Hybrid power engineering machine multi-actuator control system

A control system and construction machinery technology, applied in mechanical equipment, fluid pressure actuators, servo motors, etc., can solve problems such as system heat generation, large pressure loss, and poor controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

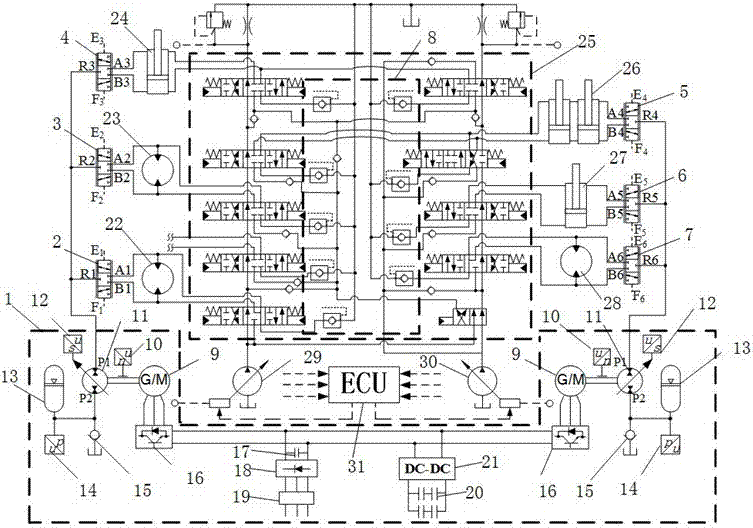

[0032] Implementing the above-mentioned hybrid power construction machinery multi-actuator control system provided by the present invention, as shown in the attached figure 1 As shown, it includes a double-pump double-circuit hydraulic control system, which is characterized in that it is additionally equipped with a back pressure adjustment unit 1, a first conversion control valve 2, a second conversion control valve 3, a third conversion control valve 4, and a fourth conversion control valve. Valve 5, fifth switching control valve 6, sixth switching control valve 7, hydraulic control one-way valve group 8;

[0033]The first working oil port A1 of the first conversion control valve 2 communicates with the first working oil port of the left traveling hydraulic motor 22, and the second working oil port B1 communicates with the second working oil port of the left traveling hydraulic motor 22;

[0034] The first working oil port A2 of the second conversion control valve 3 communic...

Embodiment 2

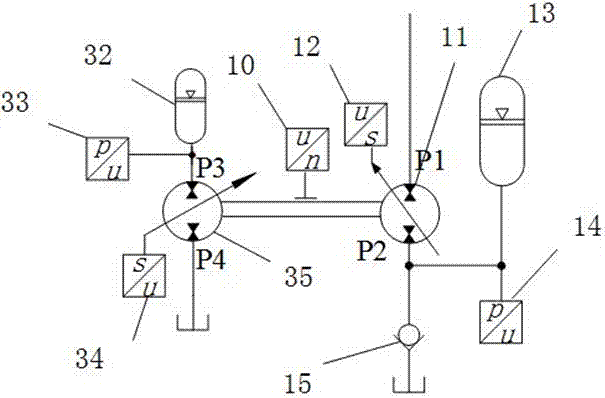

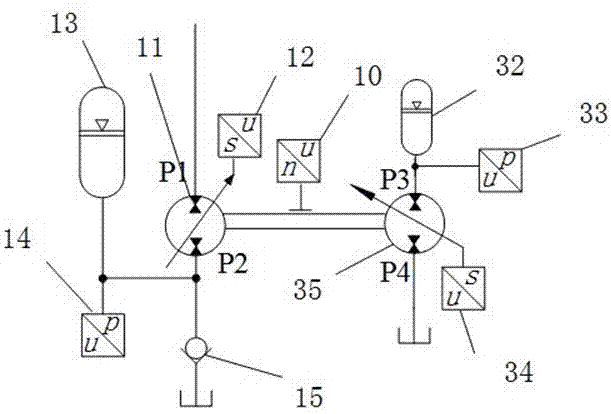

[0046] Implementing the above-mentioned hybrid power construction machinery multi-actuator control system provided by the present invention, as shown in the attached figure 2 , attached image 3 As shown, it includes a double-pump double-circuit hydraulic control system, which is characterized in that it is additionally equipped with a back pressure adjustment unit 1, a first conversion control valve 2, a second conversion control valve 3, a third conversion control valve 4, and a fourth conversion control valve. Valve 5, fifth switching control valve 6, sixth switching control valve 7, hydraulic control one-way valve group 8;

[0047] The first working oil port A1 of the first conversion control valve 2 communicates with the first working oil port of the left traveling hydraulic motor 22, and the second working oil port B1 communicates with the second working oil port of the left traveling hydraulic motor 22;

[0048] The first working oil port A2 of the second switching co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com