Water spraying device for composite insulator of overhead line

A technology of composite insulators and water spray devices, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of heavy workload, inconvenient carrying, and no structure with a stable center of gravity, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

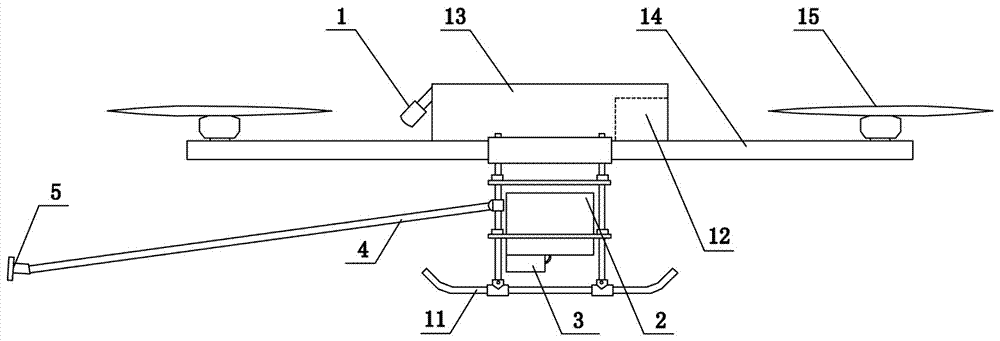

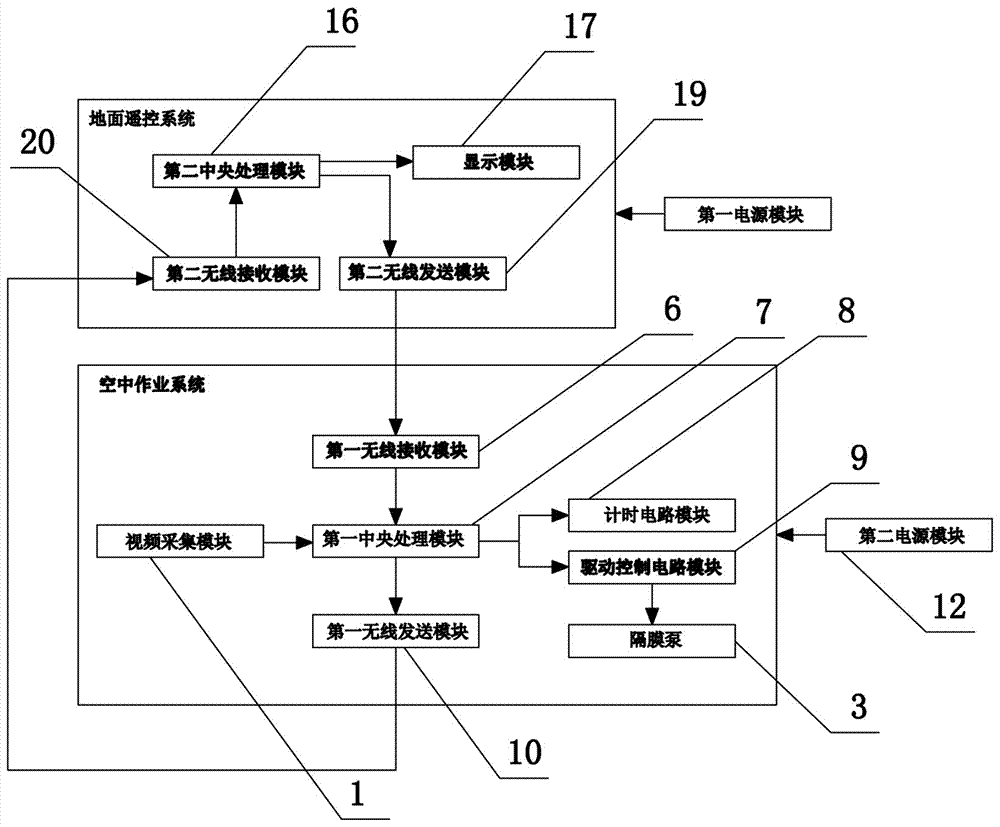

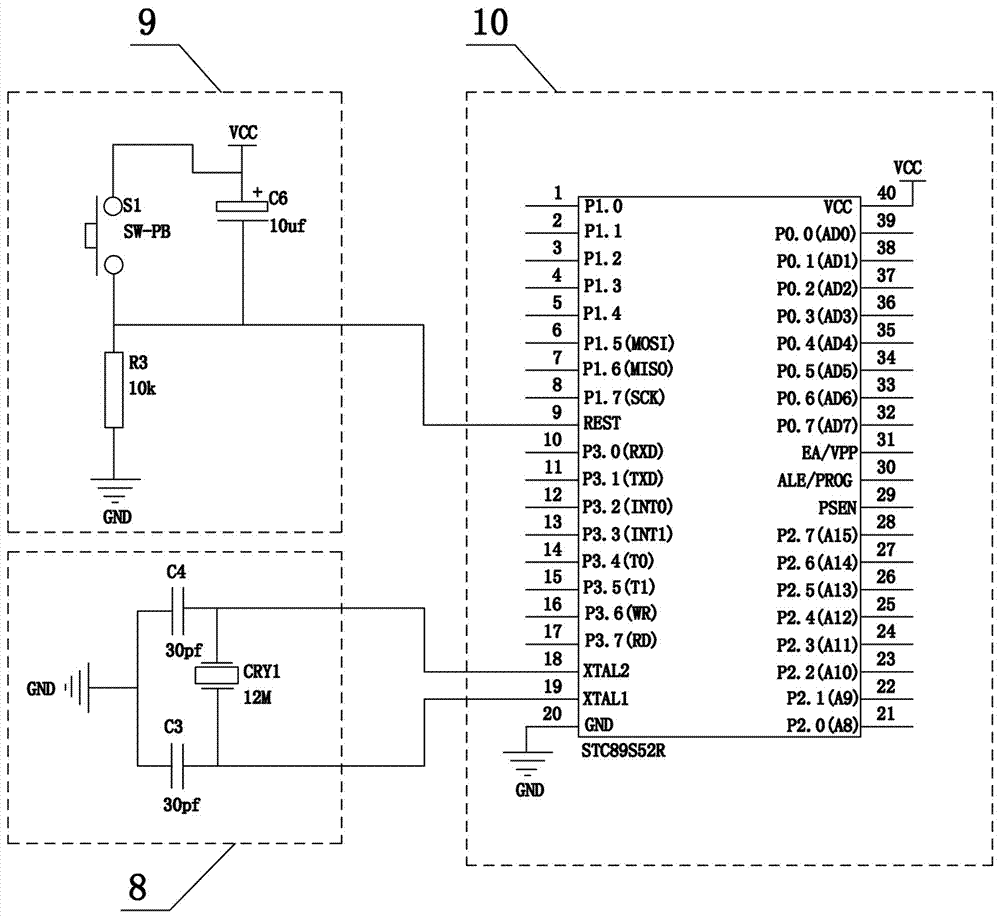

[0031] Such as Figure 1 to Figure 3 As shown, the present invention includes a two-way wireless communication aerial operation system and a ground remote control system. The aerial operation system includes a drone, a water spray mechanism and a video acquisition module 1 arranged on the drone, and the water spray mechanism includes a water tank 2 and a diaphragm pump. 3. The water guide pipe 4, the mist nozzle 5 and the automatic control module, the water tank 2 is a cylindrical structure, the water inlet of the diaphragm pump 3 is arranged below the water tank 2, and one end of the water guide pipe 4 communicates with the water outlet of the diaphragm pump 3, The other end of the water guide pipe 4 is connected with the spray nozzle 5, and the automatic control module includes a first wireless receiving module 6, a first central processing module 7, a timing circuit module 8, a drive control circuit module 9 and a first wireless sending module 10, The output end of the firs...

Embodiment 2

[0035] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 4 As shown, the propellers of each support arm 14 include an upper propeller 21 and a lower propeller 22. Both the upper propeller 21 and the lower propeller 22 provide lifting force and are installed at different positions of the same support arm 14. The two-layer design effectively improves the load capacity of the present invention. load, so that the present invention carries a water tank 2 with a larger volume and increases the number of insulators to be detected.

Embodiment 3

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 5 As shown, the inner bottom of the water tank 2 is provided with three annular water retaining pieces 23, and the heights of the three annular water retaining pieces 23 increase sequentially from the inside to the outside. A plurality of through holes 24 are uniformly arranged on the lower part of the water blocking sheet 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com