Plastering construction method for wall base layer

A wall and base technology, applied in covering/lining, building, building structure, etc., can solve the problems of untimely maintenance of plastering layer, poor roughening quality, and insufficient maintenance time, so as to ensure the quality and time of the project Finished, the effect of the wall surface is good, and the effect of improving the social image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The wall base plastering construction method of the present embodiment comprises the following steps successively:

[0037] (1) Clean the surface of the wall;

[0038] In this step (1), the dust, oil stains, oil stains, residual mortar and other impurities attached to the surface of the wall must be removed; in specific operations, the sundries, dust and residues attached to the surface of the wall can be removed with a brush If necessary, cleanser can be used to deal with oil stains and oil stains;

[0039] (2) Spray water on the surface of the wall (after cleaning the surface of the wall and before roughening the surface of the wall, spray water one day in advance) to make the surface of the wall wet;

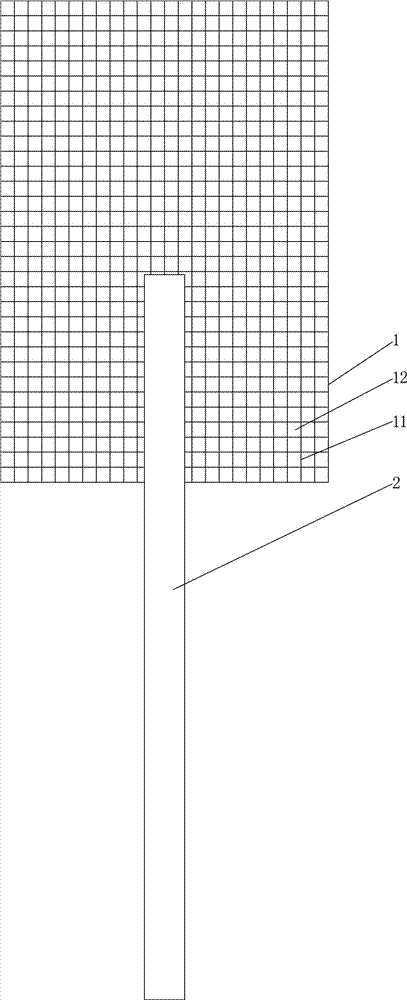

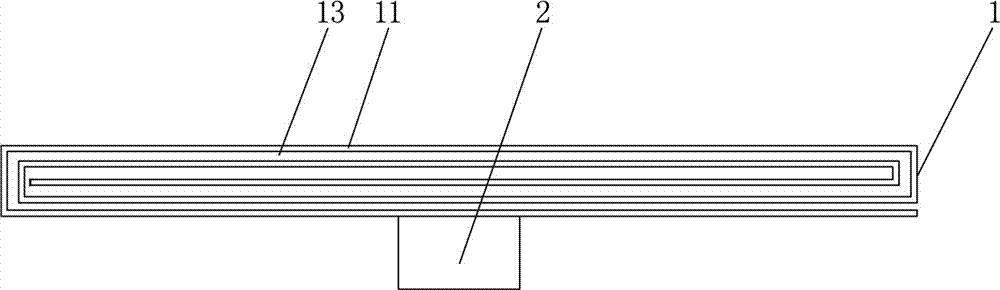

[0040] (3) Wall surface roughening treatment

[0041] Beat the cement mortar on the surface of the wall with a beating device, and the cement mortar solidifies to form a textured layer, which is composed of multiple protrusions covered on the surface of the wall;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com