a c/tib 2 Surface Treatment Methods of Composite Materials

A composite material and surface treatment technology, applied in the field of surface treatment of carbon fiber reinforced ceramic matrix composite materials, can solve the problems of composite material damage, fiber silicon corrosion, large volume expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare C / TiB as follows 2 Composite materials, the steps are as follows:

[0036] (1), liquid phenolic resin (solid content is 50 wt%) is dispersed in dehydrated alcohol, guarantees that the content of liquid phenolic resin in the dispersion is 2 wt%;

[0037] (II), the TiO 2 Powder and B 4 C powder is added to the solution obtained in step (I), and stirred evenly at 40°C; wherein TiO 2 Powder and B 4 The mass ratio of the total amount of C powder to absolute ethanol is 1:1, TiO 2 Powder and B 4 The mass ratio of C powder is 1.2:1;

[0038] (III), according to carbon fiber powder (length 45μm) and TiO 2 The mass ratio of the powder is 0.14:1. Add the carbon fiber powder into the solution obtained in step (II), and continue stirring at 60°C until the slurry becomes too thick to stir;

[0039] (IV), put the slurry in a drying oven, and dry at 90°C; after granulating through a 100-mesh sieve, put the powder in a mold, and press it at 180MPa to obtain a green body;...

Embodiment 2

[0047] C / TiB 2 The preparation of the composite material is the same as in Example 1.

[0048] C / TiB 2 The surface treatment steps of composite materials are as follows:

[0049] (1), use B 4 C powder embedding C / TiB obtained by siliconizing 2 For composite materials, react at 1000°C for 5 hours in vacuum, for strengthening the surface of composite materials;

[0050] (2), according to mass ratio Ti powder: NH 4 Cl:Al 2 o 3 =85:3:12, Ti powder, NH 4 Cl, Al 2 o 3 The powder is placed in a ball mill jar, and ball milled for 60 minutes to obtain a mixed powder;

[0051] (3) Embed the C / TiB treated in step (1) with the mixed powder obtained in step (2) 2 For the composite material, react in vacuum at 1300°C for 3 hours, and then cool down naturally.

Embodiment 3

[0053] C / TiB 2 The preparation of the composite material is the same as in Example 1.

[0054] C / TiB 2 The surface treatment steps of composite materials are as follows:

[0055] (1), use B 4 C powder embedding C / TiB obtained by siliconizing 2 Composite materials, reacted at 900°C for 5.5 hours in vacuum, used to strengthen the surface of composite materials;

[0056] (2), according to mass ratio Ti powder: NH 4 Cl:Al 2 o 3 =75:3:22, Ti powder, NH 4 Cl, Al 2 o 3 The powder is placed in a ball mill jar, and ball milled for 30 minutes to obtain a mixed powder;

[0057] (3) Embed the C / TiB treated in step (1) with the mixed powder obtained in step (2) 2 For the composite material, react in vacuum at 1250°C for 5 hours, and then cool down naturally.

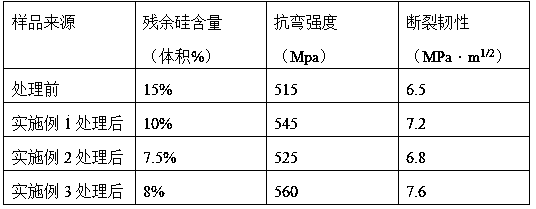

[0058] C / TiB 2 See the following table for the residual silicon content and performance data of the composite material before and after the method of the present invention.

[0059]

[0060] As can be seen from the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com