Heat-saving power-saving control method for high-low-region direct connecting unit

A unit and heat-saving technology, applied in heating methods, high-efficiency regulation technology, household heating, etc., can solve the problems of wasting electric energy, difficult to achieve quality control, wasting heat energy, etc., and achieve the effect of meeting the demand of heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

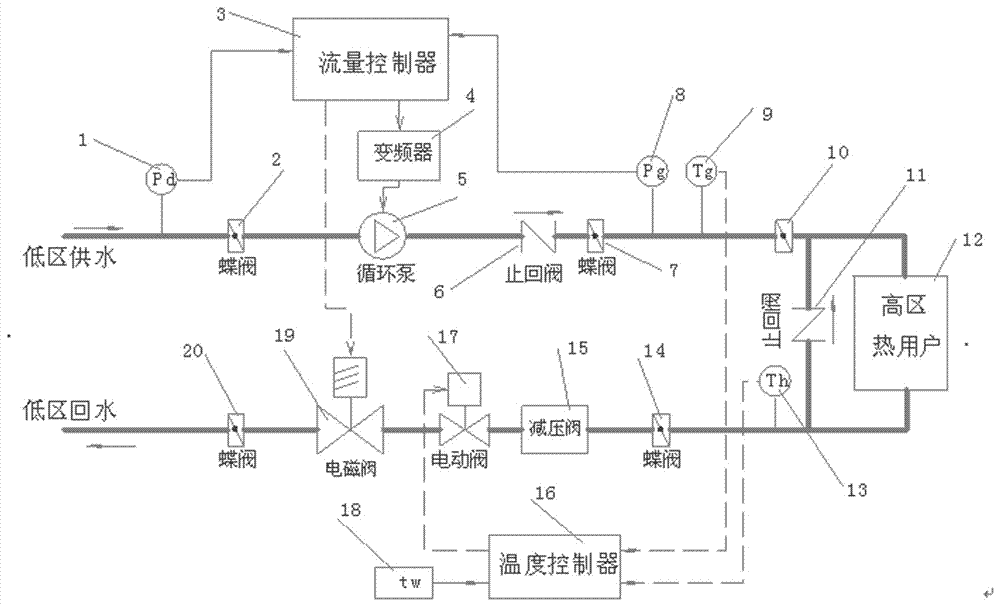

[0014] Below in conjunction with embodiment and accompanying drawing, the method of the present invention is further elaborated:

[0015] A heat-saving and power-saving control method for directly connected units in high and low areas, comprising the following steps:

[0016] Step 1, collect the outdoor temperature to generate and calculate the average temperature of the supply and return water;

[0017] Step 2, collect the actual supply and return water temperature to form the actual supply and return water average temperature;

[0018] Step 3: Compare the actual average temperature of the supply and return water with the calculated average temperature of the supply and return water, and control the opening of the two-way electric valve installed from the return water pipe in the high area to the top through the PID control method, and then control the hot water flow of the unit in the high and low areas to form the average temperature Closed-loop feedback control to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com