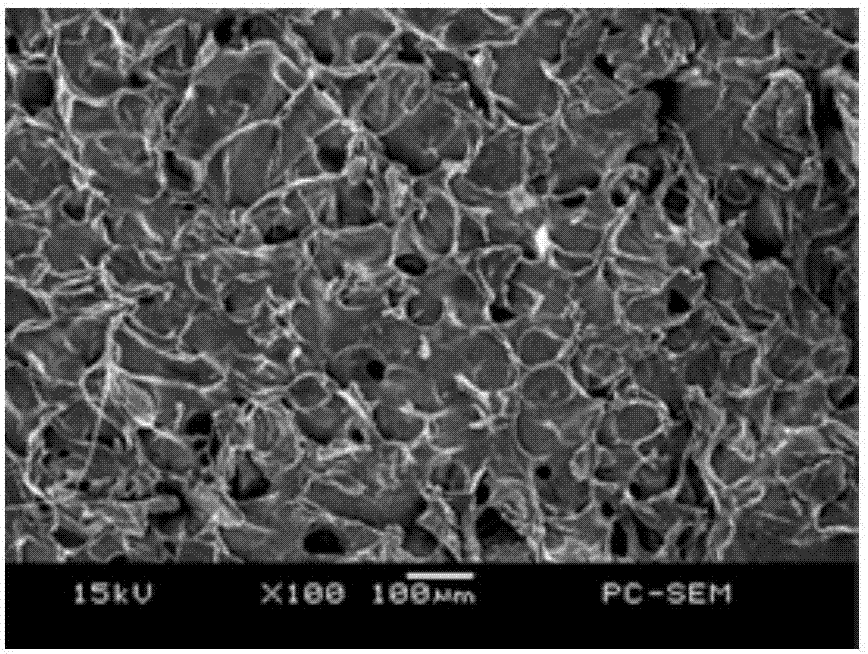

Anti-sticking wet dressing for promoting healing of burn wound and preparation method of anti-sticking wet dressing

A wet dressing and wound healing technology, applied in medical science, absorbent pads, bandages, etc., can solve problems such as wound adhesion, achieve the effects of avoiding infection, automatically adjusting swelling balance, and reducing inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of this embodiment comprises the following steps:

[0043] (1) sodium carboxymethyl cellulose is dissolved in propylene glycol deionized aqueous solution by mass volume percentage 2.0% (the quality of sodium carboxymethyl cellulose and the volume percentage of propylene glycol aqueous solution are 2.0%, other embodiments are also the same), Prepare sodium carboxymethyl cellulose / propylene glycol aqueous solution; wherein, in the propylene glycol deionized aqueous solution, the mass percentage concentration of propylene glycol and deionized water is 1.0%, the stirring speed is 500r / min during preparation, and the stirring time is 1.5h. Keep the solution temperature at 30 °C.

[0044] (2) Sodium alginate is dissolved in the sodium carboxymethyl cellulose / propylene glycol aqueous solution prepared in step (1) by mass volume percentage 2.0% (the quality of sodium alginate and the sodium carboxymethyl cellulose and propylene glycol mixed solution prepa...

Embodiment 2

[0048] The preparation method of this embodiment is as follows:

[0049] (1) Sodium carboxymethyl cellulose is dissolved in propylene glycol deionized aqueous solution by mass volume percentage 2.0%, is mixed with sodium carboxymethyl cellulose / propylene glycol aqueous solution; Wherein, in propylene glycol deionized aqueous solution, the quality of propylene glycol is the same as that of deionized water The volume percentage concentration is 1.0%, the stirring speed is 500r / min, the stirring time is 1.5h, and the solution temperature is kept at 30°C

[0050] (2) Sodium alginate is dissolved in the sodium carboxymethyl cellulose / propylene glycol aqueous solution prepared in step (1) according to the mass volume percentage of 3.0%, and is prepared into a sodium carboxymethyl cellulose / sodium alginate / propylene glycol colloidal solution; wherein, when preparing The stirring speed was 500r / min, the stirring time was 1.5h, and the temperature of the solution was kept at 30°C.

[...

Embodiment 3~10

[0054] The difference between Examples 3-10 and Example 1 is that the mass volume percentage of propylene glycol, sodium carboxymethyl cellulose, sodium alginate and chitosan are different by mass volume percentage when preparing the solution, as shown in Table 1. Other operations are the same.

[0055] The mass volume percentage concentration of four kinds of substances in the solution prepared by the embodiment 1~10 of table 1

[0056] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com