A method for fault diagnosis and additive repair of ship mooring system

A technology for fault diagnosis and mooring system, applied in the direction of instrument, geometric CAD, calculation, etc., can solve the problem of lack of research on the accuracy of ship mooring system, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

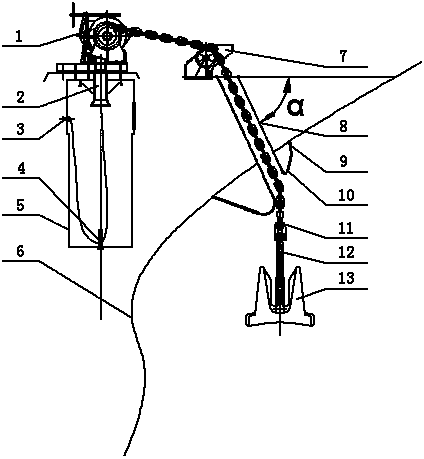

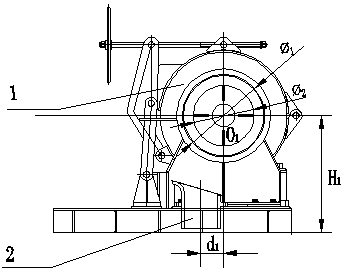

[0031] The mooring system of the ship in this embodiment is arranged on the hull 6, such as figure 1 As shown, an anchor seat 13 is provided on the hull 6, and an anchor shackle 12 and a light ring 11 are provided on the anchor seat 13, and the windlass 1 is connected to the windlass 1 through the guide chain roller 7, and the anchor chain is fixedly connected to the bottom of the windlass 1. The chain locker 5 is provided with the chain locker entrance 2, the anchor abandonment device 3 and the chain lock eye ring 4 sequentially from top to bottom in the chain locker 5; the chain drum is arranged outside the chain guide wheel on the side close to the hull 6 8, and the hull 6 is also provided with an anchor platform 9, and through the anchor platform 9, an anchor lip 10 connected to the chain cylinder 8 is provided.

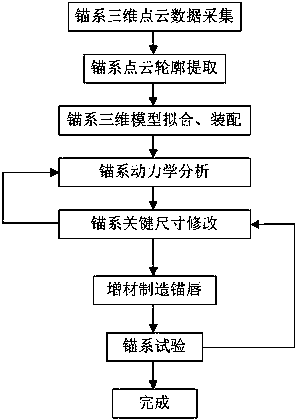

[0032] The method for fault diagnosis and additive repair of ship mooring systems in this embodiment mainly uses three-dimensional scanning reverse engineering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com