Three-dimensional drying device

A drying device and three-dimensional technology, applied in the field of three-dimensional drying devices, can solve the problems of high labor intensity, low degree of automation, and non-concentrated heat consumption, etc., and achieve the effects of improving drying efficiency, saving space, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

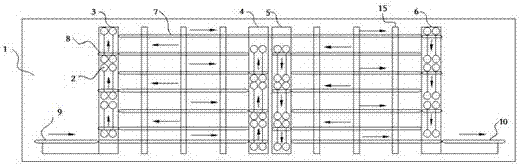

[0017] Such as figure 1 As shown, a three-dimensional drying device of the present invention adopts a mechanism for three-dimensional circulation transmission of the workpiece installed in the drying chamber 1, and prolongs the distance of the workpiece transmission in a limited space so that it is fully and closely connected with the indoor drying air. Even contact improves drying efficiency and drying uniformity.

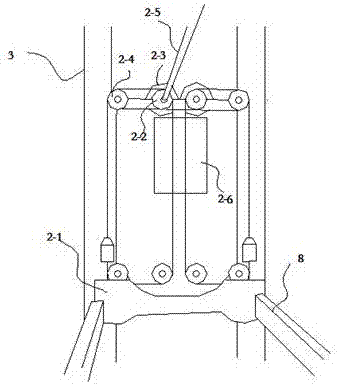

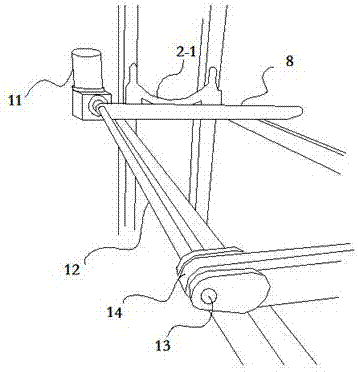

[0018] It specifically includes a drying chamber 1. Several supporting columns are arranged in the drying chamber 1. Several layers of horizontal brackets are arranged side by side between the supporting columns, and the main transmission frame 7 with a sprocket transmission system is fixed on each layer of horizontal brackets. , the outer sides of the two adjacent horizontal brackets up and down are staggered with a lifting transmission frame 8 with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com