All-solid-state large-mode-area near-zero dispersion-flattened microstructure optical fiber

A technology of micro-structured optical fiber and flat dispersion, which is applied in the direction of glass optical fiber, clad optical fiber, multi-layer core/clad optical fiber, etc., and can solve the problems of air hole collapse, affecting system performance, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

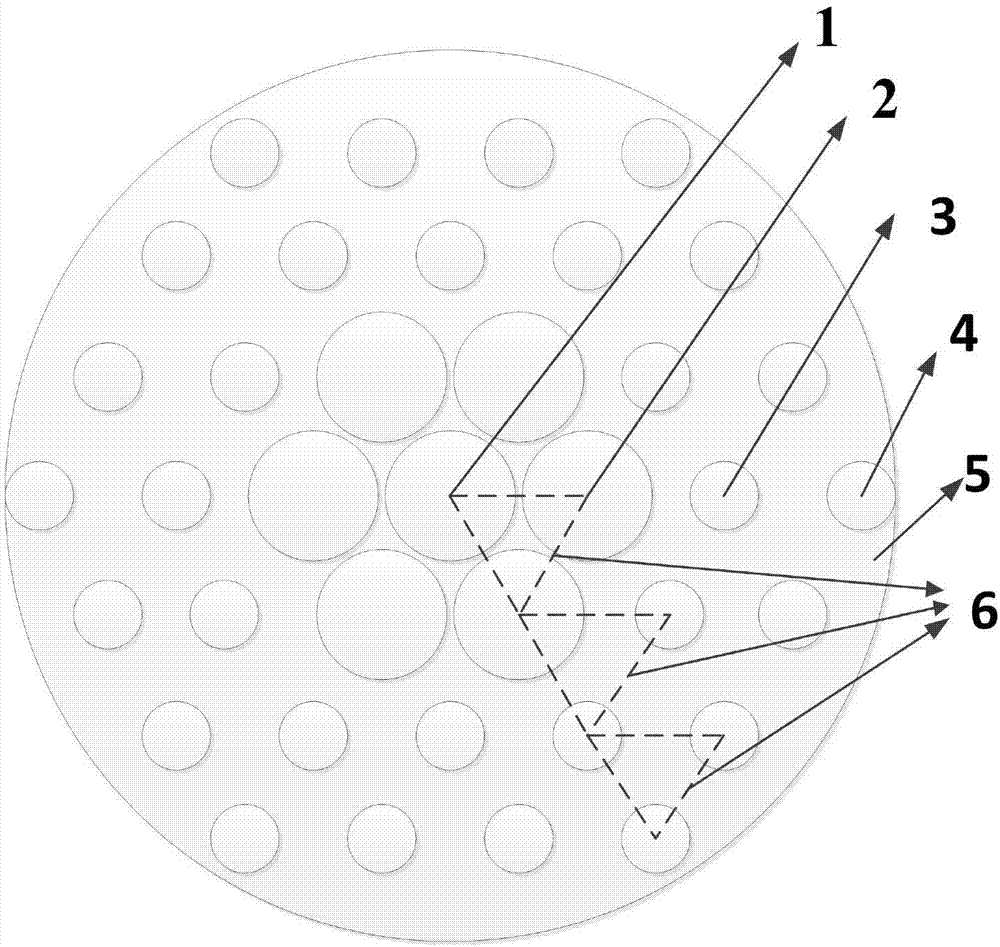

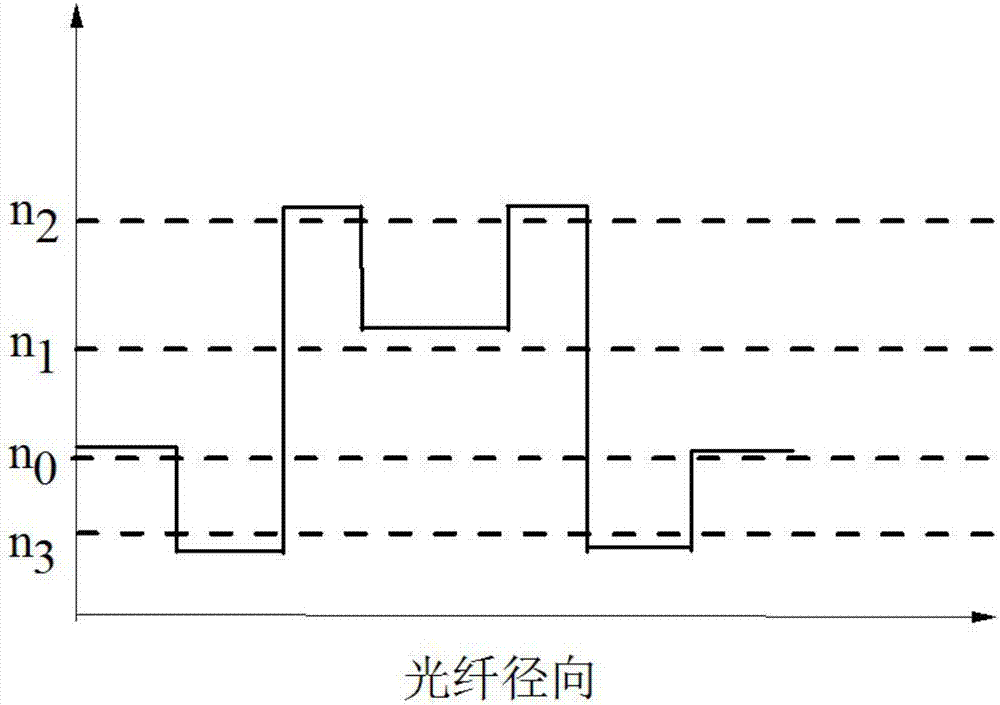

[0032] Embodiment 1: The fiber core part introduces high-doped quartz columns, and the radius r of the first and second layers of high-doped quartz columns 1 and 2 1 =1220nm, refractive index n 1 =1.451; the radius r of the third layer of highly doped quartz column 3 in the core area 2 =650nm, refractive index n 2 =1.454, cladding low-doped quartz column 4, refractive index n 3 =1.435, the radius is 640nm. The pillar spacing Λ of the quartz pillars in the core region and the cladding region is 2600nm.

Embodiment 2

[0033] Embodiment two: the fiber core part introduces highly doped quartz columns, the radius r of the first and second layers of highly doped quartz columns 1 and 2 1 =1320nm, refractive index n 1 =1.453; the radius r of the third layer of highly doped quartz column 3 in the core area 2 =750nm, refractive index n 2 =1.456, cladding low-doped quartz column 4, refractive index n 3 =1.445, the radius is 740nm. The pillar spacing Λ of the quartz pillars in the core region and the cladding region is 2700nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius r | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com