Preparation method of metal organic skeleton compound and oxidized graphene composite microspheres having uniform appearance

A metal-organic framework and graphene composite technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of uneven product morphology, difficult industrialization, and difficult to control, and achieve improved conductivity, uniform size, high The effect of nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing metal-organic framework compound / graphene oxide composite microspheres with uniform appearance, the steps are as follows:

[0034] Disperse ZIF-8 and graphene oxide in deionized water respectively to prepare a ZIF-8 dispersion with a concentration of 2 mg / mL and a graphene oxide dispersion with a concentration of 2 mg / mL, and slowly add ZIF-8 to the graphene oxide In the dispersion, stir while adding, the mixing ratio is 1:1, and then spray-dry the obtained mixed solution. The spray-drying conditions are: the inlet air temperature is 150°C, the feeding speed is adjusted by a peristaltic pump, and the feeding speed is 10mL / min, the compressed air flow rate is 600L / h, the compressed air pressure is 5-8bar, and the airflow velocity is 35m 3 / h, and the outlet air temperature was 80°C to prepare ZIF-8 / GO composite microspheres.

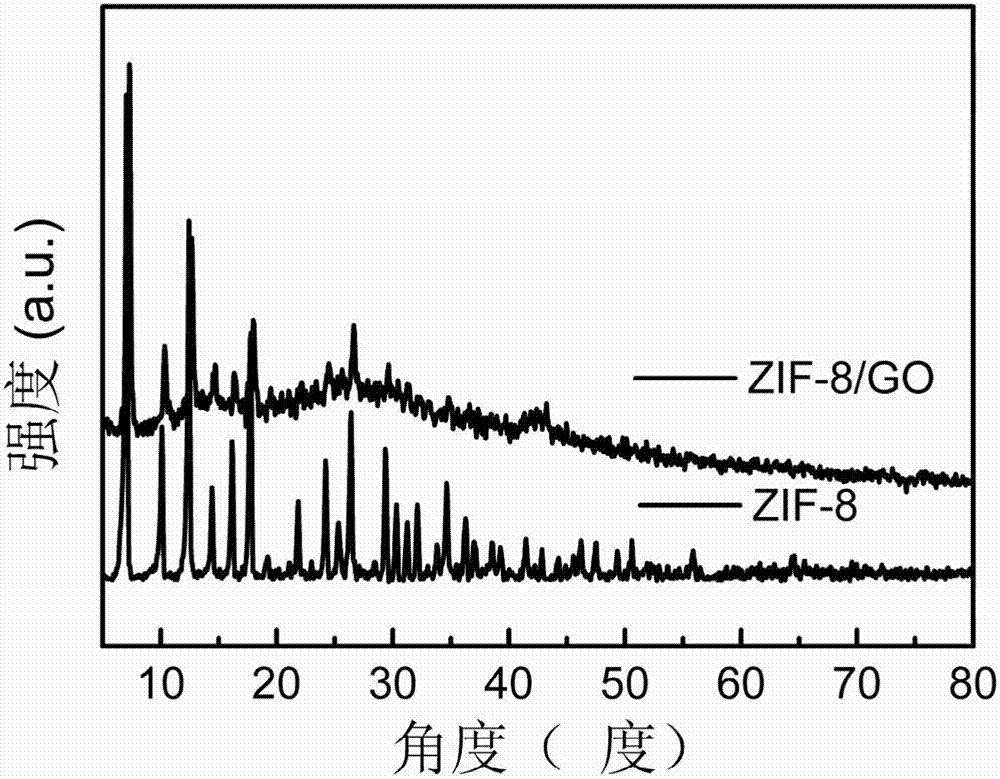

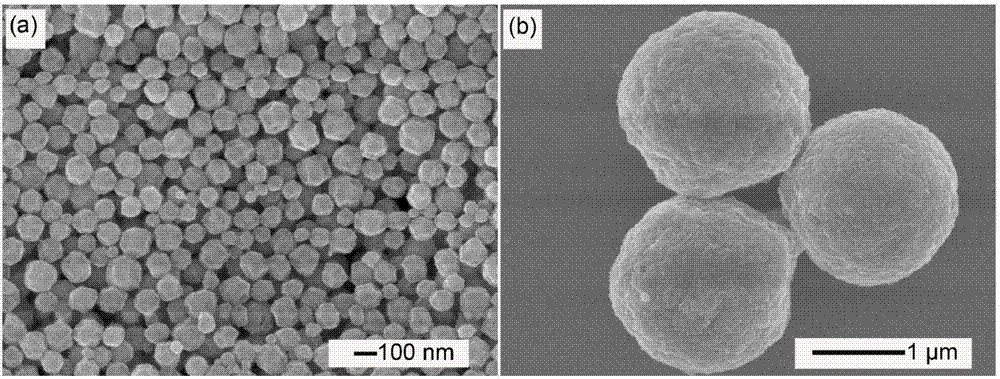

[0035] X-ray diffraction patterns of ZIF-8 and the prepared ZIF-8 / GO composite microspheres are as follows: figure 1 As s...

Embodiment 2

[0039] A method for preparing metal-organic framework compound / graphene oxide composite microspheres with uniform appearance, the steps are as follows:

[0040] Disperse ZIF-8 and graphene oxide in deionized water respectively to prepare a ZIF-8 dispersion with a concentration of 2 mg / mL and a graphene oxide dispersion with a concentration of 2 mg / mL, and slowly add ZIF-8 to the graphene oxide In the dispersion liquid, stir while adding it, the mixing ratio is 2:1, and then spray dry the obtained mixed liquid. The spray drying conditions are: the inlet air temperature is 150°C, the feeding speed is adjusted by a peristaltic pump, and the feeding speed is 10mL / min, the compressed air flow rate is 600L / h, the compressed air pressure is 5-8bar, and the airflow velocity is 35m 3 / h, and the outlet air temperature was 80°C to prepare ZIF-8 / GO composite microspheres.

Embodiment 3

[0042] A method for preparing metal-organic framework compound / graphene oxide composite microspheres with uniform appearance, as shown in Example 1, the difference is:

[0043] The spray drying conditions are: the inlet air temperature is 160°C, the feed rate is adjusted by a peristaltic pump, the feed rate is 12mL / min, the compressed air flow rate is 1000L / h, the compressed air pressure is 5-8bar, and the outlet air velocity is 35m 3 / h, the outlet air temperature is 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com