parts of deionized water and mix and stir for 10 minutes to obtain the mixed solution. In terms of parts by ...

example 3

[0027]In parts by weight, weigh 15 parts of rice bran, 14 parts of rapeseed cake, 13 parts of soybean meal, 8 parts of sugar cane, 65 parts of deionized water, 3 parts of zeolite powder and 3 parts of yogurt, first cut the sugar cane into length Add deionized water to the sugarcane small pieces of 3 cm and mix and stir for 10 minutes. After stirring, add rice bran, rapeseed cake and soybean meal and continue mixing and stirring for 2 hours. Ferment for 40 days, and finally add zeolite powder and yogurt and mix for 8 minutes, and the material is discharged, which is self-made fermentation ripening powder. According to the mass ratio of 1:1:1, the biogas slurry, sludge and chicken manure are naturally air-dried for 20 days to obtain Air-dried waste, in parts by weight, weighed 5 parts of humic acid, 3 parts of polyvinyl alcohol, 4 parts of urea, 3 parts of potassium dihydrogen phosphate and 8 parts of deionized water and mixed and stirred for 12 minutes to obtain a mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com