Working method of aluminum wire machining hot sawing machine

A working method and technology of a thermal saw machine, applied in the cutting field, can solve the problems of increasing cutting difficulty, easily damaged cutting devices, and increasing cutting hardness, and achieve the effects of high cutting efficiency, easy cutting and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

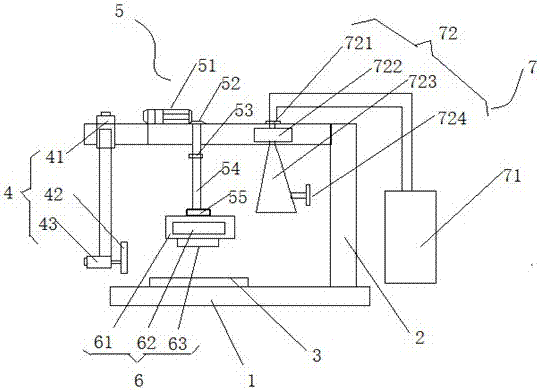

[0025] Such as figure 1 The working method of a hot saw machine for processing aluminum wire is shown. The hot saw machine includes a base 1, a frame 2, a cutting table 3, a workpiece pushing device 4, a lifting punching device 5, a saw blade heating and cutting device 6, and a workpiece cooling device. Device 7, the frame 2 is set on the left side of the base, the lifting punching device 5 is set on the frame 2, the saw blade heating and cutting device 6 is installed at the lower end of the punching lifting device 5, and the cutting table 2 is set in the middle of the base 1 , and located directly below the punching lifting device 5, the workpiece pushing device 4 is fixed on the base 1, and is arranged on the left side of the cutting table 2, and the workpiece cooling device 7 is arranged on the right side of the cutting table 2. The saw blade heating and cutting device 6 includes a saw blade fixing seat 61, a heating device 62 and a saw blade 63, the saw blade 63 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com