Porous carbon material, preparation method and application thereof

A technology of porous carbon materials and carbonization process, applied in the field of carbon materials, can solve problems such as collapse, achieve uniform distribution of pore size, large specific surface area and porosity, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of a porous carbon material.

[0036] The preparation method of the porous carbon material provided by the present invention includes the preparation of the precursor: dissolving the metal salt and the organic acid in the organic solvent, adding the additive, stirring and centrifuging to obtain the precursor, the metal salt, the organic acid, The molar ratio of the additives is 1-10:1-10:0-100; the preparation of the porous carbon material: after mixing the precursor and the proppant, carbonize it under the protection of an inert gas, wash and dry it to obtain The porous carbon material, wherein the proppant includes inorganic salts.

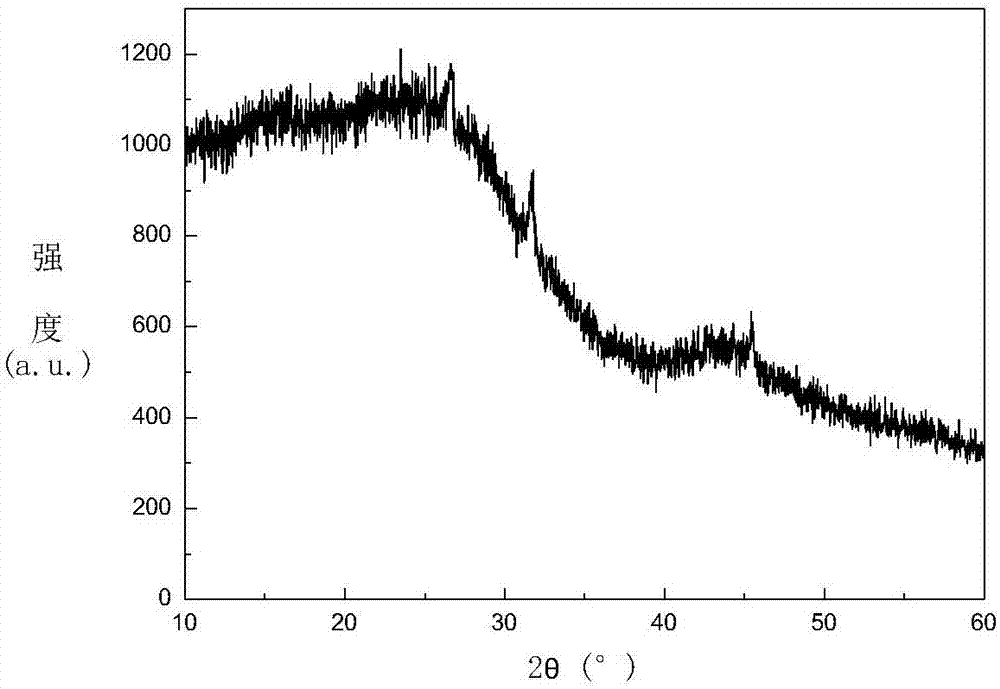

[0037] In the preparation method of the porous carbon material provided by the present invention, a proppant is added during the carbonization process of the precursor, and the proppant is melted at a certain temperature, and enters the pores formed during the carbonization process, and acts as ...

Embodiment 1

[0054] This embodiment provides a method for preparing a porous carbon material and the prepared porous carbon material.

[0055] Weigh 3.33g (18.4mmol) of 2-aminoterephthalic acid and 14.42g (48.5mmol) of zinc nitrate hexahydrate and dissolve in DMF (360mL), add 20mL (143.5mmol) of triethylamine, and stir at room temperature for 30 minutes . Centrifuge and wash the resulting solid with N,N-dimethylformamide (DMF) and chloroform (CHCl 3 ) were washed three times, and finally dried in an oven at 80° C. for 24 hours to obtain a light yellow IRMOF-3 material.

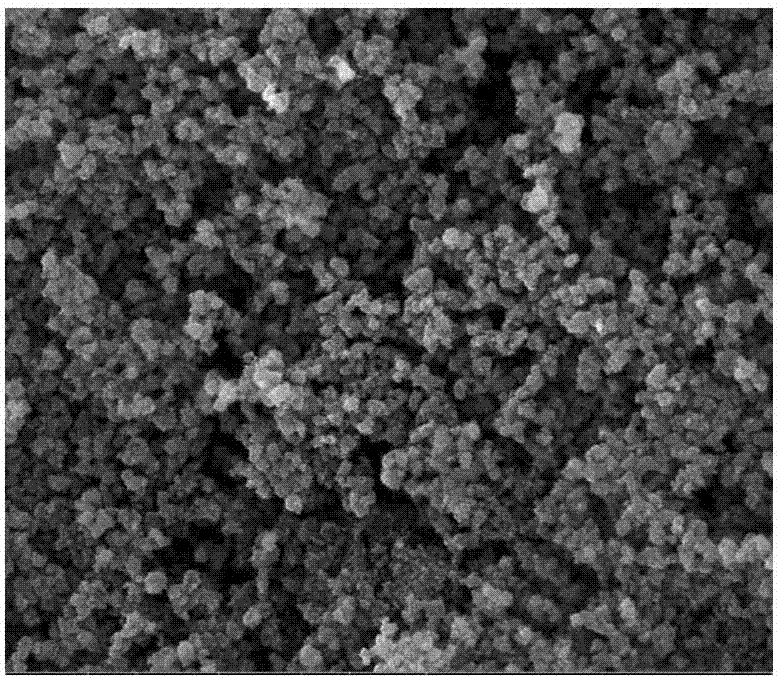

[0056] After mixing 3 grams of Zn elemental substance and 6 grams of NaCl with the IRMOF-3 material obtained above, put them into a tube furnace, N 2 Under protection, the temperature was raised to 1000 °C at a rate of 5 °C / min, and after 6 hours of heat preservation, it was naturally cooled to room temperature, and the obtained porous carbon material was named 3C-1000 (NaCl).

Embodiment 2

[0068] This embodiment provides a method for preparing a porous carbon material and the prepared porous carbon material.

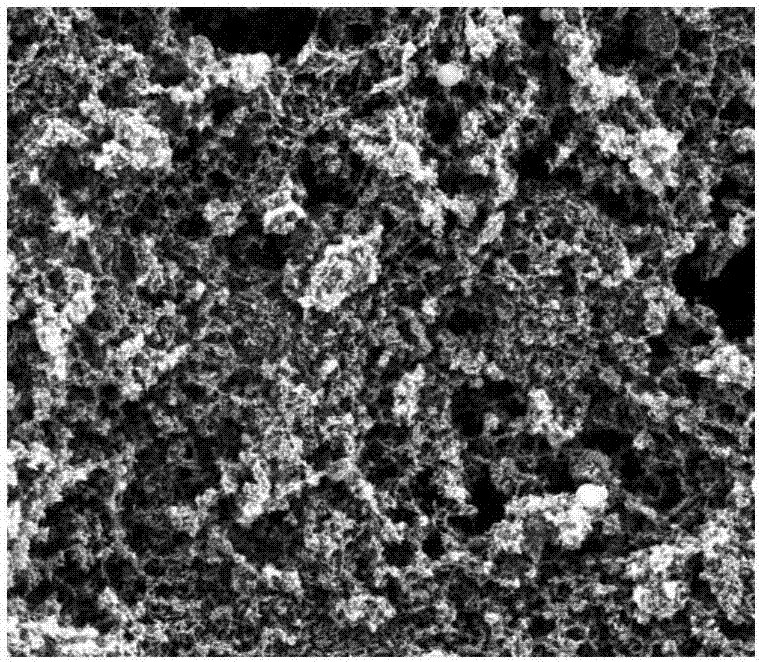

[0069] The proppant used in this example is 9 grams of Zn simple substance, and other preparation processes are the same or similar to Example 1.

[0070] The physical properties of the porous carbon material prepared in this example are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com