Production method and production system of super-clean high-octane number gasoline

A production method and gasoline technology, which are applied in the fields of hydrocarbon oil treatment products, chemical instruments and methods, and refined hydrocarbon oil, etc., can solve the problems of complex process flow and low liquid yield of gasoline products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

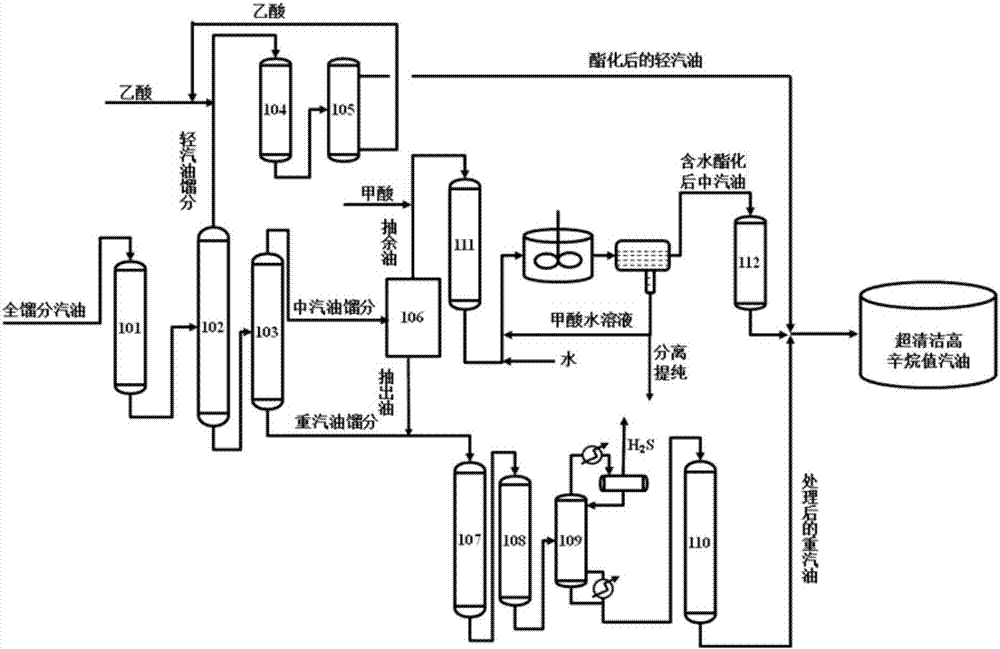

Embodiment 1

[0095] This embodiment provides a sulfur content of 625.3μg·g -1 , 35.6v% olefin content, 14.4v% aromatics content, 18.2v% isoparaffin content, 0.7v% benzene content FCC gasoline (full distillate gasoline, raw material oil 1) is used as raw material for hydroreforming treatment to produce ultra-low sulfur The high-octane gasoline method.

[0096] Wherein, based on the total weight of each catalyst, the composition ratio of each catalyst is as follows:

[0097] Oriented sulfur transfer catalyst: 12wt.% NiO, 6wt.% MoO 3 , 2wt.% La 2 o 3 , 20wt.% stepped hole HZSM-5, 60wt.% Al 2 o 3 -SiO 2 (silicon-containing alumina);

[0098] Light gasoline esterification catalyst: 40wt.% HZSM-5, 60wt.% Al 2 o 3 -SiO 2 (silicon-containing alumina);

[0099] Medium gasoline esterification catalyst: 50wt.% HZSM-5, 50wt.% Al 2 o 3 -SiO 2 (silicon-containing alumina);

[0100] Medium gasoline extraction solvent: 90wt.% sulfolane and 10wt.% tetraethylene glycol;

[0101] One-stage se...

Embodiment 2

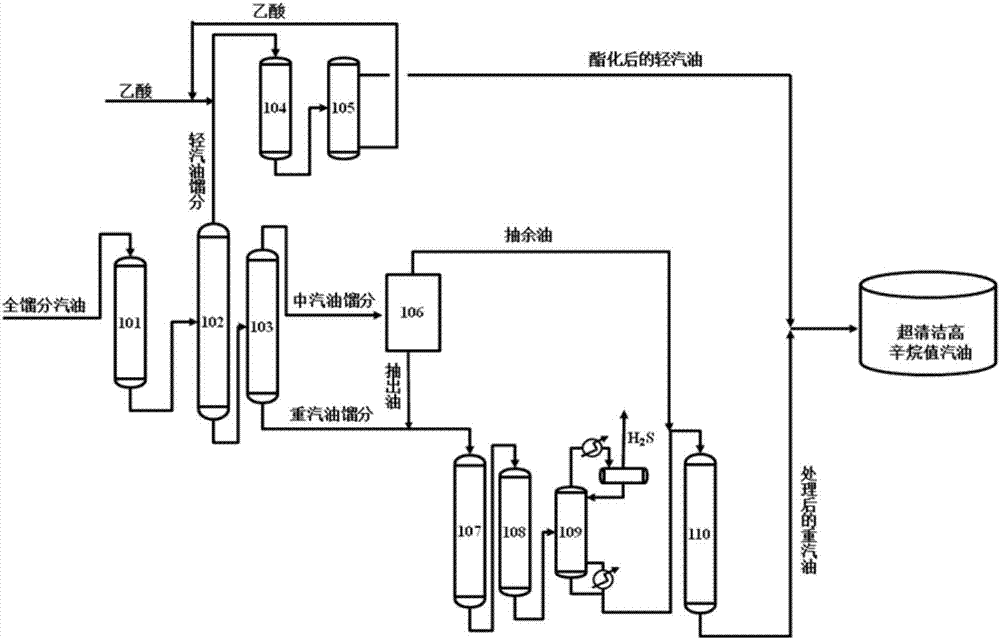

[0147] This embodiment provides a method and system for producing ultra-clean high-octane gasoline using the aforementioned feedstock 1 as a raw material.

[0148] Such as figure 2 As shown, the system of this embodiment is basically the same as that of Embodiment 1, except that the raffinate outlet of the extraction and distillation system 106 is not connected to the reaction raw material inlet of the medium gasoline esterification reactor 111 but is directly connected to the The reaction raw material inlet of the hydrocarbon isomerization / aromatization reactor 110; that is, the system of this embodiment does not have the medium gasoline esterification reactor 111, the formic acid extraction system and the coalescence dehydrator 112, but the extraction distillation system The raffinate outlet of 106 is directly connected to the reaction raw material inlet of the hydrocarbon isomerization / aromatization reactor 110 through pipelines, and the rest are the same as the aforementi...

Embodiment 3

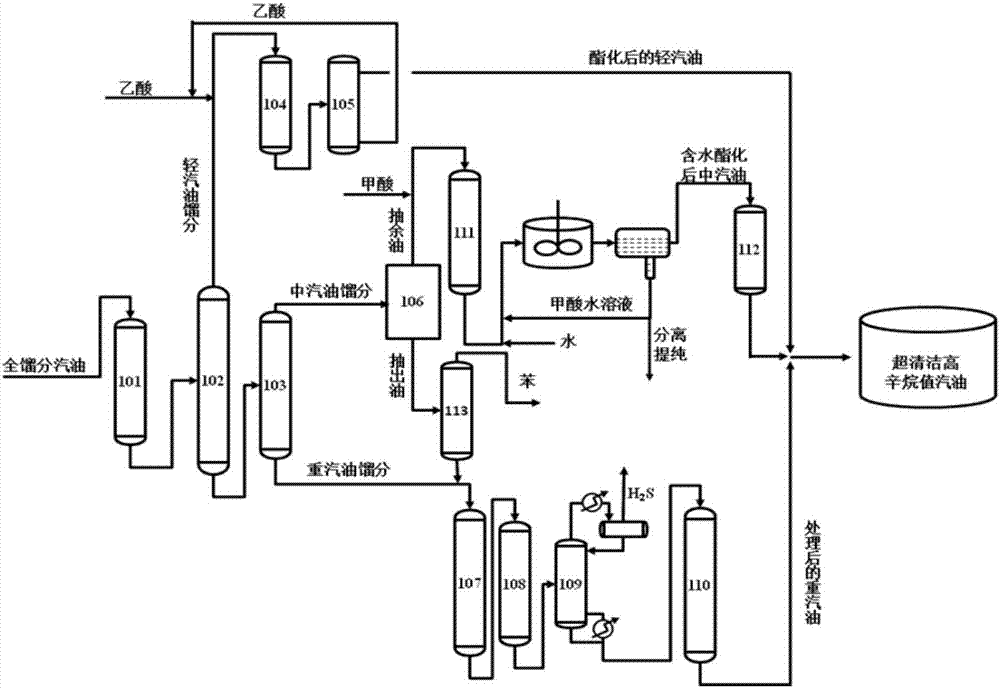

[0154] This embodiment provides a sulfur content of 1230.0μg·g -1 , olefin content 42.3v%, aromatics content 20.3v%, isoparaffin content 20.2v%, benzene content 1.5v% high sulfur, high olefin, high benzene FCC gasoline (stock oil 2, its properties see Table 3) as raw material A method and system for producing ultra-clean high-octane gasoline.

[0155] Such as image 3 As shown, the system of this embodiment is basically the same as that of Embodiment 1, only a debenzene tower 113 is set on the pipeline between the extraction oil outlet of the extraction distillation system 106 and the reaction material inlet of the first-stage hydrodesulfurization reactor 107, The outlet of the extracted oil after debenzene removal in the debenzene tower 113 is connected to the first-stage hydrodesulfurization reactor 107, and the rest are the same as in Example 1.

[0156] The method of producing ultra-clean high-octane gasoline using feedstock 2 is as follows:

[0157] Compatible with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com