Butt welding structure and butt welding equipment

A technology of butt welding and material shifting mechanism, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated welding process and low welding efficiency, and achieve consistent welding depth, firm welding, The effect of improving labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

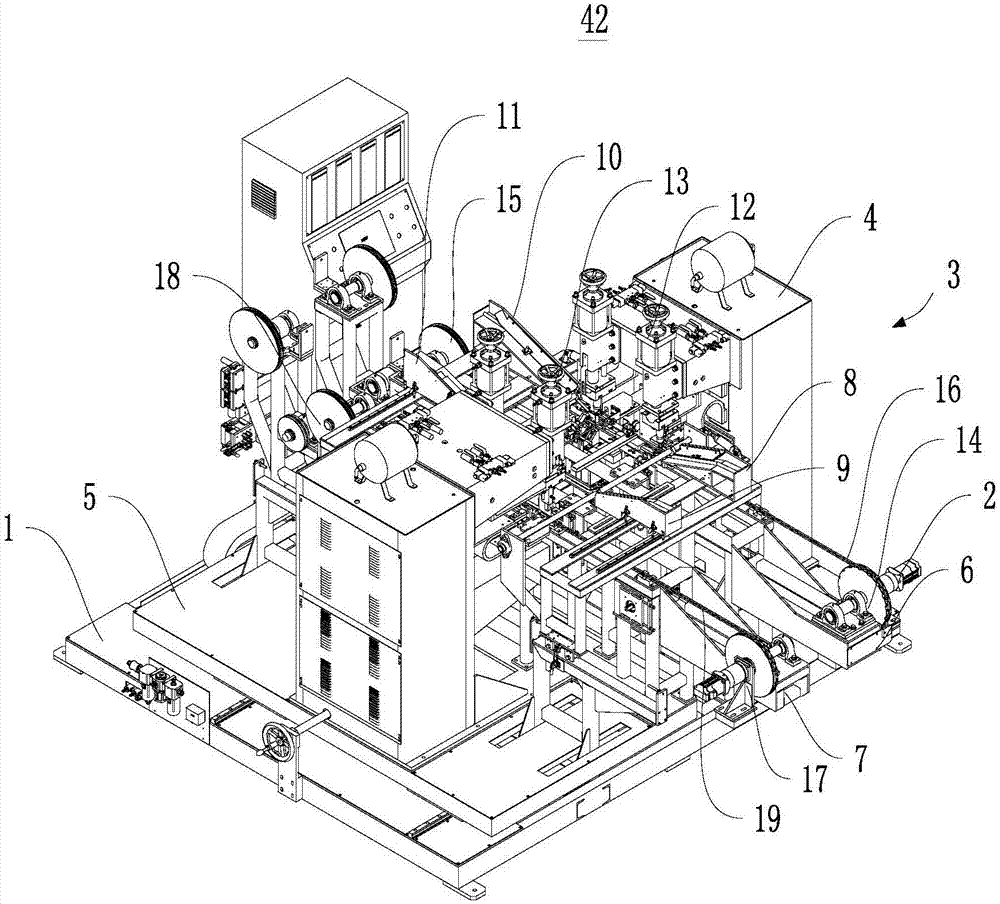

[0038] Please refer to figure 1 , with reference to Figure 2 to Figure 6 , the present embodiment provides a kind of butt welding equipment 42, and it comprises linear bar 39, broken line bar 40 and butt welding structure 1; On the butt welding structure 1, the straight rod 39 and the broken line rod 40 are respectively welded to the welding chain 41 by starting the pressurized cylinder.

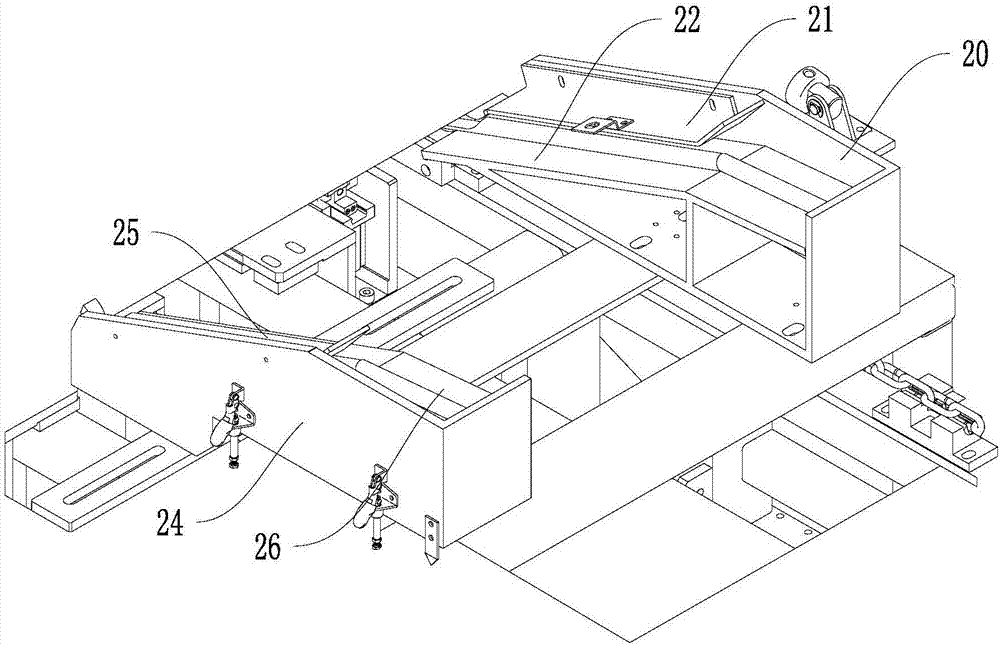

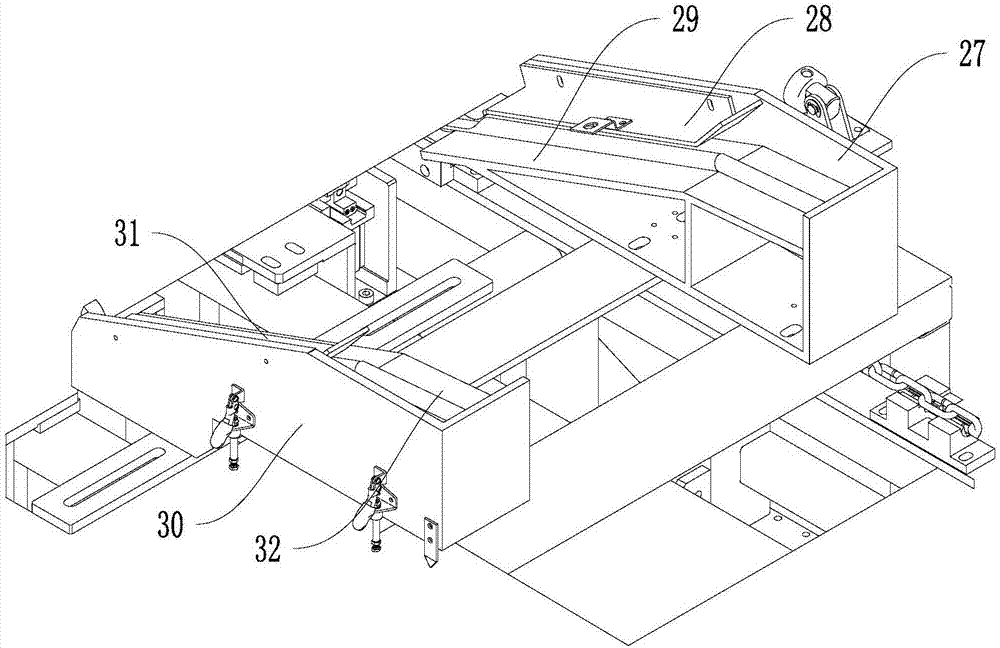

[0039] Further, the butt welding structure 1 includes a servo feed mechanism 2, a material shifting mechanism 3, a clamping calibration mechanism 4, and a support frame 5; the servo feed mechanism 2 includes a first transmission assembly 6 and a second transmission assembly 7, and the first transmission assembly Component 6 and the second conveying component 7 are spaced and arranged on the support frame 5 in parallel; the material shifting mechanism 3 includes a first straight line shifter 8, a second straight line shifter 9, a first folding line shifter 10 and a second straight line shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com